In the fast-paced world of warehousing and logistics, safety should always be a top priority. Warehouse operations involve various types of equipment, including forklifts, which play a crucial role in material handling and movement. While forklifts are essential for improving efficiency and productivity in a warehouse, they can also pose significant risks if not operated or maintained properly. Forklift accidents can have a detrimental impact not only on the wellbeing of employees but also on customer relationships.

The Importance of Safety in Warehouse Operations

Before delving into the impact of forklift accidents on customer relationships, it is crucial to understand the importance of safety in warehouse operations. Warehouses are dynamic environments where multiple activities happen simultaneously. With workers, machinery, and inventory coming together, there is an inherent risk of accidents and injuries. Implementing proper safety measures, including comprehensive training programs, regular equipment maintenance, and efficient layout designs, is imperative to create a safe working environment.

Warehouse operators must prioritize safety to protect their employees, minimize downtime due to accidents, and mitigate potential financial losses. When safety protocols are in place and adhered to, warehouse operations can run smoothly, keeping workers safe and enabling efficient order fulfillment.

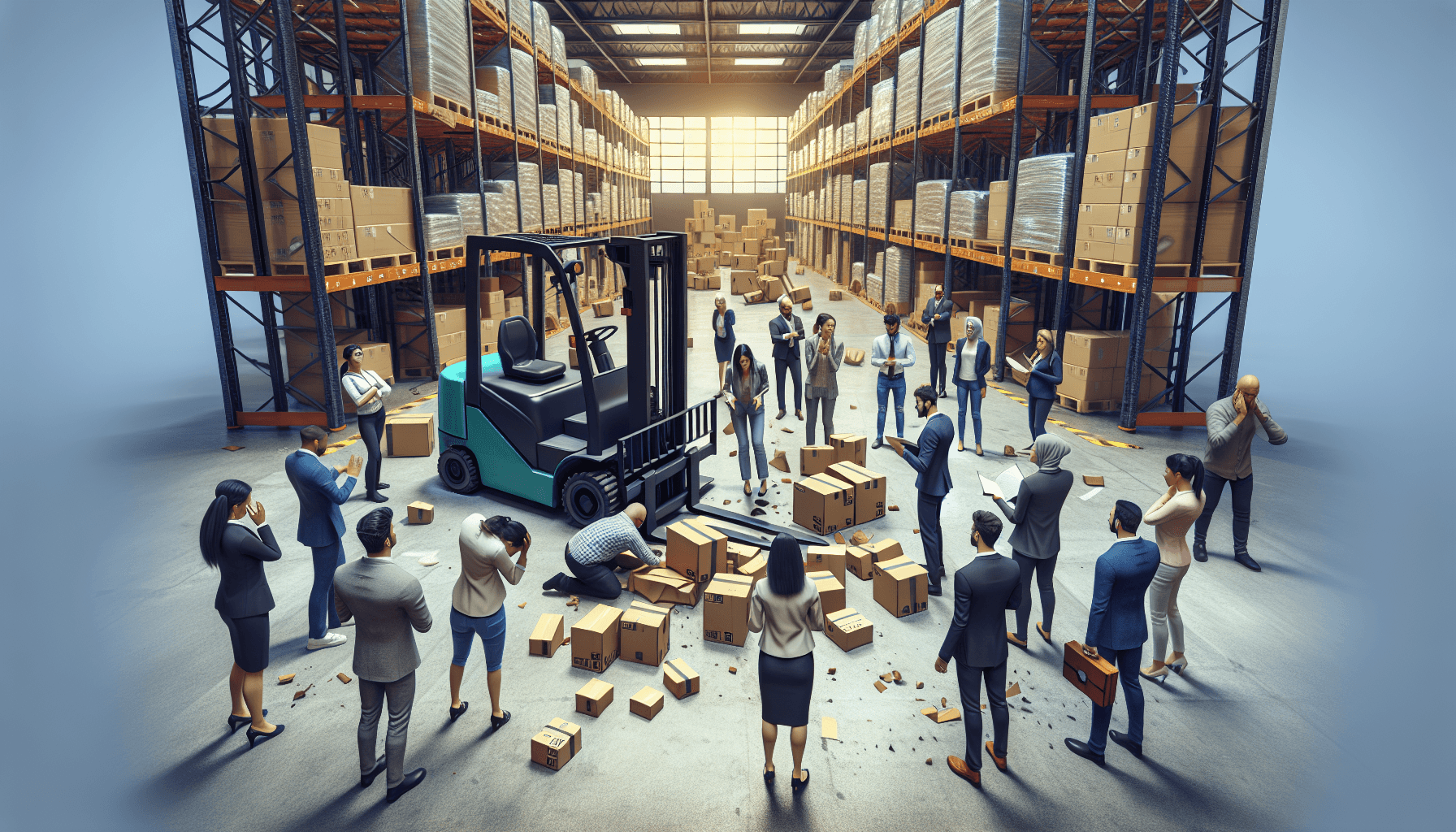

The Impact of Forklift Accidents

Despite the best safety efforts, forklift accidents can occur, leading to serious consequences. Forklifts are powerful and heavy machinery, capable of causing damage to both infrastructure and personnel. When an accident happens, several negative outcomes can arise, including:

- Employee injuries: The most immediate impact of a forklift accident is the potential injury to the operator or other workers in the vicinity. Injuries can range from minor cuts and bruises to severe fractures or even fatalities.

