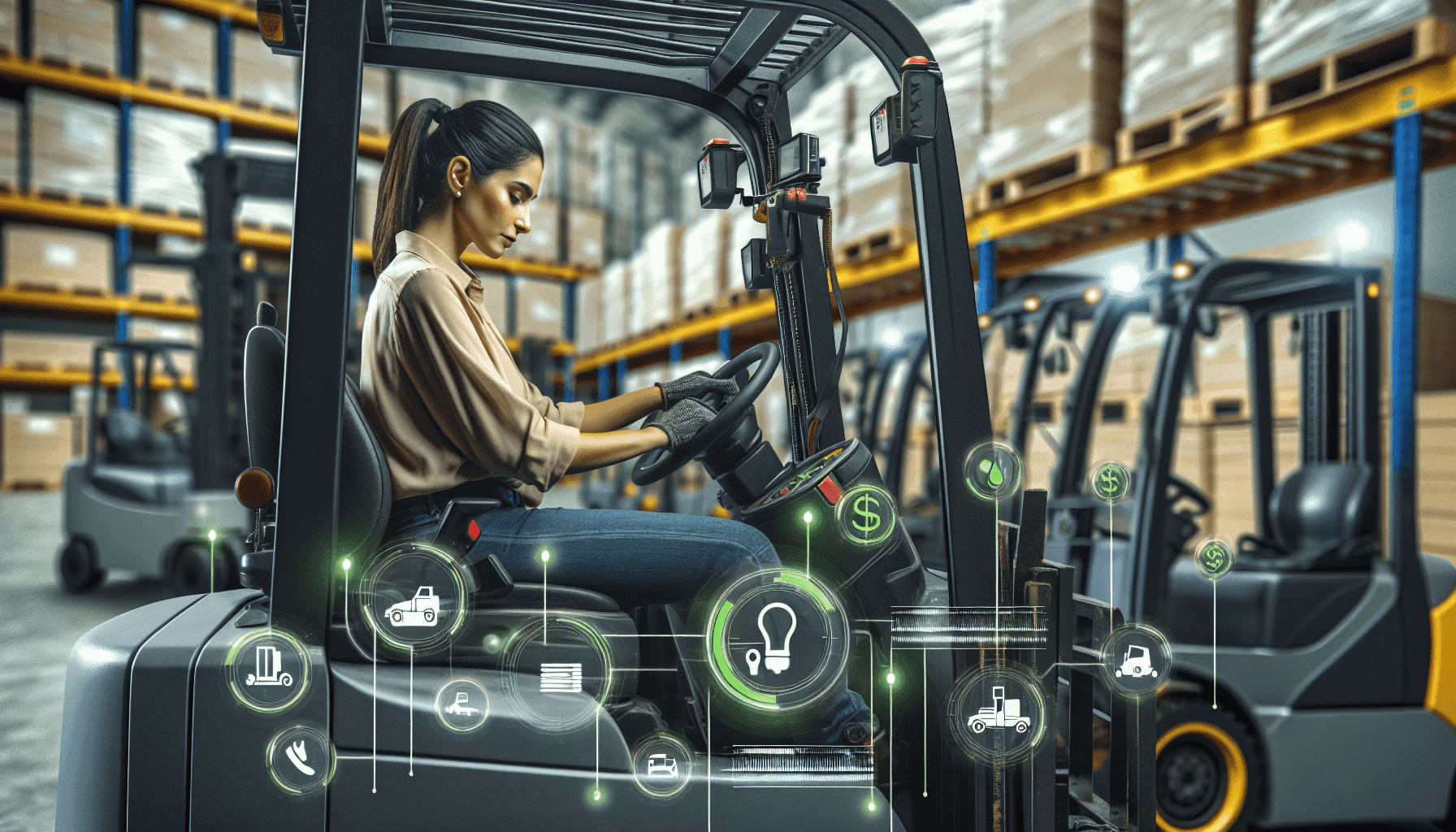

Have you ever wondered how you can reduce the costs associated with your forklift fleet? In a warehouse environment, forklifts play a crucial role in efficiently moving and storing goods. However, managing a forklift fleet can be a complex and costly task. That’s where telematics comes in. Telematics, the integration of telecommunications and informatics, provides a solution that can help optimize your forklift fleet operations and reduce costs.

The Benefits of Telematics for Forklift Fleet Management

Telematics technology allows for the monitoring and analysis of data from your forklift fleet in real-time. This data can include information such as the location, speed, fuel consumption, and maintenance needs of each forklift. By leveraging this data, you can gain valuable insights into your fleet operations and make informed decisions to improve efficiency and reduce costs. Here are some of the key benefits of using telematics for forklift fleet management:

- Improved Safety: Safety is paramount in any warehouse environment. Telematics can provide real-time information on operator behavior, such as speeding or harsh braking, allowing you to identify and address safety concerns. It can also track and monitor forklift maintenance schedules, ensuring that they are regularly serviced and in optimal working condition.

- Increased Productivity: Telematics enables you to monitor your forklift fleet’s performance and identify areas where productivity can be improved. For example, you can analyze data to determine the most efficient routes for navigation and make adjustments to optimize workflow. This can result in faster turnaround times, increased throughput, and ultimately, improved productivity levels.

- Reduced Downtime: With telematics, you can proactively schedule maintenance for your forklifts based on their usage data. This preventative maintenance approach helps to prevent breakdowns and costly unscheduled repairs. By reducing downtime due to mechanical issues, you can ensure maximum uptime for your forklift fleet.

- Optimized Fuel Consumption: Telematics provides insights into fuel usage patterns, allowing you to identify any inefficiencies and take steps to optimize fuel consumption. By optimizing routes, reducing idle time, and addressing any excessive fuel consumption patterns, you can significantly reduce fuel costs.

- Better Cost Control: By having access to real-time data on your forklift fleet’s usage, maintenance, and performance, you can identify cost-saving opportunities. This includes reducing unnecessary operational expenses, optimizing resource allocation, and making informed decisions regarding fleet size and composition.

Implementing telematics for your forklift fleet management can have a profound impact on your bottom line. It allows you to have a comprehensive understanding of your fleet operations, make data-driven decisions, and optimize efficiency to drive cost savings. By investing in telematics, you can gain a competitive edge and position your warehouse operations for success.

Interested in exploring how telematics can benefit your forklift fleet management? At HCO Innovations, we offer cutting-edge warehouse optimization solutions that include telematics for improved forklift fleet management. Our solutions are designed to enhance safety, productivity, efficiency, and cost-effectiveness within warehouse operations. Contact us today to learn more about how we can help you optimize your forklift fleet and reduce costs.