Forklifts are a critical part of warehouse operations, enabling the safe and efficient movement of goods. However, without proper adherence to forklift safety guidelines, accidents can happen, posing a risk to both employees and equipment. In this article, we will discuss some of the common forklift safety violations that occur in warehouse settings and provide guidance on how to address them.

1. Failure to Provide Adequate Training and Certification

One of the most common forklift safety violations is the failure to provide employees with proper training and certification. Operating a forklift requires specialized skills and knowledge to ensure the safe handling of materials. Without adequate training, forklift operators may not be aware of important safety measures or may not be proficient in maneuvering the equipment.

To address this violation, it is crucial for warehouse managers to prioritize comprehensive forklift training programs. This includes classroom instruction on safety protocols, hands-on practice sessions, and evaluations to assess an operator’s proficiency. Additionally, it is essential to ensure that all forklift operators hold valid certifications, demonstrating their ability to operate the equipment safely.

At HCO Innovations, we understand the importance of forklift operator training and offer comprehensive training programs tailored to warehouse operations. With our warehouse safety evaluation, we can assess your current training protocols and develop customized training solutions to address any gaps and ensure compliance with safety regulations.

2. Lack of Regular Forklift Inspections and Maintenance

Another common forklift safety violation is the neglect of regular inspections and maintenance. Forklifts are subjected to daily wear and tear, and any malfunction or defects could lead to accidents. Failing to conduct routine inspections and maintenance increases the risk of equipment failure during operational use.

To address this violation, warehouse managers should implement a robust inspection and maintenance program for all forklifts. This includes daily pre-shift inspections, where operators check for any visible damage or malfunctions before starting work. Regular maintenance schedules should also be in place, with qualified technicians conducting thorough inspections, servicing, and repairs as needed.

At HCO Innovations, we provide warehouse optimization solutions, including maintenance management systems, that can help streamline the inspection and maintenance process for forklifts. Our systems allow you to schedule and track inspections, automate maintenance tasks, and generate reports to ensure compliance with safety regulations.

3. Ignoring Load Capacity Limits and Stability Concerns

Ignoring load capacity limits and stability concerns is another significant forklift safety violation. Overloading a forklift or improperly distributing the load can result in tip-overs, causing serious injuries to operators and potential damage to the goods being transported. It is crucial to follow load capacity guidelines and ensure proper load distribution for the safe operation of forklifts.

To address this violation, warehouse managers should emphasize the importance of adhering to load capacity limits and teach operators how to properly secure and distribute loads on the forklift. Operators should also be trained on how to assess load stability before moving the forklift and avoid sudden movements or sharp turns that may compromise the stability of the load.

At HCO Innovations, we offer warehouse optimization solutions that can help improve load management and enhance forklift stability. Our advanced technology solutions provide real-time load monitoring, offering valuable insights into load distribution and ensuring operators stay within safe load capacity limits.