- Property damage: Forklift accidents can result in damage to the warehouse infrastructure, including racking systems, walls, or inventory. This can lead to costly repairs and replacement of damaged goods, affecting the overall profitability of the business.

- Decreased productivity: When an accident occurs, it disrupts the workflow within the warehouse. Investigations, medical interventions, and equipment repairs take valuable time and resources away from regular operations, leading to decreased productivity.

- Increased costs: Forklift accidents can have a significant financial impact on a warehouse operation. Costs can include medical expenses, increased insurance premiums, equipment repairs, and potential lawsuits. These additional costs can erode the profit margin and strain the company’s budget.

- Reputation damage: Another significant but often overlooked consequence of forklift accidents is the damage they can cause to a company’s reputation. News of accidents can spread quickly, impacting how potential customers perceive the warehouse’s safety practices. This can lead to a loss of trust and ultimately affect customer relationships.

Preserving Customer Relationships

Customer relationships are the lifeblood of any business, and maintaining trust and positive perception is crucial for long-term success. Forklift accidents can shake that trust and compromise customer relationships in several ways:

1. Delays in order fulfillment: Forklift accidents can disrupt normal warehouse operations, leading to delays in fulfilling customer orders. Late deliveries or prolonged lead times can frustrate customers and damage their perception of the company’s reliability.

2. Damaged goods: In accidents where inventory is damaged, customers may receive products that are compromised or defective. This not only leads to dissatisfaction but also raises concerns about the overall quality control and handling practices within the warehouse.

3. Communication breakdown: Following a forklift accident, warehouse operators may need to communicate with customers to inform them of any potential delays or issues. Failure to effectively communicate the situation can breed mistrust and further strain customer relationships.

4. Safety concerns: Customers value their own safety as well as the safety of those who handle their orders. If a warehouse has a reputation for frequent forklift accidents, customers may question whether their products are being handled with care, potentially leading them to seek alternative suppliers.

5. Loss of business: Ultimately, if a company’s reputation is significantly tarnished by forklift accidents, customers may choose to take their business elsewhere. Losing customers due to a lack of trust can be detrimental to the overall success and sustainability of a warehouse operation.

Given the potential negative impact of forklift accidents on customer relationships, it is imperative for warehouse operators to prioritize safety and implement proactive measures to prevent accidents from occurring in the first place.

By partnering with a trusted warehouse optimization solutions provider like HCO Innovations, warehouses can enhance safety, productivity, and efficiency within their operations. HCO Innovations offers warehouse safety evaluation services, including comprehensive assessments, tailored training programs, and advanced technology solutions to mitigate the risks associated with forklift accidents.

Click here to learn more about HCO Innovations’ warehouse safety evaluation services.

In conclusion, forklift accidents can have far-reaching consequences, especially when it comes to customer relationships. By prioritizing safety, implementing preventive measures, and partnering with experts like HCO Innovations, warehouses can minimize the risks associated with forklift accidents, protect their employees, and maintain strong customer relationships.

What are the common causes of forklift accidents?

Common causes of forklift accidents include operator error, lack of proper training, inadequate maintenance, poor visibility, and improper load handling.

How can forklift accidents affect customer relationships?

Forklift accidents can negatively impact customer relationships as they can lead to delays in product delivery, damaged goods, increased costs, and a loss of trust and confidence in the company's ability to provide safe and reliable service.

What steps can be taken to prevent forklift accidents?

To prevent forklift accidents, companies should ensure proper training and certification for all operators, conduct regular maintenance and inspections of forklifts, implement clear and well-marked pedestrian zones, provide proper safety equipment, promote a culture of safety awareness, and enforce strict adherence to safety policies and procedures.

Are there any legal consequences for forklift accidents?

Yes, there can be legal consequences for forklift accidents. Depending on the severity and circumstances of the accident, companies may face fines, penalties, and potential lawsuits. It is important for businesses to comply with forklift safety regulations to avoid legal liabilities.

How can a business repair customer relationships after a forklift accident?

After a forklift accident, businesses can repair customer relationships by taking responsibility for the incident, promptly addressing any damages or delays caused by the accident, providing open and transparent communication with affected customers, offering compensation or alternative solutions where appropriate, and implementing measures to prevent similar accidents from occurring in the future.

Can forklift accidents impact the reputation of a business?

