Proper disposal of forklift batteries is crucial for the safety and sustainability of warehouse operations. In order to improve forklift battery disposal practices, it is important to understand the potential risks associated with improper disposal and explore effective strategies for responsible battery management.

The Environmental Impact of Improper Forklift Battery Disposal

Improper forklift battery disposal can have significant environmental consequences. Forklift batteries contain hazardous materials and toxic chemicals that can contaminate soil and water if not disposed of properly. Lead-acid batteries, which are commonly used in forklifts, contain lead, sulfuric acid, and other heavy metals that can be harmful to the environment if they leach into the soil or enter waterways.

When forklift batteries are not disposed of correctly, these toxic substances can seep into the ground, potentially polluting nearby water sources. This contamination can harm aquatic life and pose a threat to human health if consumed through contaminated drinking water or the consumption of contaminated fish.

Additionally, improper disposal methods can lead to air pollution. When batteries are incinerated or disposed of in landfills, harmful emissions can be released into the air, contributing to the depletion of ozone layer and air pollution.

The Importance of Responsible Battery Management

Responsible battery management is essential for mitigating the environmental impact of forklift operations. By implementing proper battery disposal practices, warehouse operators can protect the surrounding environment and minimize their ecological footprint. Responsible battery management also ensures compliance with environmental regulations and reduces the potential for fines and penalties.

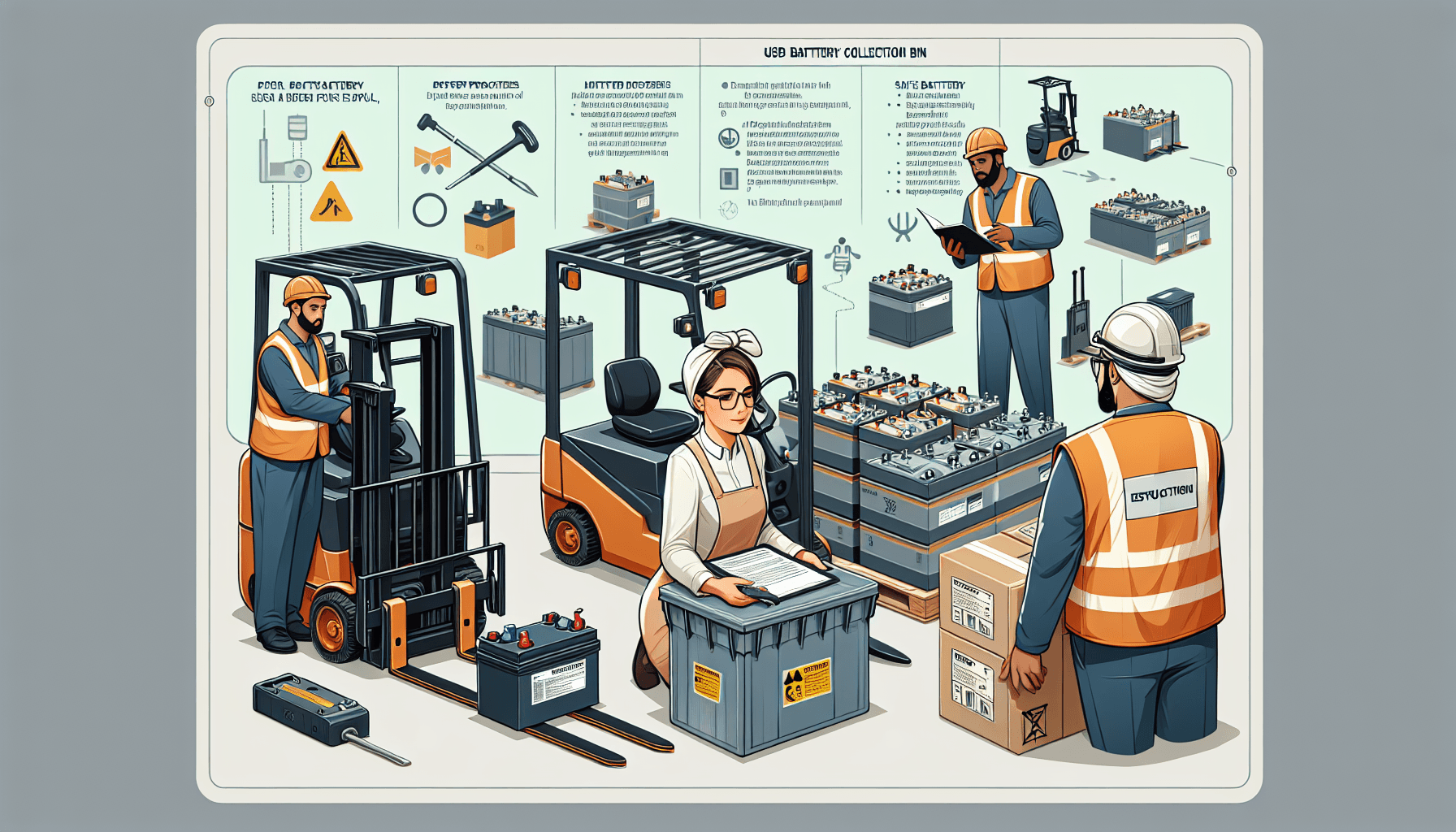

A proactive approach to forklift battery disposal involves the implementation of a comprehensive battery management program. This program should include guidelines for safe handling, storage, charging, maintenance, and disposal of forklift batteries. It is crucial to train employees on proper battery handling procedures and provide them with the necessary personal protective equipment (PPE).

One key aspect of responsible battery management is finding sustainable options for forklift battery disposal. Recycling is an excellent solution that can help minimize environmental impact. By recycling forklift batteries, the valuable materials can be recovered and reused, reducing the need for raw material extraction and minimizing waste.

Many reputable recycling facilities specialize in the proper disposal of forklift batteries. These facilities have the necessary infrastructure and expertise to safely recycle batteries and extract valuable resources. It is essential to partner with a certified recycling facility that adheres to strict environmental standards and complies with all applicable regulations.

Tips for Improving Forklift Battery Disposal Practices

Here are some tips to improve forklift battery disposal practices and promote responsible battery management:

- Educate Employees: Provide comprehensive training on proper battery handling, safety procedures, and the importance of responsible disposal.

- Implement a Battery Management Program: Develop and enforce guidelines for battery handling, storage, charging, maintenance, and disposal.

- Use Battery Monitoring Systems: Implement a battery monitoring system to optimize battery performance, track usage, and identify potential issues.

- Partner with a Certified Recycling Facility: Find a reputable recycling facility that specializes in forklift battery disposal and ensure they follow all necessary regulations.

- Regularly Inspect Batteries: Conduct routine inspections to identify any signs of deterioration or damage that may require immediate attention or battery replacement.

- Dispose of Defective Batteries Properly: Defective batteries should be handled according to the manufacturer’s instructions or disposed of through a certified recycling facility.

By following these tips and implementing responsible forklift battery disposal practices, warehouse operators can contribute to a cleaner and more sustainable environment while ensuring compliance with environmental regulations.

At HCO Innovations, we understand the importance of responsible battery management in warehouse operations. Our Forklift Fleet Power Management solutions are designed to optimize battery performance, extend battery life, and promote sustainable battery management practices. Contact us today to learn more about our innovative solutions and how we can help improve your warehouse operations.