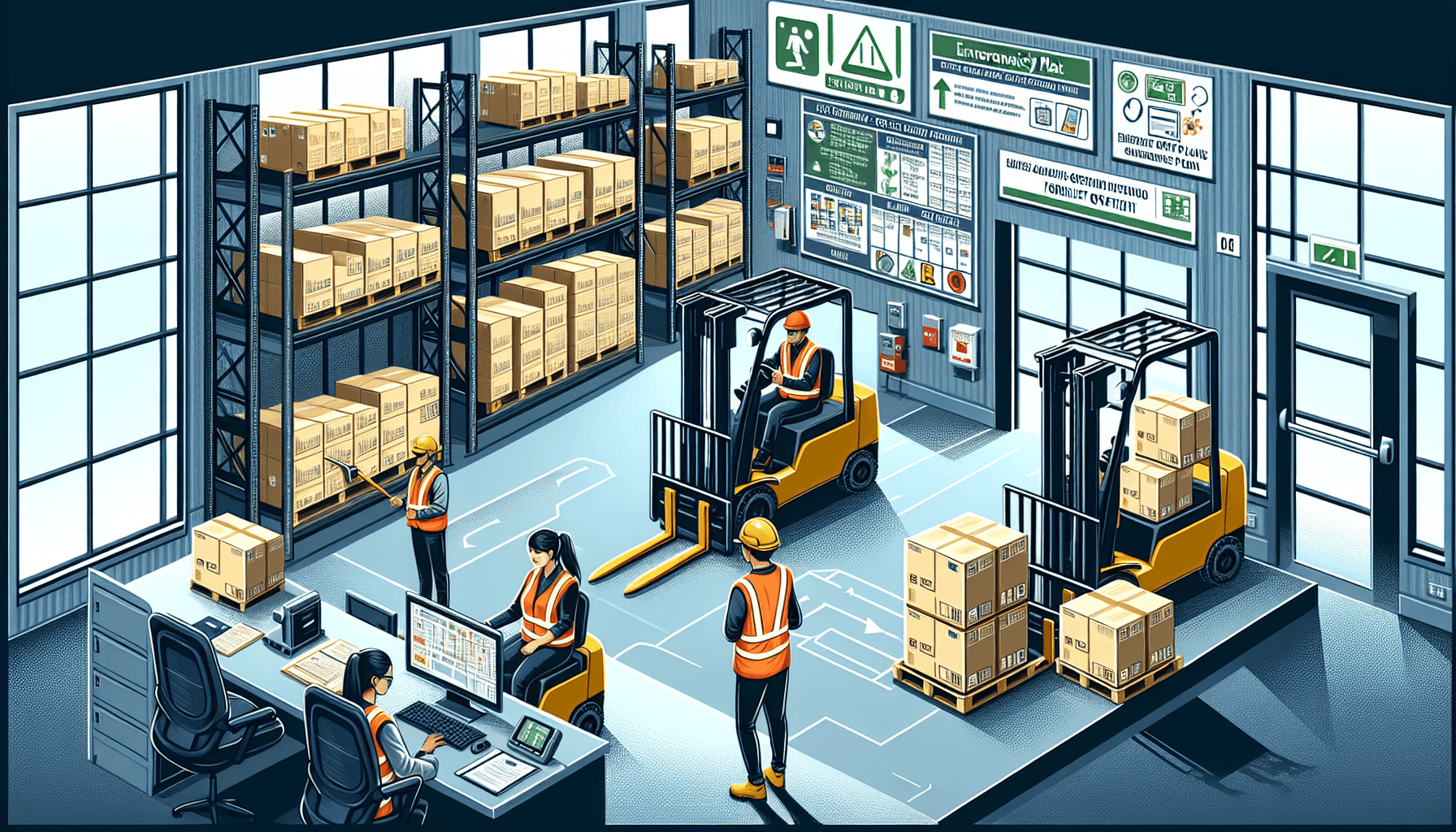

When it comes to running a successful warehouse operation, safety should be a top priority. A safe working environment not only protects employees from injury but also contributes to overall business continuity. One crucial aspect of warehouse safety is forklift safety. Forklifts are commonly used in warehouse operations to move heavy loads over short distances. However, if not used properly, they can pose significant risks to both operators and other warehouse employees. In this article, we will explore the role of forklift safety in business continuity planning and why it is so important for warehouse operations.

