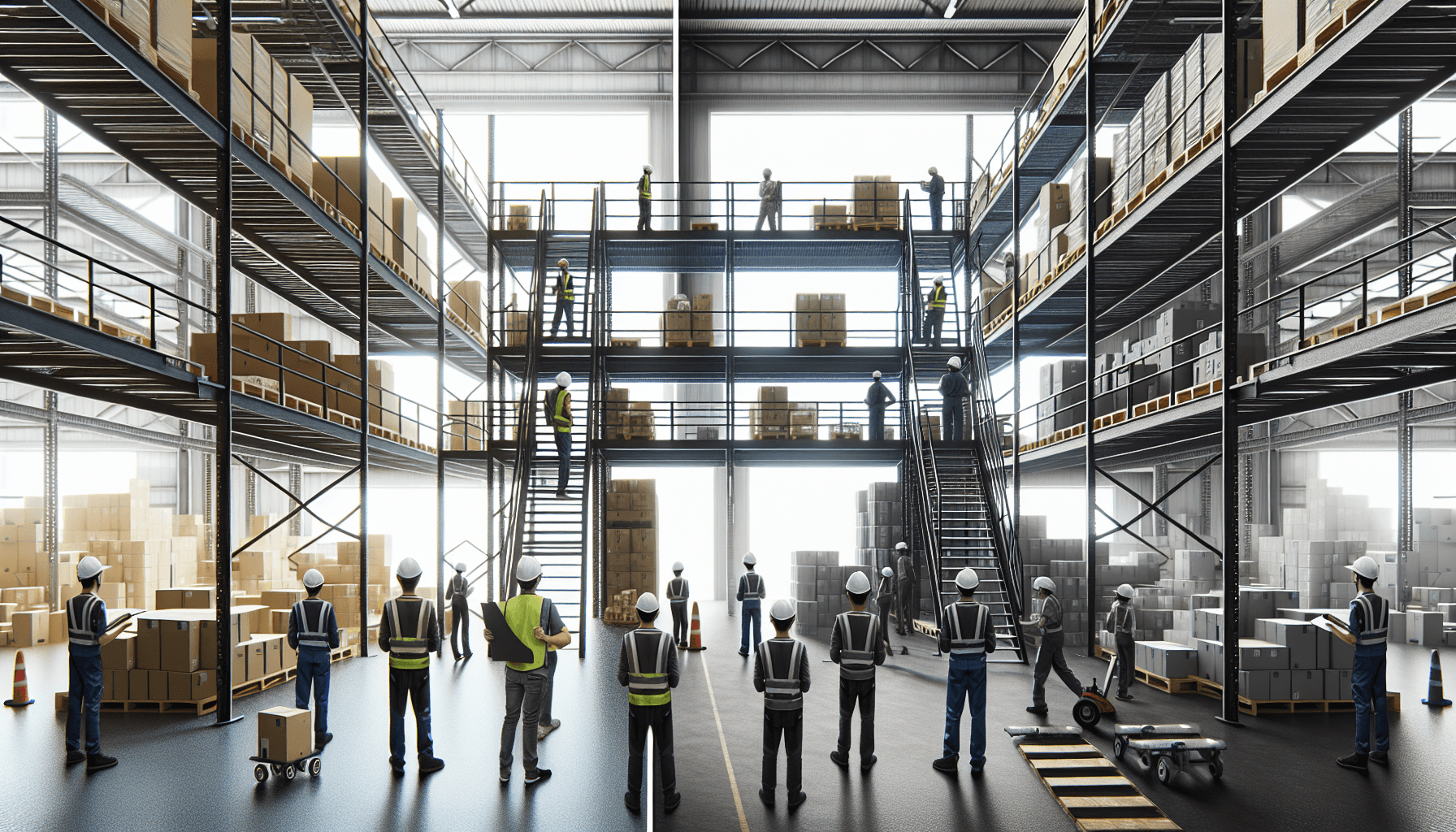

Warehouse mezzanines and platforms play a crucial role in optimizing the storage space and enhancing operational efficiency in warehouses. However, it is imperative to ensure the safety of these structures to prevent accidents and injuries. In this article, we will explore how to evaluate the safety of warehouse mezzanines and platforms, and the key factors to consider.

Proper Installation and Design

The first and foremost aspect to consider when evaluating the safety of warehouse mezzanines and platforms is their proper installation and design. It is essential to ensure that these structures are installed by experienced professionals who follow industry standards and regulations.

The design of the mezzanine and platform should also be in compliance with the local building codes and safety regulations. The load-bearing capacity of the structure, including the columns, beams, and flooring, should be calculated accurately to handle the expected weight and traffic. It is recommended to consult with a structural engineer to ensure the design meets all safety requirements.

Regular inspections should be conducted to check for any signs of wear and tear, corrosion, or damage that might compromise the structural integrity of the mezzanine or platform. Any necessary repairs or replacements should be promptly addressed to maintain the safety of the structure.

