When it comes to running a successful warehouse or distribution center, optimizing your forklift fleet is key. Having an efficient and well-managed fleet not only ensures smooth operations but also helps reduce costs and improve productivity. In this article, we will explore some strategies to optimize your forklift fleet for maximum efficiency.

Regular Maintenance and Inspections

One of the most important aspects of optimizing your forklift fleet is to prioritize regular maintenance and inspections. By keeping your forklifts in top condition, you can prevent breakdowns and ensure that they operate at their full potential.

Schedule routine inspections and maintenance checks to identify any potential issues before they escalate. This includes checking the tires, brakes, forks, hydraulic system, and other critical components. Regularly lubricate moving parts and replace worn-out or damaged components promptly. Additionally, ensure that your forklifts are properly calibrated and aligned for optimal performance.

By investing in proactive maintenance practices, you can minimize downtime and avoid costly repairs. It also helps extend the lifespan of your forklifts, saving you money in the long run.

Operator Training and Safety

Another key factor in optimizing your forklift fleet is providing comprehensive operator training and enforcing strict safety protocols. Well-trained operators are more efficient and less likely to cause accidents or damage to the forklifts or inventory.

Ensure that all operators receive proper training on forklift operation, safety guidelines, and best practices. This includes teaching them how to handle different loads, navigate confined spaces, and perform routine inspections. Regularly conduct refresher training sessions to reinforce good habits and update operators on any new safety protocols.

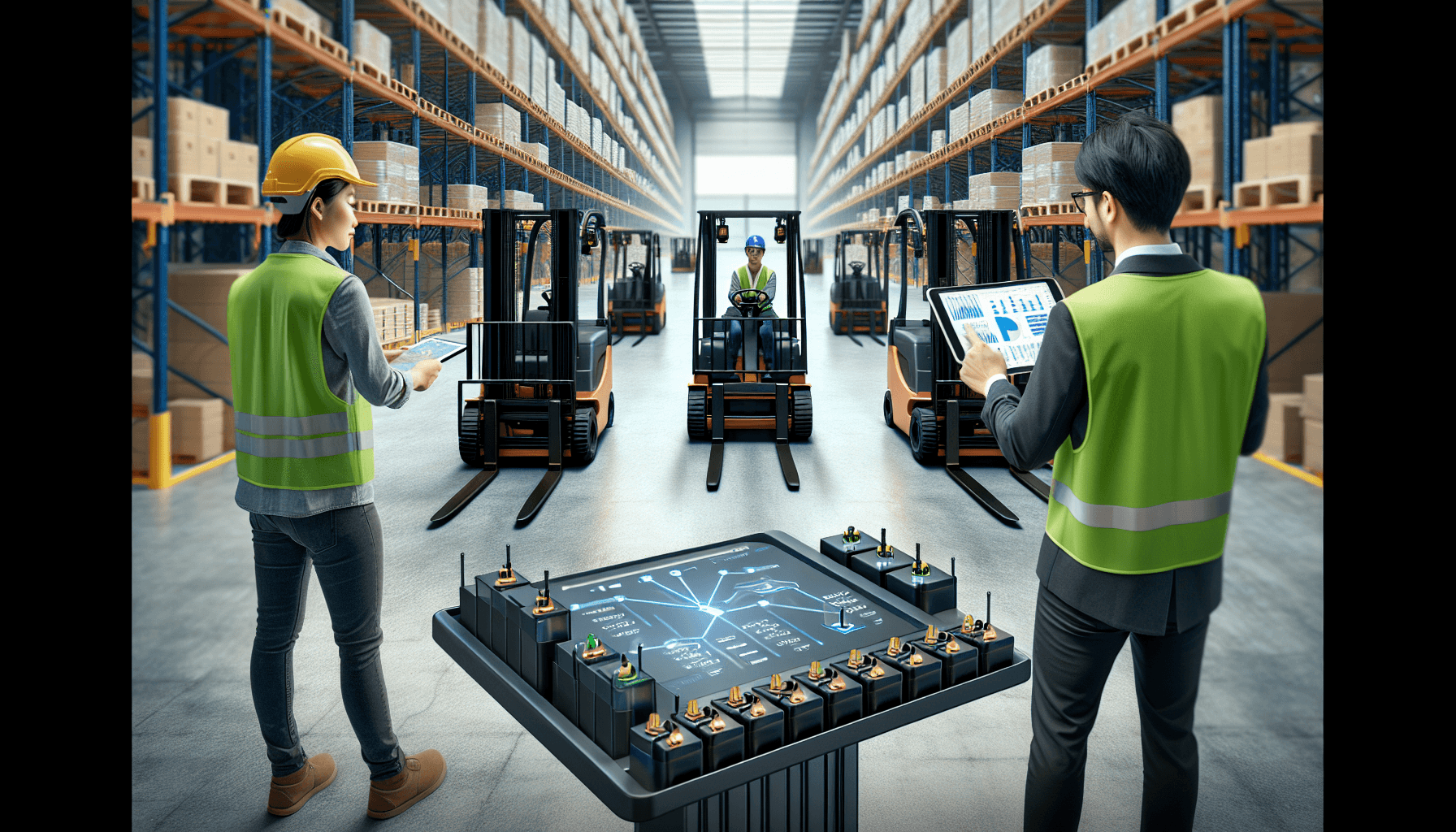

Furthermore, encourage a safety-first culture within your organization. Emphasize the importance of wearing seat belts, using safety equipment such as helmets and reflective vests, and following speed limits. Implement a reporting system for operators to report any safety concerns or near-misses, allowing you to address potential issues promptly.

