The Role of Forklift Maintenance in Reducing Total Cost of Ownership

Introduction

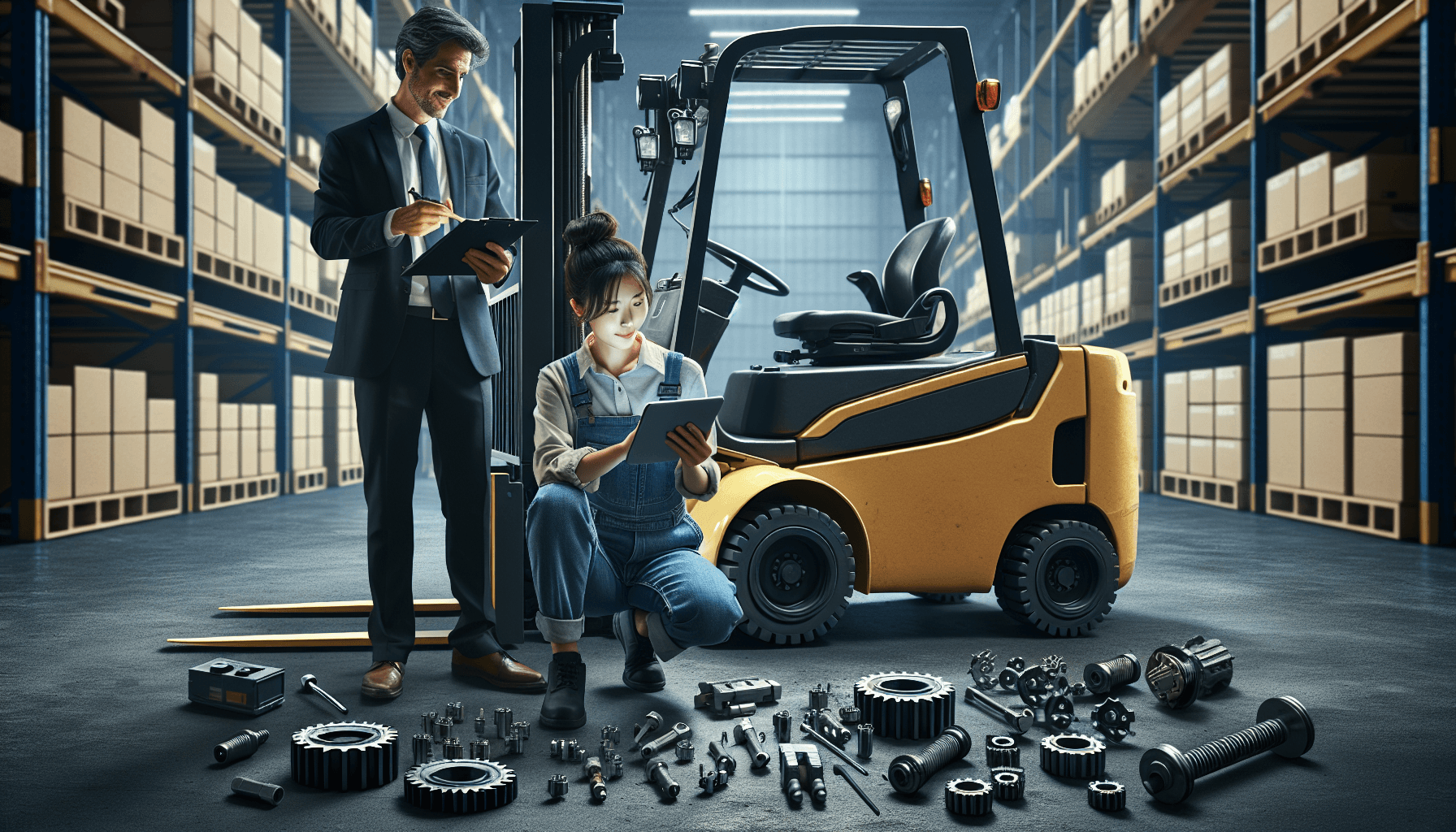

Forklifts play a crucial role in warehouse operations. They are the workhorses that help move heavy loads and maximize productivity. However, owning and maintaining forklifts can be a significant expense for businesses. That’s where the importance of regular forklift maintenance comes into play. By implementing a comprehensive maintenance program, businesses can reduce their total cost of ownership and ensure the longevity of their forklift fleet.

