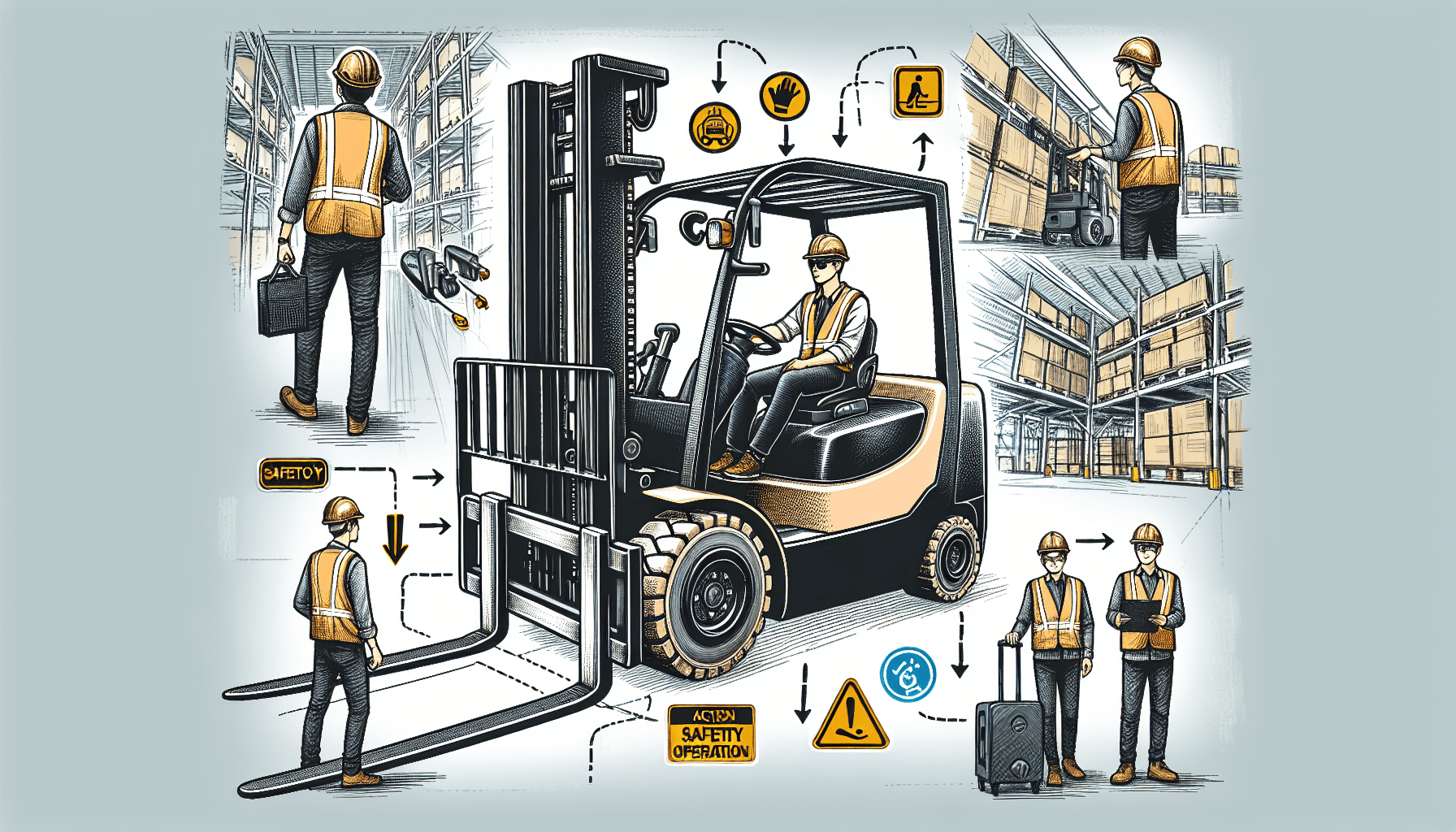

Forklifts are an essential piece of equipment in warehouse operations. They are used for lifting and transporting heavy loads, making them a valuable asset in optimizing warehouse productivity and efficiency. However, with the power and capabilities of forklifts also come certain risks and hazards. Accidents involving forklifts can lead to severe injuries and damage to property, which is why implementing proper safety measures is crucial.

The Importance of Forklift Attachments

One effective way to enhance forklift safety and prevent accidents is through the use of forklift attachments. These attachments are specialized tools that can be added to a forklift to extend its functionality and increase its versatility. By using the right attachments, warehouse operators can minimize risks and create a safer working environment for their employees.

There are several types of forklift attachments available, each designed for specific purposes. Let’s explore some of the most common attachments and how they contribute to accident prevention:

1. Fork Positioners

Fork positioners are attachments that allow the forklift operator to adjust the distance between the forks to accommodate loads of different sizes. This eliminates the need for manual adjustments and reduces the risk of using the wrong-sized forks, which can lead to load instability and tip-overs. Fork positioners enhance productivity by enabling faster load handling while improving safety by promoting proper load support.

2. Side Shifters

Side shifters are attachments that enable the horizontal movement of the forks to the left or right without repositioning the entire forklift. This feature is especially useful when aligning the forks with pallets or load openings, reducing the need for manual adjustments. By using side shifters, operators can minimize the risk of accidentally hitting racks or other obstacles, preventing accidents and reducing potential damage to both the forklift and the warehouse infrastructure.

3. Carton Clamps

Carton clamps are attachments designed for handling fragile or irregularly shaped loads, such as cartons or boxes. These clamps secure the load in place, preventing shifting or crushing during transportation. By securely gripping the load, carton clamps reduce the risk of load damage, improving safety and minimizing product loss. They also allow for efficient handling of multiple cartons simultaneously, increasing productivity within the warehouse.

4. Forklift Safety Cages

Safety cages, also known as man cages, are attachments that enable the safe lifting of personnel to perform tasks at elevated heights. These cages provide a platform with guardrails and secure latches to ensure the safety of workers working at heights. By using safety cages, companies can comply with safety regulations and prevent accidents related to falls or improper use of makeshift platforms.

5. Forklift Extensions

Forklift extensions are attachments that extend the length of the forklift forks, allowing for the handling of longer loads. By using extensions, operators can maintain load stability and prevent accidents caused by overhanging loads. Forklift extensions are particularly useful when handling materials such as lumber, pipes, or metal sheets, enabling safe and efficient transportation within the warehouse.

By implementing these and other forklift attachments, warehouse operators can significantly enhance safety within their facilities. However, it’s important to note that proper training and regular maintenance are also vital in maintaining a safe warehouse environment. Operators should receive training on the proper use of forklift attachments and be familiar with the specific safety guidelines provided by the attachment manufacturers.

If you’re unsure about the safety of your warehouse operations or want to evaluate your current safety measures, HCO Innovations offers a comprehensive warehouse safety evaluation. Our experts can assess your facility, identify potential hazards, and provide recommendations for enhancing safety, productivity, and efficiency. Don’t wait for an accident to happen – take proactive steps to create a safer warehouse environment today.