Guardrail Systems

One of the most critical safety features for warehouse mezzanines and platforms is the installation of appropriate guardrail systems. Guardrails serve as protective barriers to prevent falls from elevated heights. These guardrail systems should be designed and installed according to the relevant safety regulations.

The guardrails should be sturdy, with sufficient height and strength to withstand potential force or impact. The gaps between the railings should also be appropriately spaced to prevent items or employees from slipping through. Regular inspections should be carried out to ensure there are no loose or damaged railings, and any issues should be addressed promptly.

Additionally, it is highly recommended to have toe boards installed along the edges of the mezzanines and platforms. Toe boards help prevent objects from falling and provide an additional level of protection against accidents.

Safe Access and Egress

Safe access and egress are crucial when evaluating the safety of warehouse mezzanines and platforms. Employees and workers should be able to access these elevated areas safely and efficiently. This includes having proper staircases, ladders, or ramps that are correctly designed, constructed, and maintained.

The staircases should have appropriate handrails that are securely attached to provide stability and support while climbing up or down. The steps should be non-slip and well-maintained, preventing any potential tripping hazards.

Additionally, it is essential to have clear signage indicating the pathways to the mezzanines and platforms, emergency exits, and evacuation routes. Proper lighting should also be installed to ensure good visibility and minimize the risk of accidents.

Employee Training and Education

Another crucial aspect of evaluating the safety of warehouse mezzanines and platforms is to ensure that employees are adequately trained and educated on proper usage and safety procedures. Employees should undergo training programs that educate them about the potential hazards, safety protocols, and emergency procedures specific to working on or around mezzanines and platforms.

Training should cover topics such as load capacity limitations, proper stacking and storage of materials, the correct use of equipment like forklifts or pallet jacks, and the importance of maintaining a clutter-free work area. Employees should also be educated on the importance of reporting any safety concerns or incidents promptly.

Regular refresher training sessions should be conducted to reinforce safety practices and ensure employees are always up to date with the latest protocols and procedures.

Conclusion

Evaluating the safety of warehouse mezzanines and platforms is essential to ensure the well-being of employees, prevent accidents, and maintain efficient operations. By focusing on proper installation and design, guardrail systems, safe access and egress, and employee training, warehouse managers can create a safer working environment.

Remember to consult with professionals and experts in warehouse safety, such as HCO Innovations, to ensure that your warehouse mezzanines and platforms meet and exceed all safety requirements. By prioritizing safety, you can create a workspace where employees can perform their duties effectively, while minimizing the risk of injuries or accidents.

What is a warehouse mezzanine?

A warehouse mezzanine is an elevated platform or structure that is installed within a warehouse or industrial facility to create additional floor space.

Why should I evaluate the safety of warehouse mezzanines and platforms?

Evaluating the safety of warehouse mezzanines and platforms is crucial to ensure the well-being of employees and prevent accidents or injuries caused by structural instability or inadequate safety measures.

What are some key factors to consider when evaluating the safety of warehouse mezzanines and platforms?

When evaluating the safety of warehouse mezzanines and platforms, important factors to consider include load capacity, structural integrity, proper installation, safety railings and barriers, fire protection measures, and compliance with local safety regulations.

How can I determine the load capacity of a warehouse mezzanine?

To determine the load capacity of a warehouse mezzanine, you should consult the manufacturer's specifications and guidelines. Alternatively, you can hire a structural engineer to assess the capacity based on the materials used, design, and intended usage of the mezzanine.

What should I look for when assessing the structural integrity of a warehouse mezzanine?

When assessing the structural integrity of a warehouse mezzanine, look for signs of structural damage, such as rust, cracks, or excessive wear. Additionally, ensure that all supporting beams, columns, and connections are properly aligned and securely fastened.

Are there any specific safety standards or regulations related to warehouse mezzanines and platforms?

Yes, there are specific safety standards and regulations that govern warehouse mezzanines and platforms. These may vary by region or country. It is important to familiarize yourself with the applicable codes, such as OSHA (Occupational Safety and Health Administration) standards in the United States, and ensure compliance with all relevant regulations.

How often should I conduct safety inspections for warehouse mezzanines and platforms?

Regular safety inspections for warehouse mezzanines and platforms should be conducted at least annually. However, it is recommended to also perform periodic inspections whenever there are changes in usage, modifications to the structure, or if any safety concerns arise.

What safety features should be in place for warehouse mezzanines and platforms?

Warehouse mezzanines and platforms should be equipped with safety features such as handrails, guardrails, kick plates, and safety gates to prevent falls. Additionally, fire protection measures, adequate lighting, and clear signage should be in place to ensure overall safety within the work area.

Can I modify or expand an existing warehouse mezzanine?

Modifying or expanding an existing warehouse mezzanine should only be done after consulting with a qualified engineer or mezzanine manufacturer. Approaching such modifications without proper expertise may compromise the structural integrity and safety of the mezzanine.

