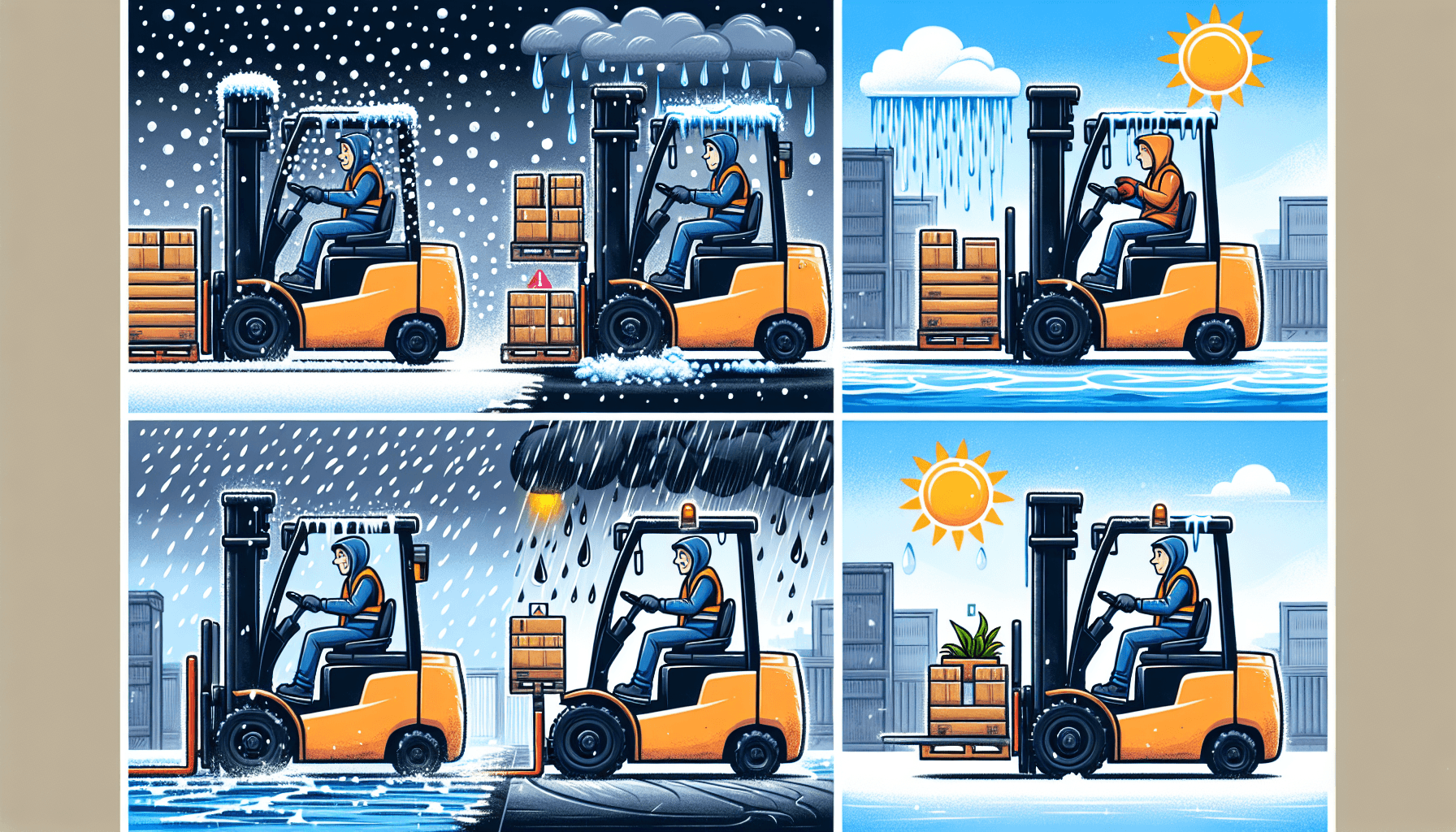

Weather conditions can have a significant impact on the safety of forklift operations in warehouses. Forklifts play a crucial role in warehouse operations, handling heavy loads and moving them efficiently. However, adverse weather conditions can pose additional challenges and risks to forklift operators and other warehouse personnel. In this article, we will explore the various ways in which weather conditions can affect forklift safety and discuss strategies for mitigating these risks.