By prioritizing operator training and safety, you can minimize accidents, reduce equipment damage, and improve overall fleet efficiency.

Data-Driven Fleet Management

Utilizing data and technology is crucial when optimizing your forklift fleet. Implementing a fleet management system allows you to track and analyze key performance metrics, identify areas for improvement, and make data-driven decisions to enhance efficiency.

A fleet management system can provide insights into forklift utilization, fuel consumption, maintenance schedules, and operator performance. This information allows you to identify any inefficiencies, such as underutilized forklifts or operators who may require additional training.

By monitoring data trends, you can identify patterns or anomalies that may suggest potential issues with specific forklifts or operators. Addressing these issues promptly can prevent downtime and keep your fleet running smoothly.

Additionally, consider integrating telematics technology into your forklifts. Telematics systems can track factors such as speed, distance traveled, and load weights, providing real-time data to help optimize operations. This data can assist in identifying areas where productivity can be improved or where further training may be needed.

To further enhance data-driven fleet optimization, consider partnering with a reputable forklift fleet management provider. They can provide comprehensive solutions tailored to your specific needs, leveraging their expertise and technology to help you achieve maximum efficiency.

Proactive Replacement and Upgrades

As forklifts age, their efficiency and performance may decline. To maintain optimal fleet efficiency, it’s essential to proactively evaluate your forklifts and consider replacement or upgrades when necessary.

Analyze the cost and frequency of repairs, as well as the overall productivity of older forklift models. If repairs become increasingly frequent or if newer models offer significant efficiency improvements, it may be time to retire older forklifts and invest in newer, more advanced models.

Upgrading to newer forklift models can offer benefits such as improved fuel efficiency, advanced safety features, and enhanced functionality. These upgrades can contribute to increased productivity and lower operating costs in the long term.

When considering replacement or upgrades, don’t forget to explore financing options or trade-in programs offered by forklift manufacturers or dealers. They can help make the transition more cost-effective and streamline the process.

Conclusion

Optimizing your forklift fleet for maximum efficiency is crucial for warehouse and distribution center operations. By prioritizing regular maintenance, providing comprehensive operator training, leveraging data-driven fleet management systems, and proactively replacing or upgrading older forklift models, you can enhance productivity, reduce costs, and improve overall operational efficiency.

For more information on how to optimize your forklift fleet management, visit HCO Innovations. They offer industry-leading solutions to help streamline your operations and maximize fleet efficiency.

Why is it important to optimize my forklift fleet?

Optimizing your forklift fleet is essential for maximizing efficiency and productivity in your warehouse or distribution center. By implementing strategies to optimize your fleet, you can reduce operating costs, improve safety, enhance overall performance, and streamline your material handling operations.

How can I determine if my forklift fleet needs optimization?

You can assess the need for forklift fleet optimization by evaluating various factors such as fleet utilization, maintenance costs, fuel efficiency, operator productivity, and safety records. Conducting a comprehensive fleet analysis can help identify areas for improvement and guide your optimization efforts.

What are some common optimization techniques for forklift fleets?

There are several techniques you can employ to optimize your forklift fleet, including regular maintenance and inspections, implementing fleet management software, conducting operator training programs, right-sizing your fleet, implementing battery management systems, and utilizing data analytics to track and measure performance.

How can fleet management software help optimize my forklift fleet?

Fleet management software provides real-time visibility into your forklift fleet's performance, allowing you to monitor factors like usage, maintenance schedules, fuel consumption, and operator behavior. It can help you identify inefficiencies, schedule preventive maintenance, optimize fleet utilization, and make data-driven decisions for continuous improvement.

What are the benefits of right-sizing my forklift fleet?

Right-sizing your forklift fleet involves determining the optimal number and types of forklifts needed to meet your operational requirements. By matching the fleet size and specifications to the workload, you can reduce idle time, minimize maintenance costs, optimize operator productivity, and improve overall efficiency.

How can I improve forklift operator productivity?

To enhance forklift operator productivity, you can provide comprehensive training programs that focus on safe operating practices, efficient material handling techniques, and proper equipment utilization. Regular performance evaluations, ongoing skill development, and incentivizing productivity can also contribute to improved operator efficiency.

What are the key safety considerations for optimizing a forklift fleet?

When optimizing a forklift fleet, safety should be a top priority. Important safety considerations include conducting regular equipment inspections, enforcing operator training and certification, implementing safety protocols and policies, promoting a culture of safety awareness, and ensuring compliance with relevant regulations and standards.

