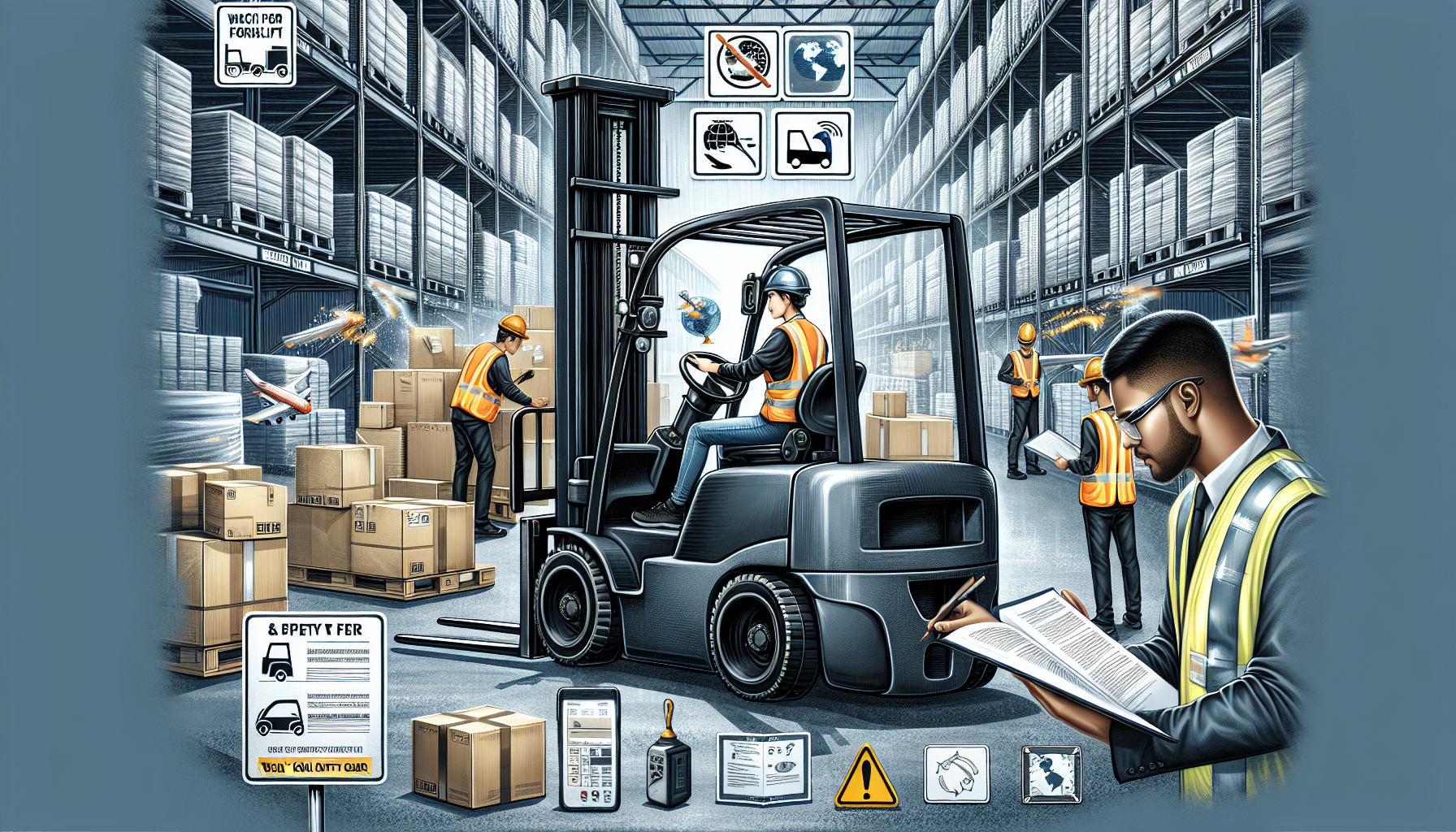

In today’s fast-paced supply chain industry, efficient and safe warehouse operations are crucial for the success of any business. One of the key elements in achieving warehouse optimization is forklift safety. Forklifts play a significant role in material handling and can enhance productivity and efficiency when used properly. However, improper use of forklifts can lead to accidents, injuries, and damage to goods and equipment.

The Importance of Forklift Safety

Forklifts are powerful and versatile machines used for lifting and moving heavy loads in warehouses and distribution centers. They are designed to make tasks easier and more efficient, but they can also be hazardous if not operated safely. Forklift accidents can cause severe injuries, including crushed limbs, falls from elevated platforms, and collisions with pedestrians or other vehicles.

Ensuring proper forklift safety is crucial for several reasons:

- Protecting Employees: The safety and well-being of warehouse employees should be the top priority for any business. By implementing and enforcing forklift safety protocols, employers can significantly reduce the risk of accidents and injuries.

- Preventing Equipment and Property Damage: Forklift accidents can also result in damage to goods, equipment, and warehouse infrastructure. By promoting forklift safety practices, businesses can minimize the risk of costly damages and downtime.

- Complying with Regulations: Forklift operations are subject to specific safety regulations and standards set by organizations such as OSHA (Occupational Safety and Health Administration). Compliance with these regulations is not only essential for employee safety but also for avoiding legal issues and penalties.

- Enhancing Productivity: When forklifts are operated safely, they can significantly improve warehouse productivity. Well-trained forklift operators are more efficient, which leads to faster and smoother material handling operations.

Warehouse safety evaluations are vital for identifying potential hazards and implementing appropriate safety measures. Regular evaluations can help businesses identify areas for improvement and ensure ongoing compliance with safety regulations.

Best Practices for Forklift Safety

Implementing and enforcing forklift safety practices is essential for minimizing risks and maintaining a safe working environment. Here are some best practices to consider:

- Proper Training: All forklift operators should receive thorough training on safe operation, load handling, and maintenance procedures. Training programs should cover topics such as balance and stability, safe speeds, turning, and the use of safety devices.

- Regular Inspections: Forklifts should undergo regular inspections to ensure they are in good working condition. Inspections should include checks for brakes, tires, lights, steering, and other critical components.

- Safe Load Handling: Operators should be trained on how to properly load and unload materials to avoid overloading or unbalanced loads. Forklifts should only carry loads within their specified capacity.

- Clear Traffic Management: Implement clear traffic management plans to separate forklifts from pedestrians and other vehicles within the warehouse. Clear signage, designated paths, and barriers can help prevent accidents and collisions.

- Safe Speeds: Establish and enforce speed limits for forklifts within the warehouse. Encourage operators to drive at a safe and controlled speed, especially when turning or operating in congested areas.

- Proper Maintenance: Regular maintenance and servicing of forklifts are crucial for ensuring they are in optimal condition. This includes checking fluid levels, inspecting hydraulics, and addressing any mechanical issues promptly.

- Adherence to Safety Rules: Develop and enforce strict safety policies for forklift operations. This includes wearing proper PPE (Personal Protective Equipment), prohibiting use by unauthorized personnel, and reporting any accidents or incidents immediately.

By implementing these best practices and regularly reevaluating forklift safety within your warehouse, you can create a safer and more efficient working environment for your employees.

In conclusion, forklift safety is a critical component of warehouse optimization and supply chain management. Prioritizing proper forklift safety measures benefits both the well-being of employees and the overall productivity and efficiency of warehouse operations. By investing in training, regular inspections, and adherence to safety protocols, businesses can minimize accidents, prevent damage, and ensure compliance with regulations. Remember, safety should always be the number one priority in any warehouse environment.