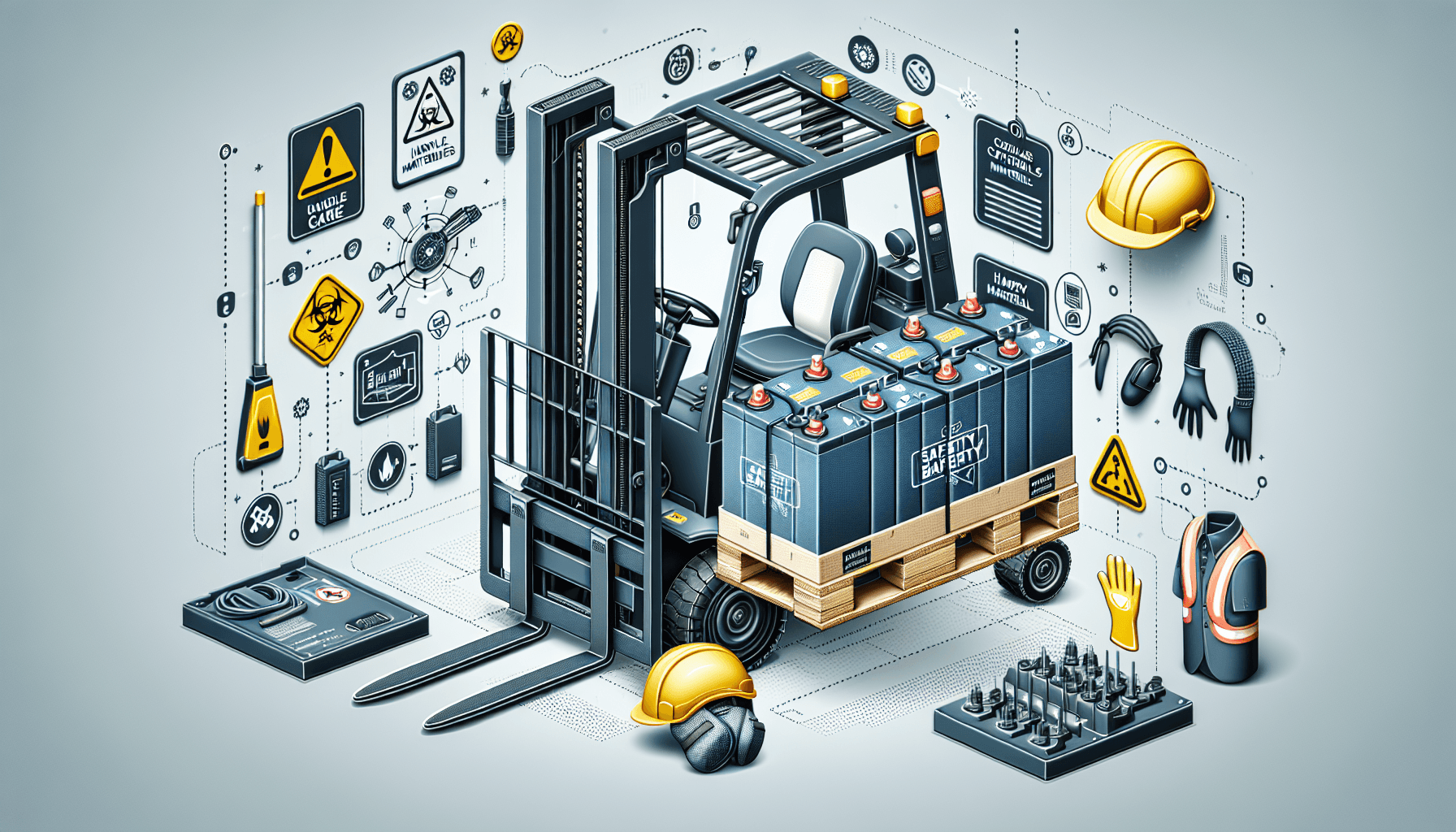

Transporting forklift batteries safely is crucial to ensure the smooth operation of warehouse operations. Forklift batteries are heavy and contain hazardous substances, which can pose risks if not handled properly. In this article, we will provide you with essential tips and guidelines on how to safely transport forklift batteries.

1. Proper Packaging and Handling

The first step in ensuring the safe transportation of forklift batteries is to ensure they are properly packaged and handled. This includes:

- Use Suitable Packaging: Use specially designed containers or packaging materials that are specifically designed for transporting batteries. These containers should be made of durable and non-conductive materials to prevent any leaks or damage.

- Secure and Seal: Properly secure and seal the battery containers to prevent any accidental openings during transportation. Use sturdy straps or fasteners to secure the containers in place.

- Handle with Care: Always handle the battery containers with care. Avoid dropping or mishandling them, as this can cause damage to the batteries and increase the risk of leaks or spills.

2. Adequate Ventilation

Proper ventilation is essential when transporting forklift batteries. Battery gases, such as hydrogen and oxygen, are released during normal operation and charging, which can accumulate and create a potential fire or explosion hazard. Here are some guidelines to ensure adequate ventilation:

- Open Spaces: Transport the batteries in a well-ventilated area, preferably with open windows or doors. This will help to dissipate any gases released by the batteries and reduce the risk of a buildup.

- Avoid Confined Spaces: Never transport forklift batteries in confined spaces, such as closed trucks or vans, without proper ventilation. Confined spaces can trap and concentrate battery gases, increasing the risk of an incident.

3. Follow Safety Regulations

Compliance with safety regulations is vital when it comes to transporting forklift batteries. There are specific regulations and guidelines set by regulatory bodies, such as the Department of Transportation (DOT) and the Occupational Safety and Health Administration (OSHA). Here are some key points to keep in mind:

- DOT Regulations: Familiarize yourself with the DOT regulations regarding the transportation of hazardous materials, including batteries. Ensure that all necessary labeling, placarding, and documentation requirements are met.

- OSHA Guidelines: OSHA provides guidelines for handling and storing hazardous materials, including batteries. Follow OSHA guidelines to ensure the safety of your employees and to comply with legal requirements.

- Training and Certification: Ensure that your employees involved in transporting forklift batteries receive proper training and certification. This will help them understand the safety procedures and precautions required during transportation.

4. Choose the Right Equipment

Using the right equipment is essential for safely transporting forklift batteries. Consider the following factors when selecting equipment:

- Suitable Vehicles: Choose vehicles that are suitable for transporting batteries. Ensure that the vehicles have appropriate safety features, such as secure battery racks, to prevent movement or damage during transit.

- Equipment for Lifting: Use proper equipment, such as forklifts or hoists, to lift and move the batteries. Ensure that the equipment is in good working condition and can handle the weight of the batteries.

- Protective Gear: Provide your employees with the necessary protective gear, such as gloves, safety glasses, and aprons, when handling and transporting batteries. This will protect them from any potential hazards.

By following these guidelines and best practices, you can ensure the safe transportation of forklift batteries. Remember, safety should always be a top priority in warehouse operations. To learn more about forklift fleet power management and optimization solutions, visit HCO Innovations.