Yes, forklift accidents can significantly impact the reputation of a business. Negative incidents involving forklift accidents can spread quickly through word-of-mouth or social media, leading to a tarnished brand image and potential loss of customers.

How can businesses improve forklift safety in their operations?

Businesses can improve forklift safety by prioritizing employee training and certification, promoting a safety culture, conducting regular safety audits, providing proper maintenance and inspection of forklifts, investing in safety technology such as warning systems or proximity sensors, and fostering open lines of communication for reporting and addressing safety concerns.

Are there any industry standards or regulations regarding forklift safety?

Yes, there are industry standards and regulations regarding forklift safety. These may include guidelines set by organizations such as OSHA (Occupational Safety and Health Administration) or specific regulations outlined by local or national governmental entities. It is important for businesses to stay informed and compliant with these standards in order to ensure the safety of their employees and customers.

The Role of Safety Training in Preventing Forklift Accidents

Welcome to HCO Innovations, your trusted partner in warehouse optimization and forklift fleet management. Here at HCO Innovations, we understand the importance of safety in warehouse operations, especially when it comes to preventing forklift accidents. In this article, we will explore the crucial role of safety training in reducing the risk of forklift accidents and ensuring the well-being of both employees and equipment.

The Importance of Safety Training

When it comes to operating a forklift, safety should always be the top priority. Forklifts are powerful, heavy machinery that require skill and expertise to operate safely. Without proper training, operators may unknowingly put themselves and others at risk. Safety training plays a fundamental role in preventing accidents, injuries, and even fatalities in the workplace.

At HCO Innovations, we believe that investing in safety training is a proactive measure that not only protects employees but also safeguards your business. Here are some key reasons why safety training is essential:

- Ensures compliance with regulations: Occupational Safety and Health Administration (OSHA) has specific requirements and guidelines for forklift operators. Safety training helps ensure that your business complies with these regulations, avoiding costly fines and penalties.

- Reduces accidents and injuries: The primary goal of safety training is to equip forklift operators with the knowledge and skills necessary to operate the equipment safely. By understanding the proper techniques, hazard identification, and risk management, operators can significantly reduce the likelihood of accidents and injuries.

- Promotes a safety culture: Safety training creates a culture of awareness and responsibility within the workplace. When employees receive comprehensive training, they become more vigilant and proactive about safety, leading to a safer working environment for everyone.

- Protects equipment and reduces downtime: Accidents not only harm employees but can also cause significant damage to forklifts and other warehouse equipment. By investing in safety training, you protect your valuable assets and minimize costly repairs and downtime.

The Components of Effective Safety Training

Effective safety training goes beyond a mere lecture or a set of videos. To ensure its effectiveness, it should incorporate several key components:

- Classroom instruction: This component covers the theoretical aspects of forklift operations, including safe driving techniques, load handling, and general safety guidelines.

- Practical training: As the saying goes, practice makes perfect. Practical training allows forklift operators to apply the knowledge they gained in the classroom setting. They get hands-on experience with operating a forklift under the guidance of experienced trainers.

- Site-specific training: Every warehouse is unique, with its layout, obstacles, and specific challenges. Site-specific training takes into account these factors and provides tailored guidance to operators, ensuring they are familiar with the specific conditions of their workplace.

- Regular refresher courses: Safety training is not a one-time event. Regular refresher courses are essential to remind operators of safety protocols and reinforce good habits. Ongoing training ensures that forklift operators stay up to date with the latest safety practices.

At HCO Innovations, we offer comprehensive safety training programs designed specifically for forklift operators. Our experienced trainers provide a blend of theoretical and practical training, tailored to the unique needs of your warehouse. We collaborate closely with your team to develop site-specific training protocols and offer regular refresher courses to ensure continued safety.

The Benefits of Safety Training

The benefits of safety training extend beyond accident prevention. When you prioritize safety in your warehouse operations, you can experience a range of positive effects:

- Improved productivity: Safety training helps operators become more efficient and confident in their abilities, leading to improved productivity levels.

- Reduced downtime: By minimizing accidents and equipment damage, safety training reduces downtime and keeps operations running smoothly.

- Enhanced employee morale: When employees feel safe and secure in their working environment, morale improves, leading to higher job satisfaction and employee retention.

- Cost savings: Investing in safety training may seem like an expense, but it can result in significant cost savings in the long run. Fewer accidents mean reduced workers' compensation claims, insurance premiums, and equipment repairs.

At HCO Innovations, we have witnessed the positive impact of safety training on businesses across various industries. Our tailored training programs have helped clients achieve significant reductions in accidents and injuries, leading to improved operational efficiency and cost savings.

HCO Innovations is committed to helping businesses optimize their warehouse operations and ensure the safety of their employees. Contact us today to learn more about our comprehensive safety training programs and how we can assist you in preventing forklift accidents.