The Costs of Forklift Accidents

Before we dive into the role of forklift safety in business continuity planning, it is essential to understand the potential costs associated with forklift accidents. Forklift accidents can result in severe injuries to operators and other employees, leading to medical expenses, workers’ compensation claims, and potential lawsuits. In addition to the human cost, forklift accidents can also cause damage to warehouse infrastructure, equipment, and inventory, resulting in significant financial losses for the business.

Furthermore, when a forklift accident occurs, it can disrupt the overall workflow and productivity of the warehouse. The time spent dealing with an accident, investigating its causes, and repairing any damages can cause delays in fulfilling orders and meeting customer demands. This can lead to dissatisfied customers, lost business opportunities, and damage to the company’s reputation. Therefore, it is crucial to have proper forklift safety measures in place to prevent accidents and ensure business continuity.

The Role of Forklift Safety in Business Continuity Planning

Effective forklift safety measures play a critical role in business continuity planning for warehouse operations. By prioritizing forklift safety, businesses can minimize the risks of accidents and their associated costs. Here are some key reasons why forklift safety is essential for business continuity:

- Protecting Employees: The safety and well-being of employees should always be a priority for businesses. By ensuring that proper forklift safety protocols are in place, businesses can protect their employees from potential accidents and injuries. This not only reduces human suffering but also creates a positive work environment where employees feel valued and cared for.

- Maintaining Productivity: Forklift accidents can disrupt the workflow and productivity of a warehouse. By implementing robust forklift safety measures, such as regular training and inspections, businesses can minimize the chances of accidents occurring. This helps to maintain a smooth and efficient operation, ensuring that orders are fulfilled on time and customer demands are met.

- Preserving Equipment and Inventory: Forklift accidents can lead to damage to warehouse infrastructure, equipment, and inventory. By promoting forklift safety, businesses can minimize the likelihood of accidents that could result in costly repairs or replacements. This helps to protect the company’s assets and financial stability.

- Reducing Costs: Forklift accidents can result in significant financial costs, including medical expenses, workers’ compensation claims, and potential legal fees. By investing in forklift safety measures, businesses can reduce these costs, freeing up resources to invest in other areas of the operation. This contributes to long-term business continuity and profitability.

Implementing proper forklift safety measures requires a comprehensive approach that includes training programs, regular equipment maintenance and inspections, clear signage and markings, and strict adherence to safety guidelines and protocols. Businesses should also consider conducting regular warehouse safety evaluations to identify any potential hazards and make necessary improvements to ensure forklift safety and prevent accidents.

At HCO Innovations, we recognize the critical importance of forklift safety in warehouse operations. Our warehouse optimization solutions include comprehensive safety evaluations that assess all aspects of your warehouse operations, including forklift safety. Our team of experts will work closely with you to identify potential risks and develop tailored solutions to enhance safety, productivity, and efficiency within your warehouse. Click here to learn more about our warehouse safety evaluation.

Conclusion

Forklift safety plays a vital role in business continuity planning for warehouse operations. By prioritizing forklift safety, businesses can protect their employees, maintain productivity, preserve equipment and inventory, and reduce costs. Implementing proper forklift safety measures requires a comprehensive approach, including training, maintenance, signage, and adherence to safety protocols. With HCO Innovations’ warehouse optimization solutions, businesses can enhance safety, productivity, and efficiency, ensuring a smooth and uninterrupted operation.