1. Rain and Wet Surfaces

One of the most common weather conditions that can impact forklift safety is rain. When it rains, the warehouse floor surfaces can become wet and slippery, which increases the risk of forklifts skidding or losing traction. This can lead to accidents such as tip-overs or collisions with other equipment or warehouse structures.

To mitigate the risks associated with wet surfaces, it is essential to have proper drainage systems in place to prevent water accumulation on the warehouse floor. Implementing non-slip floor coatings or installing anti-skid mats in high-risk areas can also improve traction and reduce the likelihood of accidents.

Furthermore, forklift operators should receive training on safe operating practices in wet conditions, including maintaining a safe speed, increasing braking distance, and using appropriate caution when turning or reversing on slippery surfaces.

Regular warehouse safety evaluations can help identify areas that require additional precautions or improvements to ensure optimal safety in various weather conditions, including rain and wet surfaces.

2. Extreme Temperatures

Extreme temperatures, whether extreme heat or extreme cold, can also impact forklift safety. In excessively hot conditions, forklift operators may experience discomfort, fatigue, and dehydration, which can affect their concentration and decision-making abilities. On the other hand, extremely cold temperatures can cause materials and surfaces to become brittle, increasing the risk of accidents and equipment damage.

To address extreme temperatures, it is crucial to provide appropriate climate control in warehouse facilities. This can include installing insulation, ventilation systems, or air conditioning units to regulate the temperature and ensure a comfortable working environment for forklift operators. Implementing regular breaks and hydration protocols in hot conditions and providing suitable protective gear such as insulated gloves in cold conditions are also necessary measures to maintain forklift safety.

Training programs should also cover the effects of extreme temperatures on forklift operations and emphasize the importance of monitoring and responding to changes in temperature accordingly.

3. Strong Winds

Strong winds can pose a significant safety risk in outdoor warehouse areas or warehouses with open doors or windows. High winds can destabilize forklifts and cause them to tip over or deviate from their intended path. Additionally, flying debris or loose objects can be hazardous and cause injuries to both forklift operators and other personnel.

To minimize the impact of strong winds, it is important to maintain a clear and organized warehouse layout, ensuring that loose objects are properly secured or stored away. Regular inspections of outdoor areas should be conducted to identify any potential hazards such as loose signage, tree branches, or debris that can be moved by strong winds.

In extreme weather conditions, it may be necessary to limit or suspend forklift operations until the winds subside to ensure the safety of all personnel.

Conclusion

Weather conditions can significantly impact forklift safety in warehouse operations. Rain and wet surfaces increase the risk of skidding and collisions, extreme temperatures can affect operator performance, and strong winds can destabilize forklifts and cause accidents. By implementing appropriate safety measures, conducting regular evaluations, and providing comprehensive training to forklift operators, warehouse managers can mitigate the risks associated with adverse weather conditions and ensure a safer working environment for all personnel.

In need of a warehouse safety evaluation? Contact HCO Innovations, the leading provider of warehouse optimization solutions. Their expertise in enhancing safety, productivity, efficiency, and cost-effectiveness within warehouse operations can help you identify potential risks and implement effective solutions.

Q: How does rain affect forklift safety?

A: Rain can make surfaces slippery and reduce traction, which is particularly dangerous for forklifts. It can increase the risk of skidding, sliding, and tipping over. It is crucial to exercise caution and reduce the speed when operating a forklift in rainy conditions. Additionally, operators should ensure that the forklift's tires have sufficient tread and proper inflation to maintain grip on wet surfaces.

Q: Can extreme heat impact forklift performance?

A: Yes, extreme heat can affect forklift performance and safety. High temperatures can cause batteries to overheat and reduce their lifespan. It is important to monitor battery temperature and properly maintain them. Operator fatigue can also be a concern in hot weather, affecting concentration and reaction times. Adequate breaks, hydration, and ventilation should be provided to minimize these risks.

Q: What precautions should be taken during snowy conditions?

A: When operating a forklift in snowy conditions, it's essential to clear the working area from snow and ice regularly. Accumulated snow can decrease traction, making it harder to control the forklift and increasing the risk of skidding. Equipping the forklift with appropriate tire chains or using specialized snow tires can improve grip. Additionally, adjusting driving speed and increasing the following distance is necessary to ensure safe operations.

Q: How does fog affect forklift safety?

