Forklift batteries are a crucial component of warehouse operations. They provide the power needed to keep forklifts running and enable the efficient movement of goods within a warehouse. However, ensuring that forklift batteries are properly charged is essential for maximizing their lifespan and performance. In this article, we will explore some of the best practices for charging forklift batteries that can help warehouse managers optimize their operations and minimize downtime.

1. Establish a Charging Schedule

One of the most important best practices for charging forklift batteries is to establish a regular charging schedule. Developing a consistent routine helps ensure that batteries are consistently charged and ready for use. It is recommended to charge forklift batteries at the end of each shift or when the charge drops to a certain level, typically around 20-30% capacity. Charging batteries too soon or too late can have a negative impact on their lifespan.

It is also essential to avoid overcharging forklift batteries. Overcharging can lead to increased water consumption and excessive heat, which can shorten the battery’s lifespan. Using an advanced battery management system, like the one offered by HCO Innovations, can help monitor and regulate the charging process, ensuring batteries are charged safely and efficiently.

2. Provide Adequate Charging Infrastructure

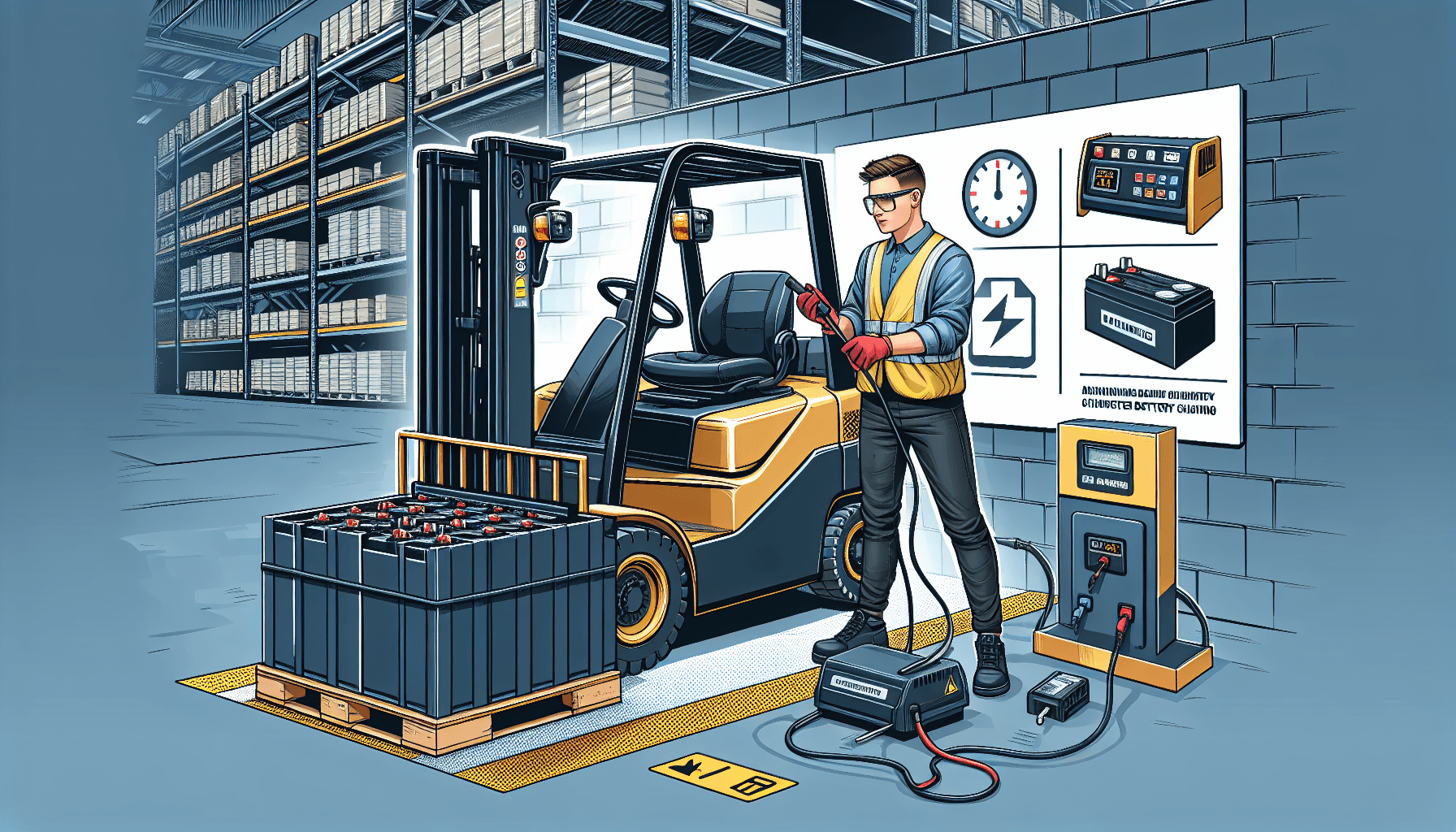

Having proper charging infrastructure in place is another critical factor in optimizing forklift battery charging. Warehouses should invest in sufficient charging stations and equipment to accommodate the number of forklifts in operation. This includes having enough charging cables, connectors, and storage areas for spare batteries.

In addition, it is important to provide a well-ventilated and temperature-controlled charging area to prevent overheating of batteries. Extreme temperatures can negatively affect battery performance and lifespan. Proper ventilation helps dissipate heat generated during the charging process, reducing the risk of battery damage and extending their overall longevity.

3. Implement Battery Handling and Maintenance Protocols

To ensure the longevity and optimal performance of forklift batteries, it is essential to follow proper handling and maintenance protocols. Proper battery handling includes using suitable lifting equipment, such as battery changing carts or hoists, to prevent dropping or damaging batteries during replacement or charging.

Regular battery maintenance is also crucial. This includes visually inspecting batteries for any signs of damage or corrosion, cleaning battery terminals and connectors, and checking electrolyte levels if applicable. Implementing preventive maintenance schedules can help identify and address any battery issues before they impact performance or safety.

4. Train Operators on Battery Charging Procedures

Training forklift operators on proper battery charging procedures is vital to ensure they follow the established best practices. Operators should be aware of how to connect and disconnect batteries safely, as well as the charging voltage and time required for a complete charge. Educating operators on the importance of adhering to the charging schedule and avoiding common charging errors can help minimize battery-related issues.

HCO Innovations offers comprehensive training programs for warehouse staff, including forklift operators, on battery charging and maintenance best practices. Equipping your workforce with the necessary knowledge and skills can greatly contribute to the overall success and efficiency of your warehouse operations.

5. Consider Implementing Battery Monitoring and Management Solutions

Advances in technology have led to innovative battery monitoring and management solutions that can significantly enhance the efficiency and lifespan of forklift batteries. These solutions utilize advanced sensors, telemetry, and software to track battery performance, providing real-time data on battery state-of-charge, temperature, and overall health.

By implementing battery monitoring and management solutions, warehouse managers can gain valuable insights into battery usage patterns, identify potential issues, and optimize battery charging and usage. This data-driven approach can help minimize downtime, reduce battery replacement costs, and improve overall operational efficiency.

In conclusion, following best practices for charging forklift batteries is crucial for optimizing warehouse operations. Establishing a regular charging schedule, providing adequate infrastructure, implementing proper handling and maintenance protocols, training operators, and considering advanced battery monitoring solutions are all key steps towards maximizing battery performance and lifespan. By prioritizing battery charging practices, warehouse managers can enhance safety, productivity, efficiency, and cost-effectiveness within their operations.