What are the consequences of not evaluating the safety of warehouse mezzanines and platforms?

Failing to evaluate the safety of warehouse mezzanines and platforms can lead to accidents, injuries, damage to goods or property, legal liabilities, and potential fines or penalties for non-compliance with safety regulations. It is essential to prioritize safety to protect both employees and the business itself.

Safe Working Practices for Warehouse Forklift Operators.

The warehouse is a bustling hub of activity, where efficient material handling is paramount for smooth operations and cost savings. Forklift operators play a crucial role in ensuring the safe movement of goods and materials within the warehouse. In this article, we will discuss the importance of safe working practices for warehouse forklift operators, and how HCO Innovations can help you optimize your forklift fleet management.

Why Safe Working Practices Matter

Warehouse forklift operators need to prioritize safety in their daily operations for several important reasons:

- Protecting employees: Safety should always be the top priority in the workplace. Following safe working practices helps to prevent accidents, injuries, and fatalities, ensuring the well-being of forklift operators and other warehouse personnel.

- Minimizing property damage: Forklifts can cause significant damage to goods, equipment, and infrastructure if not operated in a safe manner. Employing safe practices reduces the risk of accidents and costly repairs.

- Compliance with regulations: Warehouse operations need to comply with various safety regulations and guidelines. Adhering to these regulations not only prevents penalties but also demonstrates a commitment to creating a safe working environment.

Now, let's explore some essential safe working practices for warehouse forklift operators:

1. Proper Forklift Training

Before operating a forklift, operators should receive comprehensive training covering the safe operation of the specific type of forklift they will be using. Training programs should include:

- Basic forklift operation techniques

- Load handling and stacking techniques

- Safe operating speeds and maneuvering

- Pre-operation inspections and maintenance

- Tips for operating in different warehouse environments

HCO Innovations offers forklift operator training programs that can equip your workforce with the necessary skills and knowledge to operate forklifts safely and efficiently. Our training is tailored to your specific industry and warehouse requirements, ensuring a comprehensive understanding of safe practices.

2. Regular Forklift Inspections and Maintenance

Proper maintenance and regular inspections of forklifts are crucial for identifying potential hazards and ensuring safe operation. Forklift operators should conduct pre-operation inspections, checking for any visible damage, malfunctioning parts, or fluid leaks.

HCO Innovations can assist you in establishing a turnkey maintenance solution for your forklift fleet. We leverage advanced cost-tracking software to proactively schedule and track maintenance activities, reducing the risk of sudden breakdowns and costly repairs.

3. Clear Communication and Signage

Effective communication is vital to maintaining a safe working environment. Forklift operators should use clear hand signals, horns, and audible warnings to communicate with pedestrians and other forklift operators. Additionally, maintaining proper signage throughout the warehouse, including speed limits and designated pedestrian zones, helps to prevent accidents and promote awareness.

HCO Innovations can help you evaluate your warehouse layout and suggest improvements for optimizing traffic flow and enhancing safety. Our experts can assist in implementing clear signage and designated areas for pedestrians, creating a safer environment for everyone.

4. Proper Load Handling and Stacking Techniques

Safe load handling is crucial for maintaining balance and stability while operating a forklift. Forklift operators should be trained to properly position loads, evenly distribute weight, and secure them with appropriate restraints. Additionally, operators should follow proper stacking techniques to prevent instability and ensure the safe stacking of goods.

HCO Innovations can provide comprehensive warehouse layout evaluations, ensuring efficient storage and optimal utilization of warehouse space. Our experts can assess your current stacking methods and recommend improvements for maximizing safety and efficiency.

5. Awareness of Surroundings

Forklift operators should always be aware of their surroundings, continuously scanning for pedestrians, narrow aisles, blind spots, and potential obstructions. Maintaining clear visibility by using mirrors, lights, and other visibility aids is essential for accident prevention.

HCO Innovations can conduct safety assessments of your warehouse, identifying potential blind spots and areas of concern. Our team can provide recommendations for improving visibility and implementing additional safety measures to reduce the risk of accidents.

6. Regular Training and Review

Safe working practices should be reinforced through regular training and review sessions. It is important to stay updated on the latest safety guidelines and regulations pertinent to forklift operations. Conducting periodic refresher training for forklift operators helps to ensure ongoing compliance and awareness.

As a leading management consulting firm, HCO Innovations can provide continuous support and training for your warehouse operations. We can assist in conducting regular safety audits and providing refresher training to ensure your forklift operators are well-prepared.

In conclusion, implementing safe working practices for warehouse forklift operators is crucial for the well-being of employees, minimizing property damage, and maintaining compliance. HCO Innovations offers comprehensive services in warehouse optimization and forklift fleet management, allowing you to achieve significant cost reductions and operational efficiency. Contact us today at HCO Innovations to learn how we can help you optimize your warehouse operations and reduce material handling costs.