In any warehouse operation, forklifts play a critical role in material handling and keeping operations running smoothly. These powerful machines are essential for lifting, moving, and stacking heavy items, but they also require regular maintenance to ensure optimal performance and safety.

The Importance of Forklift Maintenance

Maintaining forklifts is crucial for several reasons:

- Extended Lifespan: Regular maintenance can extend the lifespan of your forklifts, allowing you to get the most out of your investment.

- Improved Safety: Well-maintained forklifts are less likely to malfunction, reducing the risk of accidents and injuries in the workplace.

- Enhanced Productivity: Properly maintained forklifts operate more efficiently, resulting in increased productivity and reduced downtime.

- Cost Savings: By addressing minor issues before they become major problems, you can avoid costly repairs or the need for premature equipment replacement.

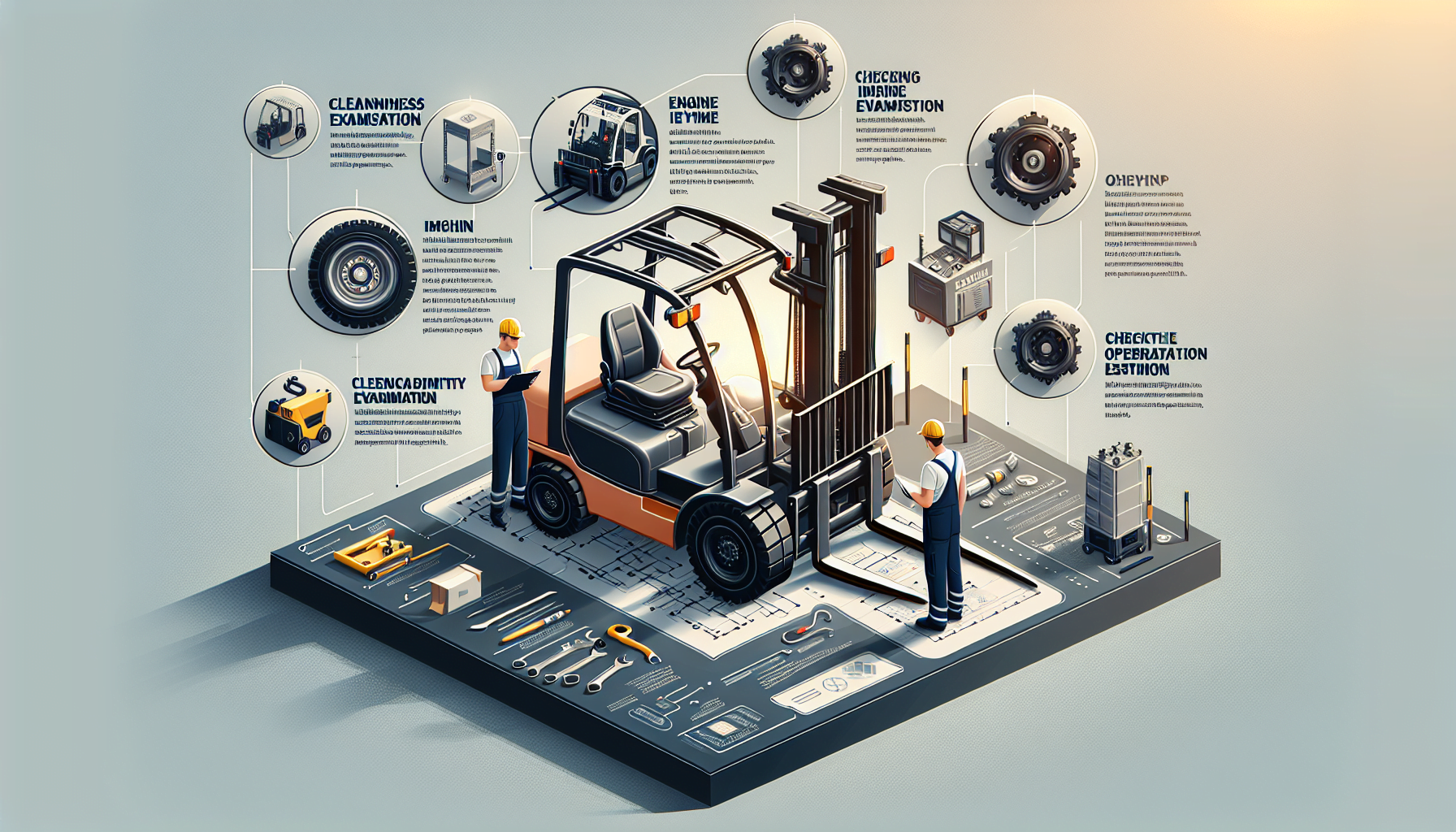

If you want to ensure your forklifts are operating at their best, conducting regular maintenance evaluations is essential. Here are some steps to help you conduct an effective forklift maintenance evaluation:

Step 1: Create a Maintenance Schedule

The first step is to establish a maintenance schedule to ensure regular inspections and servicing. This schedule should include routine checks, such as daily, weekly, monthly, and annual inspections.

Daily inspections should be performed by the operators before using the forklifts and focus on basic safety checks, such as examining tires, brakes, lights, and fluid levels. Weekly inspections can involve more detailed checks, including the condition of hoses, belts, and filters. Monthly inspections can include checking for proper lubrication and conducting battery maintenance. Lastly, annual inspections should be conducted by qualified technicians to thoroughly inspect and service the forklifts.

By following a maintenance schedule, you can catch potential issues early on and address them promptly.

Step 2: Train Operators for Visual Inspections

Operators should be trained to conduct visual inspections before using the forklifts. This includes checking for any visible damage, leaks, loose or damaged components, and worn-out tires. Operators should also look for signs of wear and tear in the cabin, such as torn seats or broken mirrors.

If any issues are found, operators should report them immediately to the maintenance team, who can then take appropriate action to resolve the problem.

Step 3: Conduct Regular Equipment Checks

In addition to visual inspections, it is important to conduct regular equipment checks to ensure all components are functioning properly.

This can include:

- Checking the brakes for effectiveness and responsiveness.

- Testing the horn, lights, and other safety features.

- Inspecting the lifting mechanism for smooth operation.

- Checking the steering for any issues or excessive play.

- Examining the forks, chains, and other load-bearing components for wear or damage.

Any identified issues should be addressed immediately to prevent further damage or safety risks.

Step 4: Document and Track Maintenance

To ensure accountability and stay organized, it is crucial to document and track all maintenance activities.

This includes:

- Keeping records of inspections, repairs, and maintenance tasks performed.

- Tracking any recurring issues or patterns.

- Noting any replacement parts used.

- Keeping a maintenance log for each individual forklift.

Having a detailed maintenance history not only helps in identifying trends but also provides valuable information when it comes to selling or replacing the forklift.

By maintaining accurate records, you can also ensure that inspections and maintenance are conducted on schedule and in compliance with regulatory requirements.

Conclusion

In conclusion, conducting regular forklift maintenance evaluations is crucial for the smooth operation, safety, and longevity of your forklifts. By following a maintenance schedule, training operators for visual inspections, conducting regular equipment checks, and documenting maintenance activities, you can ensure that your forklifts are always in optimal condition.

To learn more about turnkey forklift maintenance solutions, visit HCO Innovations.