The Cost of Poor Forklift Maintenance

When forklifts are not properly maintained, it can lead to a variety of issues that can negatively impact a warehouse’s operations and budget. Here are some common costs associated with poor forklift maintenance:

- Increased Repair Costs: Neglected forklifts are more likely to experience breakdowns and require costly repairs. These unexpected expenses can quickly add up and strain a business’s budget.

- Reduced Productivity: When a forklift breaks down, it not only disrupts the workflow but also hampers overall productivity. Downtime due to maintenance issues can lead to delayed shipments and unhappy customers.

- Safety Risks: A poorly maintained forklift poses safety risks to operators and other warehouse workers. Malfunctioning parts, worn-out tires, and faulty brakes can result in accidents and injuries, leading to even more expenses.

- Decreased Lifespan: Regular maintenance helps to identify and address potential issues before they escalate. By neglecting maintenance, forklifts are more likely to experience premature wear and tear, reducing their overall lifespan.

The Benefits of Regular Forklift Maintenance

Implementing a proactive maintenance strategy for forklifts can yield several benefits for businesses. Here are some advantages of regular forklift maintenance:

- Improved Performance: Well-maintained forklifts operate at peak performance, ensuring smooth and efficient operations within the warehouse. This leads to increased productivity and overall operational success.

- Reduced Downtime: By conducting regular inspections and addressing any maintenance needs promptly, businesses can minimize unexpected breakdowns and reduce costly downtime. This allows operations to run smoothly without interruptions.

- Enhanced Safety: Forklifts that undergo regular maintenance are less prone to accidents and safety hazards. This not only protects the well-being of operators and employees but also safeguards the business from potential legal and financial consequences.

- Extended Lifespan: Regular maintenance helps identify and address potential issues early on, preventing them from escalating into major problems. By properly caring for forklifts, businesses can prolong their lifespan, maximizing their return on investment.

- Cost Savings: Investing in regular forklift maintenance may seem like an additional expense, but it actually helps businesses save money in the long run. By preventing major repairs and breakdowns, businesses can avoid costly emergency repairs and replacement expenses.

Implementing a Forklift Maintenance Program

Developing and implementing a comprehensive forklift maintenance program is critical for reducing the total cost of ownership and optimizing warehouse operations. Here are some key steps to consider:

- Schedule Regular Inspections: Create a schedule for regular inspections and maintenance tasks. This can include checking fluid levels, inspecting tires, testing brakes, and ensuring all safety features are functioning properly.

- Train Operators: Provide training to forklift operators on proper daily maintenance tasks and procedures. Encourage them to report any issues or abnormalities they notice during their operations.

- Partner with a Reliable Maintenance Provider: Consider outsourcing forklift maintenance to a reputable provider like HCO Innovations. Their turnkey forklift maintenance solutions offer comprehensive services that include routine maintenance, emergency repairs, and parts replacements. By leveraging their expertise, businesses can ensure their forklifts receive the necessary care and attention they need to remain in optimal condition.

- Keep Detailed Maintenance Records: Maintain accurate records of all maintenance activities, including inspections, repairs, and part replacements. This helps track the maintenance history of each forklift and provides valuable insights for future maintenance planning.

- Continuous Improvement: Regularly evaluate and refine your maintenance program. Identify areas for improvement and implement changes as needed. Stay updated with industry best practices and emerging technologies to optimize your program further.

By following these steps and prioritizing regular forklift maintenance, businesses can significantly reduce their total cost of ownership and enjoy the benefits of improved performance, increased productivity, enhanced safety, and extended lifespan of their forklift fleet.

Investing in forklift maintenance is not just an expense; it is a strategic decision that can optimize warehouse operations, minimize costs, and contribute to the overall success of a business.

Learn more about HCO Innovations’ turnkey forklift maintenance solutions and how they can help businesses streamline their maintenance processes and reduce their total cost of ownership.