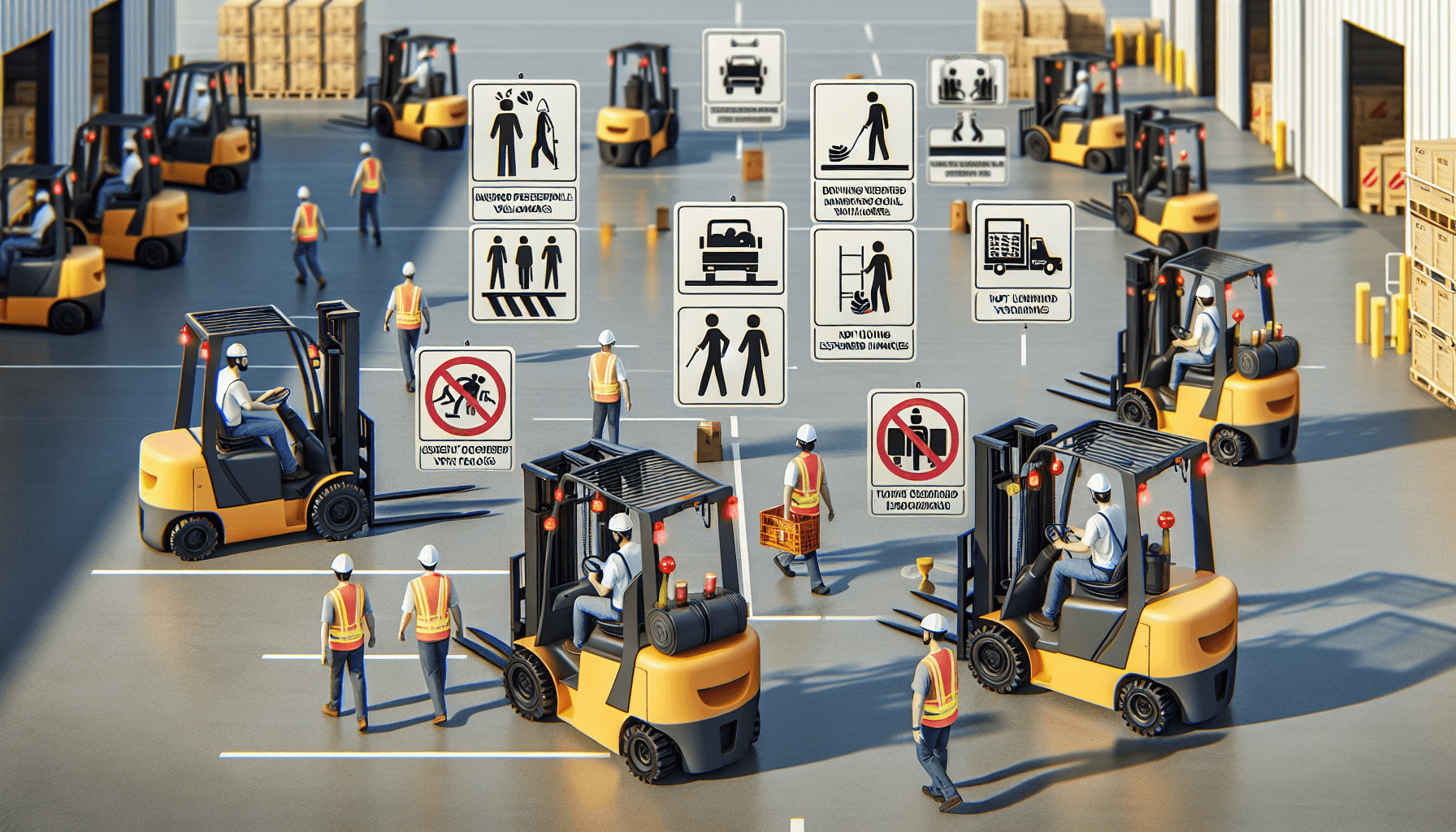

4. Failure to Provide Adequate Traffic Management

Inadequate traffic management is another common forklift safety violation that can lead to accidents and near misses within a warehouse. With multiple forklifts and pedestrians moving in close proximity, it is essential to establish clear traffic routes and implement effective signage and markings to prevent collisions.

To address this violation, warehouse managers should conduct a thorough assessment of their traffic management strategy. This includes clearly marked pedestrian walkways, designated forklift lanes, and the use of mirrors and warning signs to alert both forklift operators and pedestrians to potential hazards. Regular training sessions should also be held to educate employees on safe traffic practices and the importance of staying alert in high-traffic areas.

At HCO Innovations, we specialize in warehouse optimization solutions, including traffic management systems. Our expertise in designing efficient traffic flow patterns and implementing advanced safety measures can help minimize the risk of collisions and enhance overall warehouse safety.

Conclusion

Addressing forklift safety violations is crucial to maintaining a safe and productive warehouse environment. By providing adequate training and certification, conducting regular inspections and maintenance, adhering to load capacity limits, and implementing effective traffic management strategies, warehouse managers can mitigate the risks associated with forklift operations.

At HCO Innovations, we are committed to helping warehouse operations optimize safety, productivity, and efficiency. With our comprehensive warehouse optimization solutions, including training programs, maintenance management systems, and traffic management systems, we can assist you in addressing forklift safety violations and creating a safer working environment for your employees.

What are the most common forklift safety violations?

The most common forklift safety violations include speeding, improper turning, failing to yield the right of way, unauthorized personnel operating forklifts, and inadequate training.

How can I address the issue of speeding with forklifts?

To address the issue of speeding with forklifts, set and enforce speed limits, install speed limit signs, provide refresher training on safe driving practices, and implement consequences for violating the speed limits.

What should I do if I encounter an unauthorized person operating a forklift?

If you encounter an unauthorized person operating a forklift, immediately notify a supervisor or manager. It is crucial to report such instances as it poses a significant safety risk to both the individual and others in the vicinity.

How can I ensure proper turning with forklifts?

To ensure proper turning with forklifts, always slow down and sound the horn when approaching corners or intersections. Keep the load low and stable, ensure enough space for turning, and use the correct turning technique as specified in the forklift's operating manual.

What can be done to ensure forklift operators yield the right of way?

To ensure forklift operators yield the right of way, provide clear guidelines on right-of-way rules and enforce them strictly. Educate all forklift operators about the consequences of not yielding the right of way and encourage a safety-focused work culture.

How can I address inadequate training regarding forklift safety?

To address inadequate training regarding forklift safety, ensure that all forklift operators undergo comprehensive training before operating the equipment. Regularly evaluate and update the training program to align with the latest safety standards. Encourage continuous learning and provide refresher training sessions as needed.

What are the consequences of forklift safety violations?

The consequences of forklift safety violations can vary depending on the severity of the violation and the company's policies. They can range from verbal warnings and additional training to suspension, termination, or legal repercussions. It is important to take safety violations seriously to protect the well-being of all employees and maintain a safe work environment.

Improving Warehouse Efficiency: Tips and Best Practices to Optimize Operations

Efficiency is a crucial aspect of any warehouse operation. When a warehouse is running efficiently, it can greatly impact the overall productivity and profitability of a business. From optimizing the layout to managing the forklift fleet, there are several steps that can be taken to streamline operations and improve efficiency. In this article, we will explore some tips and best practices to help warehouse owners and managers optimize their operations and achieve better results.