A: Fog significantly reduces visibility, making it difficult for forklift operators to see potential hazards and obstacles in their path. It is crucial to activate fog lights and use caution when driving in foggy conditions. Slowing down, sounding the horn when necessary, and maintaining a safe distance from other vehicles and pedestrians are essential safety measures to follow during foggy weather.

Q: Can strong winds impact forklift stability?

A: Yes, strong winds can compromise the stability of forklifts, especially when they are carrying loads. The wind force can exert pressure on the load and cause instability, leading to tipping over. It is vital to assess wind speeds and take precautions accordingly. Operators should avoid driving in high winds or reduce speed, and secure loads properly to prevent them from toppling over due to gusty conditions.

Q: What steps should be taken during thunderstorms to ensure forklift safety?

A: During thunderstorms, it is crucial to move forklifts indoors or to a designated safe area, away from exposure to lightning strikes. Operators should not operate forklifts during thunderstorms due to the risks of electrical hazards and potential accidents caused by reduced visibility and unpredictable weather conditions. Safety should always be prioritized during severe weather events.

Safe Driving Tips for Forklift Operators in Extreme Weather Conditions

Extreme weather conditions can pose significant challenges for forklift operators. From heavy rain and snow to high winds and extreme temperatures, these conditions can greatly affect the safety and efficiency of warehouse operations. It is crucial for forklift operators to be prepared and aware of the potential risks associated with driving in these conditions. In this article, we will provide some useful tips to help forklift operators navigate extreme weather conditions safely and effectively.

1. Conduct Pre-Operational Inspections

Before operating a forklift in extreme weather conditions, it is essential to conduct a thorough pre-operational inspection. This includes checking the tires for adequate tread depth and inflation, inspecting the brakes and steering system, and ensuring all lights and signals are functioning properly. Additionally, make sure the windshield wipers and defrosting systems are working effectively to maintain clear visibility.

2. Slow Down and Maintain a Safe Distance

In extreme weather conditions, it is crucial to reduce speed and maintain a safe distance from other vehicles, objects, and pedestrians. Wet, snowy, or icy surfaces can significantly reduce traction, making it more challenging to stop or maneuver the forklift. By slowing down and keeping a safe distance, operators can effectively prevent accidents and maintain control of the forklift.

3. Use Proper Lighting

Poor visibility is a common issue in extreme weather conditions. To ensure maximum visibility, forklift operators should use proper lighting, including headlights, taillights, and turn signals. These lights will not only help the operator see their surroundings better but also make them more visible to others in the area, reducing the risk of collisions.

4. Be Aware of Multiple Hazards

Extreme weather conditions can create additional hazards in the warehouse environment. For example, heavy rain or snow can create slippery surfaces, while strong winds can cause debris or objects to become projectiles. Forklift operators need to be aware of these potential hazards and take appropriate precautions to prevent accidents and injuries. This may include removing obstacles, using floor mats or anti-slip coatings, and securing any loose objects or materials.

5. Stay Alert and Focused

In challenging weather conditions, it is crucial for forklift operators to stay alert and focused on their surroundings. This means avoiding distractions, such as using mobile devices or listening to music, as they can impede the operator's ability to react quickly and make sound decisions. By remaining attentive, operators can identify potential risks and make adjustments accordingly.

6. Dress Appropriately

Proper attire is essential for forklift operators working in extreme weather conditions. Operators should dress in layers to regulate body temperature and choose clothing that provides adequate protection from the elements. This includes wearing waterproof boots, gloves, and a high-visibility vest or jacket. By dressing appropriately, operators can remain comfortable and focused on the task at hand.

7. Follow Manufacturer's Guidelines

Each forklift model may have specific recommendations or limitations for operating in extreme weather conditions. It is essential for operators to familiarize themselves with the manufacturer's guidelines and follow them accordingly. This may include recommendations for maximum wind speeds, temperature limits, or specific precautions to take in certain weather conditions. By adhering to these guidelines, operators can ensure the safe and efficient operation of the forklift.

By following these tips, forklift operators can navigate extreme weather conditions with confidence and minimize the risk of accidents or injuries. At HCO Innovations, we understand the importance of safe and efficient warehouse operations. Our expertise in warehouse optimization and forklift fleet management can help businesses improve their operational efficiency and reduce material handling costs. With comprehensive services including warehouse layout evaluation, safety assessments, and turnkey maintenance solutions, we are the trusted partner for optimizing warehouse operations. Contact us here to learn more about how HCO Innovations can help your business thrive in any weather condition.