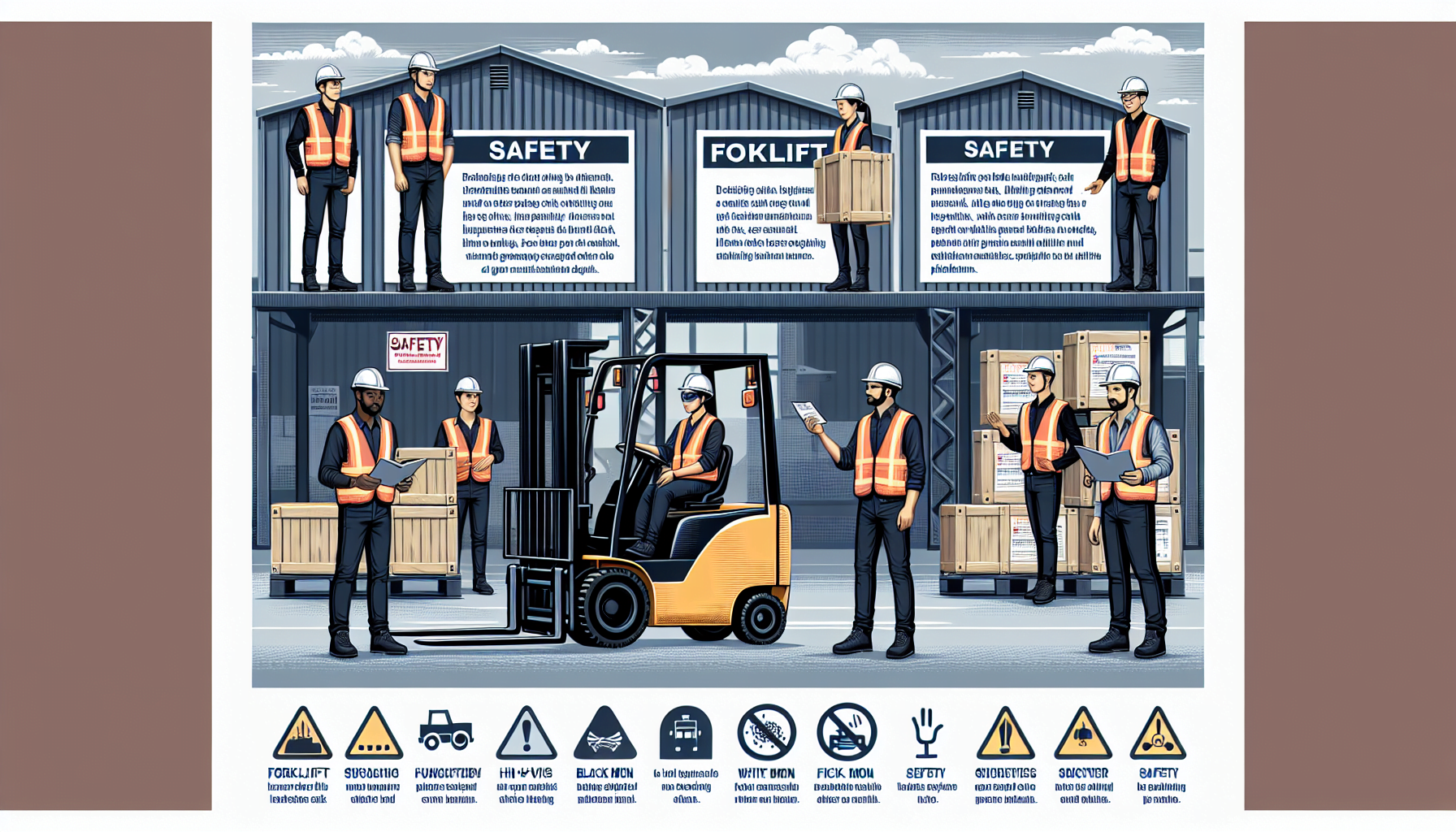

Forklifts play a crucial role in warehouse operations, allowing for efficient movement of heavy loads and streamlining various tasks. However, they can also pose significant safety risks if not managed properly. This is especially true in temporary warehouses where factors like limited space, changing layouts, and increased activity can increase the potential for accidents. In this article, we will discuss some essential tips for effectively managing forklift safety in temporary warehouses.

1. Implement Comprehensive Training Programs

One of the first steps in ensuring forklift safety is to provide comprehensive training programs for all forklift operators. This training should cover not only the basic operation of the forklift but also specific safety guidelines for working in temporary warehouses. Operators should be trained on safe driving techniques, proper load handling, and awareness of their surroundings to minimize the risk of accidents. Regular refresher courses and evaluations should also be conducted to ensure that operators are up to date on the latest safety practices.

2. Conduct Regular Inspections and Maintenance

Regular inspections and maintenance of forklifts are crucial for ensuring their safe operation. In temporary warehouses where forklifts may be utilized more frequently, it is even more important to have a structured maintenance schedule in place. This includes checking for any signs of wear and tear, inspecting brakes and tires, and ensuring that all safety features, such as lights and horns, are in working order. Any necessary repairs or replacements should be addressed promptly to avoid potential hazards.

3. Optimize Warehouse Layout and Traffic Flow

The layout and traffic flow of a temporary warehouse can greatly impact forklift safety. It is essential to plan the warehouse layout in a way that minimizes congestion and provides ample space for forklifts to maneuver safely. Clearly marked pathways and designated areas for loading and unloading can help prevent accidents and ensure smooth operations. Additionally, implementing traffic control measures such as speed limits and signage can further enhance safety and reduce the risk of collisions.

4. Provide Adequate Lighting and Signage

Proper lighting is essential in temporary warehouses to ensure optimal visibility and minimize the risk of accidents. Well-lit areas can help forklift operators clearly see potential obstacles and hazards, while also enabling them to read signs and labels on equipment. Adequate signage should also be placed throughout the warehouse, indicating areas of caution, speed limits, and pedestrian crossings. This will help create a safer working environment and promote better awareness among employees.

5. Encourage Communication and Awareness

Good communication and awareness among warehouse staff are vital for ensuring forklift safety. Encourage employees to report any potential hazard or unsafe practices promptly. Regular safety meetings and toolbox talks can also serve as effective platforms for discussing safety concerns, sharing best practices, and addressing any specific issues related to forklift operations in temporary warehouses. Creating a culture of safety awareness and accountability will contribute to a safer working environment for everyone.

6. Regularly Review and Update Safety Policies

Warehouse operations are dynamic, and safety policies need to be regularly reviewed and updated to align with any changes in processes or regulations. Temporary warehouses, in particular, may experience frequent layout changes or modifications in inventory storage, which can impact forklift safety. By regularly reviewing and updating safety policies, organizations can adapt to new challenges and implement necessary changes to ensure continued safety and compliance.

Conclusion

Effective management of forklift safety in temporary warehouses requires a proactive approach and a focus on comprehensive training, regular inspections, optimized layout, adequate lighting, and clear communication. By implementing these tips, warehouse operators can create a safer working environment and reduce the risk of accidents and injuries. For a comprehensive analysis of your warehouse safety practices, consider utilizing HCO Innovations’ professional warehouse safety evaluation services to identify any potential areas for improvement. Remember, prioritizing forklift safety is essential for the well-being of your employees and the overall success of your warehouse operations.