1. Evaluate and Optimize Warehouse Layout

One of the first steps in improving warehouse efficiency is to evaluate and optimize the warehouse layout. A well-planned layout can significantly reduce travel time, minimize congestion, and improve overall productivity. Consider the following factors when optimizing the warehouse layout:

- Product Flow: Analyze the flow of products from receiving to shipping. Ensure that there is a logical and efficient pathway for goods to move through the warehouse.

- Zoning: Divide the warehouse into zones to organize products based on their characteristics, such as size, popularity, or storage requirements. This allows for easier retrieval and improves picking and packing operations.

- Location Assignment: Assign specific locations for each item in the warehouse. This not only helps in finding products faster but also ensures better inventory management and accuracy.

- Optimal Space Utilization: Make the most of the available space by using vertical storage systems, mezzanines, and rack configurations. This increases storage capacity and frees up valuable floor space.

To assist with warehouse layout evaluation and optimization, consider partnering with an experienced management consulting firm like HCO Innovations. They specialize in warehouse optimization and offer comprehensive services to help businesses maximize their storage capabilities and improve operational efficiency.

2. Implement Efficient Inventory Management Systems

Effective inventory management is crucial for warehouse efficiency. It involves accurately tracking inventory levels, optimizing stock replenishment, and minimizing stockouts. The following practices can help improve inventory management:

- Inventory Tracking: Utilize a robust inventory management system to track inventory levels in real-time. This helps in avoiding stockouts, reducing excess inventory, and improving order fulfillment.

- ABC Analysis: Prioritize products based on their sales volume, value, and importance. Classify products into categories (A, B, and C) and allocate storage space accordingly. This ensures that high-demand products are easily accessible.

- Just-in-Time (JIT) Inventory: Implement JIT inventory management to reduce carrying costs and minimize waste. This approach ensures that inventory arrives just in time for production or order fulfillment.

- Regular Cycle Counts: Conduct frequent cycle counts to ensure inventory accuracy. Regular checks help identify discrepancies, theft, or product obsolescence, enabling timely corrective actions.

3. Optimize Forklift Fleet Management

Forklifts play a critical role in warehouse operations, and their effective management can greatly impact efficiency. Here are some tips to optimize forklift fleet management:

- Maintenance and Repairs: Implement a proactive maintenance program to keep forklifts in optimal condition. Regular servicing, inspections, and repairs can help prevent breakdowns and extend equipment lifespan.

- Operator Training: Ensure that forklift operators are properly trained and certified. Proper training not only improves safety but also enhances productivity and reduces the risk of accidents.

- Optimal Utilization: Analyze forklift usage patterns to determine optimal fleet size and deployment. This helps in avoiding underutilization or overburdening of forklifts, ultimately saving costs.

- Energy Efficiency: Consider using electric forklifts or exploring alternative energy sources to reduce fuel consumption and emissions. This not only benefits the environment but also lowers operational costs.

To ensure efficient forklift fleet management and achieve significant cost reductions, businesses can leverage the expertise of management consulting firms like HCO Innovations. They specialize in forklift fleet optimization and provide turnkey maintenance solutions to help businesses save money and improve overall operations.

4. Embrace Technology and Automation

Advancements in technology have revolutionized the warehousing industry. By embracing technological solutions, warehouses can enhance productivity and efficiency. Consider the following technology-driven practices:

- Warehouse Management Systems (WMS): Implement a WMS to streamline various processes, including order fulfillment, picking, packing, and inventory management. WMS optimizes resource utilization and improves overall accuracy.

- Barcode Scanning: Use barcode scanning technology to track and manage inventory. This reduces errors, improves picking accuracy, and speeds up operations.

- Automated Guided Vehicles (AGVs): Introduce AGVs for automated material handling within the warehouse. AGVs can efficiently transport goods, reducing labor costs and improving safety.

- Cloud-Based Systems: Adopt cloud-based systems for real-time data access and collaboration. This facilitates seamless communication and enables better decision-making.

5. Regularly Review and Improve Processes

Continuous improvement is essential to maintain warehouse efficiency. Regularly review processes and identify areas for improvement. Engage warehouse staff to provide valuable insights and implement their suggestions whenever possible. Some best practices for process improvement include:

- Data Analysis: Analyze data generated by various systems, such as WMS and inventory management systems, to identify bottlenecks, inefficiencies, or opportunities for improvement.

- Workflow Optimization: Streamline workflows to eliminate unnecessary steps, reduce handoffs, and improve overall efficiency.

- Collaboration: Encourage collaboration and effective communication between different teams within the warehouse. This promotes smoother operations and helps address challenges proactively.

- Employee Engagement: Invest in employee training and development to enhance their skills and knowledge. Engaged employees are more likely to contribute positively to the warehouse's productivity.

By following these tips and best practices, warehouse owners and managers can optimize their operations, reduce costs, and improve profitability. Remember, efficiency is not a one-time goal but an ongoing process that requires continuous evaluation and improvement.

If your business needs assistance with warehouse optimization or forklift fleet management, feel free to reach out to HCO Innovations. Their expertise and tailored solutions can help you achieve significant cost reductions and operational efficiency.