Can optimizing my forklift fleet help reduce operating costs?

Yes, optimizing your forklift fleet can lead to significant cost savings. By improving fleet utilization, minimizing maintenance expenses, increasing fuel efficiency, and reducing the risk of accidents and damage, you can lower your overall operating costs and improve your bottom line.

How often should I review and reassess my forklift fleet optimization strategies?

Forklift fleet optimization is an ongoing process. It is recommended to regularly review and reassess your strategies, at least annually, to ensure they align with your evolving operational needs, industry trends, technological advancements, and regulatory requirements.

When it comes to a well-functioning warehouse, optimizing the layout is crucial for enhancing forklift performance. A poorly designed layout can lead to inefficiencies, increased operational costs, and even safety hazards. At HCO Innovations, we understand the importance of a well-planned warehouse layout, which is why we specialize in providing comprehensive warehouse optimization solutions.

The Importance of Warehouse Layout Optimization

The layout of your warehouse plays a significant role in the overall efficiency of your operations. A well-optimized layout can improve productivity, reduce material handling costs, and enhance safety. Here are some key reasons why warehouse layout optimization is essential:

- Maximizing Space: By analyzing the available space and understanding your specific needs, our experts can help you make the most of the warehouse area. This includes strategically positioning storage racks, workstations, and equipment to ensure efficient movement and easy access.

- Efficient Workflow: A well-designed layout creates clear pathways and designated areas, facilitating the smooth flow of goods and minimizing congestion. With optimized workflow patterns, forklift drivers can navigate the warehouse easily, leading to faster and more efficient operations.

- Improved Productivity: An optimized layout reduces unnecessary movement and travel time for both forklift operators and warehouse personnel. This allows them to focus on their tasks and complete them in a more timely manner, enhancing overall productivity.

- Enhanced Safety: Safety is a top priority in any warehouse environment. With an optimized layout, potential hazards can be identified and mitigated, ensuring the safety of your employees and equipment. This includes proper positioning of storage racks, designated pedestrian walkways, and clear signage for improved visibility.

- Scalability and Adaptability: As your business grows or evolves, so too should your warehouse layout. An optimized layout is designed to accommodate future changes, allowing for easier expansion or reconfiguration of your warehouse while minimizing disruptions to operations.

HCO Innovations' Approach to Warehouse Layout Evaluation

At HCO Innovations, we take a holistic approach to warehouse layout evaluation. Our team of experts conducts thorough assessments to understand your current layout, operational procedures, and specific needs. Using advanced cost-tracking software and data analysis, we identify areas for improvement and develop customized solutions.

Our warehouse layout evaluation process includes:

- Data Collection: We gather detailed information about your warehouse, including floor plans, dimensions, equipment specifications, and existing workflow processes.

- Analysis: Our experts assess the collected data to identify bottlenecks, inefficiencies, and areas that can be optimized to enhance overall performance.

- Design and Simulation: Using advanced software, we create 2D and 3D simulations of the optimized layout, allowing you to visualize the proposed changes and assess their impact on operations.

- Implementation: Once the optimized layout is approved, we provide support and guidance throughout the implementation phase. Our team works closely with your staff to ensure a smooth transition and minimal disruption to daily operations.

- Continuous Improvement: We monitor the performance of the new layout, making adjustments as needed to further enhance efficiency and address any emerging challenges.

Partnering with HCO Innovations for Warehouse Layout Optimization

When you partner with HCO Innovations for warehouse layout optimization, you can expect a range of benefits. Our tailored solutions are designed to deliver exceptional return on investment and help you achieve significant cost reductions and operational efficiency. Here's what sets us apart:

- Experience and Expertise: With over a decade of experience in warehouse optimization, our team has the knowledge and expertise to tackle even the most complex challenges. We have worked with clients across various industries, including distribution, manufacturing, and food processing.

- Collaborative Approach: We work closely with our clients, taking a "boots on the ground" approach to understand their unique needs and challenges. We believe in open communication and collaboration to develop tailored solutions that align with your goals.

- Advanced Technology: HCO Innovations leverages advanced cost-tracking software and simulation tools to analyze data, create optimized layouts, and measure the impact of proposed changes. This allows us to provide data-driven insights and solutions that drive tangible results.

- Comprehensive Services: We offer a range of services beyond warehouse layout evaluation, including safety assessments, turnkey maintenance solutions, and ongoing support. Our goal is to provide comprehensive solutions that address all aspects of warehouse optimization and forklift fleet management.

- Proven Track Record: Our tailored solutions have consistently delivered exceptional results for our clients. We have helped organizations achieve significant cost savings, improve productivity, enhance safety, and streamline operations.

At HCO Innovations, we are committed to optimizing warehouse operations and reducing material handling costs for our clients. With our expertise and collaborative approach, we can help transform your warehouse layout and drive significant improvements in forklift performance. Contact us today at HCO Innovations to learn more about how we can help your business thrive.