When it comes to running a successful warehouse operation, one of the top priorities is ensuring forklift safety. Forklifts are essential tools for moving heavy loads and materials efficiently within the warehouse, but they can also pose serious risks if not operated properly. This is especially true in the context of global operations, where warehouses may have to navigate different regulations, cultural differences, and language barriers.

The Importance of Forklift Safety in Global Operations

In global operations, warehouses face unique challenges when it comes to ensuring forklift safety. These challenges arise from the diverse nature of work environments, varying safety regulations, and potential communication barriers. However, regardless of these challenges, forklift safety should be a top priority for all warehouses operating globally.

One of the key reasons why forklift safety is crucial in global operations is to avoid accidents and injuries. Forklift accidents can result in serious injuries or even fatalities, causing harm to workers, damaging equipment and inventory, and impacting productivity. By implementing strict safety protocols and providing proper training, warehouses can significantly reduce the risk of accidents.

Furthermore, forklift accidents can lead to costly legal issues and damage a company’s reputation. In global operations, warehouses may have to adhere to different safety regulations and standards depending on the location. Failure to comply with these regulations can result in fines, legal penalties, and even the suspension of operations. Adhering to safety regulations not only protects workers but also helps maintain a positive brand image and business reputation.

To ensure forklift safety in global operations, warehouses can follow these essential tips:

- Provide Comprehensive Forklift Training: All forklift operators, regardless of their location, should receive thorough training on forklift operation, safety procedures, and emergency protocols. This training should cover not only the technical aspects of operating a forklift but also the importance of adhering to safety regulations and best practices.

- Regular Inspections and Maintenance: Regular inspections and maintenance of forklifts are crucial in identifying any potential issues or malfunctions. This is especially important in global operations where warehouses may have a fleet of forklifts from different manufacturers. Conducting routine inspections and maintenance can help prevent accidents caused by faulty equipment.

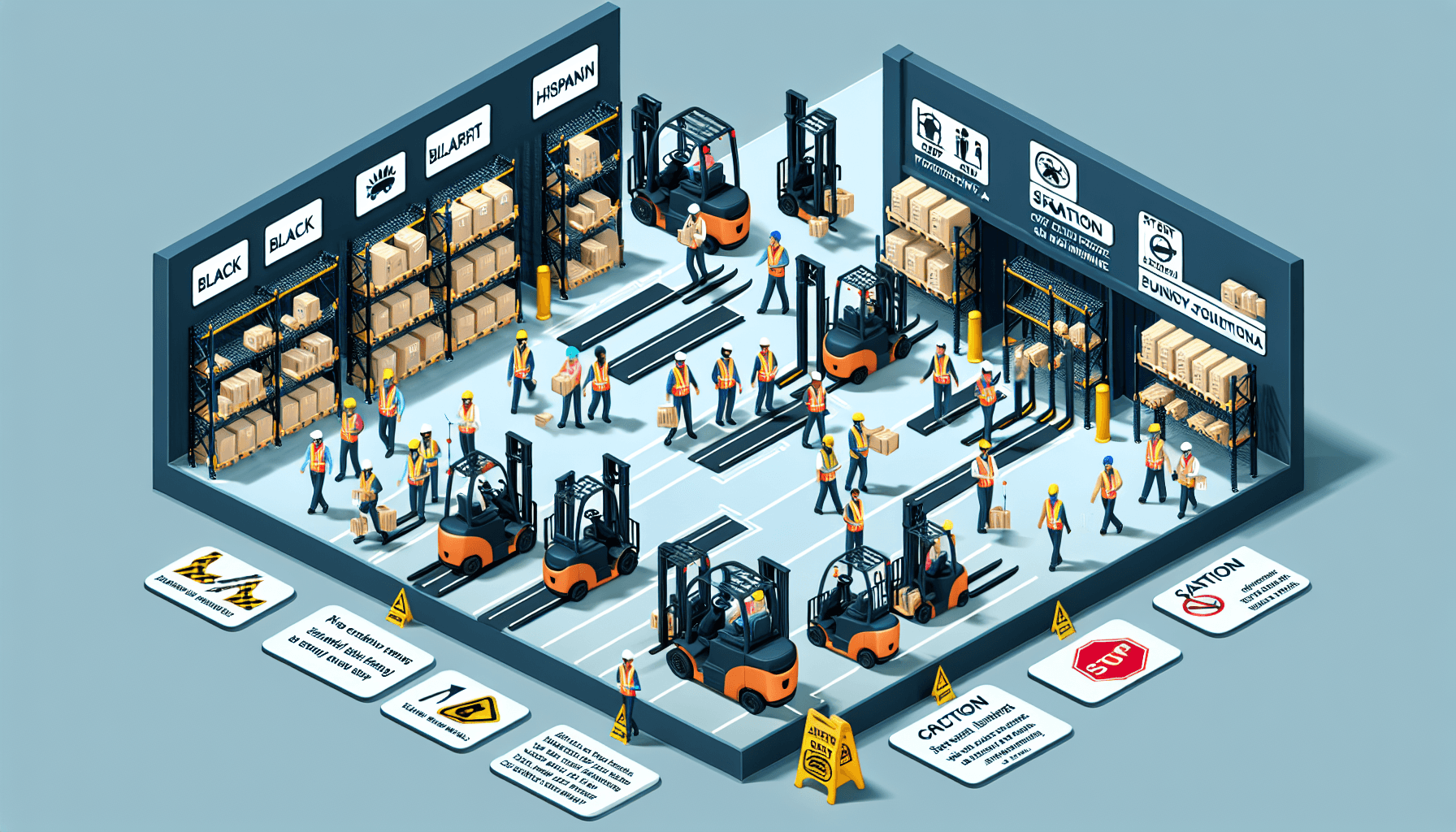

- Implement Clear Signage and Visual Communication: In global operations, language barriers can pose communication challenges. Implementing clear signage and visual communication methods, such as color-coded floor markings and safety signs, can help convey important safety information regardless of language barriers.

- Encourage Reporting of Near Misses and Incidents: Foster a culture of reporting near misses and incidents. Encourage workers to report any potential hazards, near misses, or accidents, regardless of their severity. This information can help identify potential safety risks and allow for corrective actions to be taken to prevent future incidents.

- Regular Safety Audits and Training Refreshers: Conduct regular safety audits to assess compliance with safety procedures and identify any areas that require improvement. Additionally, provide refresher training to forklift operators to reinforce safe operating practices and update them on any changes in safety regulations.

Implementing these tips can contribute to safer forklift operations in global warehouses. However, it is important to note that every warehouse is unique, and additional safety measures may be required based on the specific needs and challenges of the operation.

If you’re looking to optimize the safety of your warehouse operations, HCO Innovations is here to help. Our warehouse safety evaluation services can identify potential safety hazards, assess compliance with safety regulations, and provide recommendations for improvement. Our aim is to enhance safety, productivity, efficiency, and cost-effectiveness within your warehouse operations.

For more information on our warehouse safety evaluation services, visit HCO Innovations.

Remember, forklift safety is paramount to the success of any warehouse, especially in the context of global operations. By prioritizing safety, warehouses can create a safer work environment, prevent accidents and injuries, and establish a strong reputation in the industry.