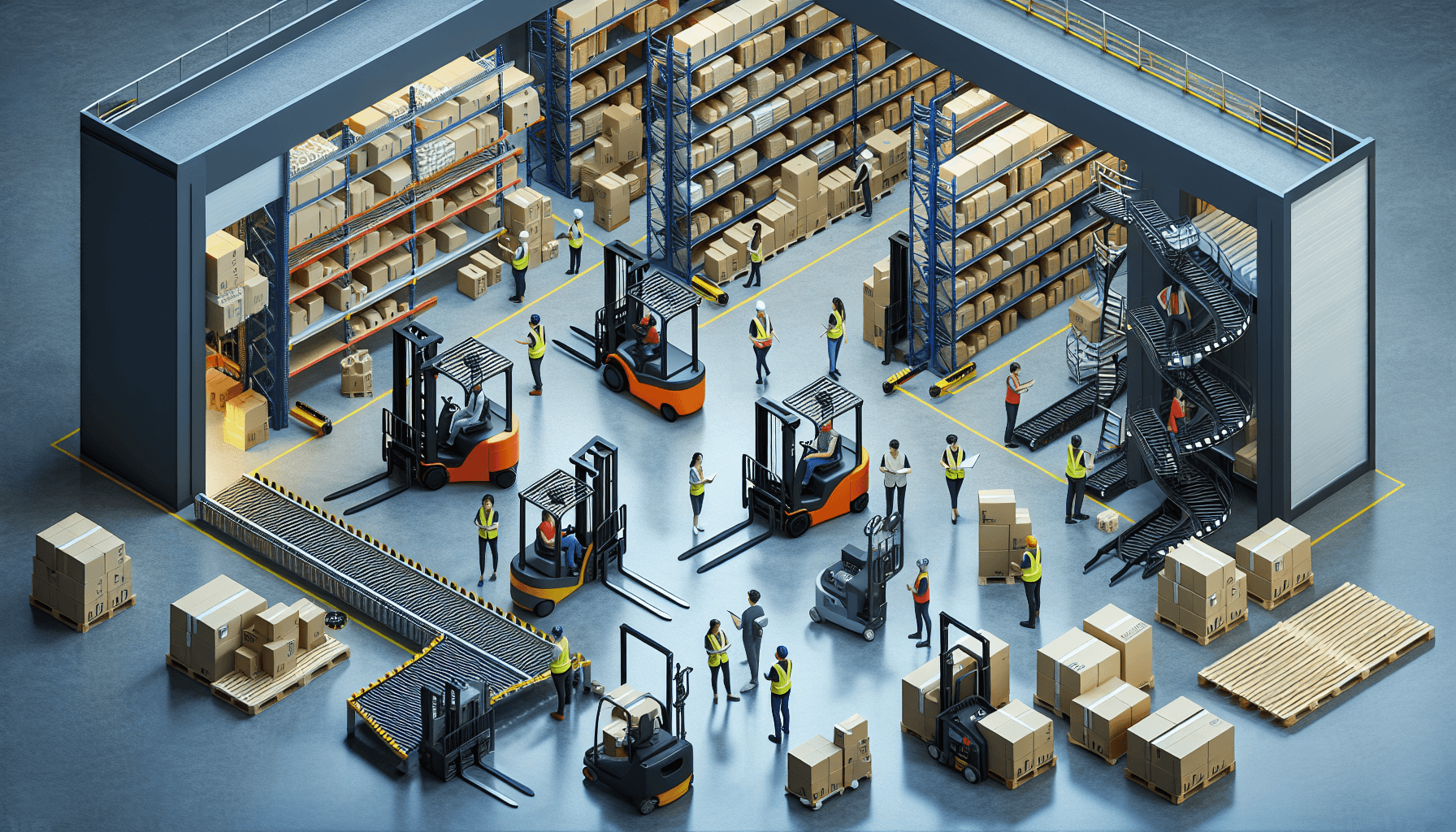

Are you looking to optimize your warehouse operations? One of the key strategies to achieve this is by implementing the right material handling equipment. Having the appropriate equipment can significantly improve safety, productivity, efficiency, and cost-effectiveness within your warehouse. In this article, we will explore the importance of choosing the right material handling equipment and how it can help you optimize your warehouse operations.

The Importance of Material Handling Equipment

Material handling equipment plays a crucial role in warehouse operations. It involves the movement, storage, control, and protection of materials and products throughout the facility. The right equipment can streamline processes, reduce manual labor, prevent workplace injuries, and enhance overall operational efficiency.

When choosing material handling equipment for your warehouse, it is essential to consider factors such as the nature of your products, facility layout, storage requirements, and load capacities. This will ensure that you select equipment that is best suited for your specific needs.

Types of Material Handling Equipment

There are various types of material handling equipment available, each designed for specific tasks and operations within the warehouse. Here are some of the commonly used equipment:

- Forklifts: Forklifts are versatile machines that can lift and move heavy loads. They are ideal for stacking palletized products, loading and unloading trucks, and transporting materials within the warehouse. Forklifts come in different sizes and capacities to cater to different requirements.

- Pallet Jacks: Pallet jacks are manual or electric-powered devices used for lifting and moving pallets. They are perfect for smaller warehouses or areas with limited space. Pallet jacks are cost-effective and easy to maneuver.

- Conveyors: Conveyors are automated systems used for moving materials between different areas of the warehouse. They are efficient for transporting goods over long distances and can be customized to suit specific requirements.

- Shelving and Racking Systems: Shelving and racking systems provide storage solutions for organizing and optimizing warehouse space. They include pallet racking, cantilever racks, and mezzanines. Proper storage systems can maximize vertical space and improve inventory management.

- Automated Guided Vehicles (AGVs): AGVs are robotic vehicles programmed to navigate and transport materials within the warehouse. They can operate autonomously, reducing the need for manual intervention and improving efficiency.

Benefits of Optimal Material Handling Equipment

Investing in the right material handling equipment comes with several benefits for your warehouse operations:

- Increased Efficiency: By using the appropriate equipment, you can streamline processes and improve workflow, leading to faster and more efficient operations.

- Enhanced Safety: Material handling equipment such as forklifts and conveyors are designed to minimize the risk of workplace injuries by providing proper handling and transportation of materials.

- Cost Savings: Optimized material handling equipment can help reduce labor costs, minimize errors in handling, and prevent product damages, ultimately resulting in cost savings for your warehouse.

- Improved Space Utilization: With effective storage solutions, you can maximize the use of available space and efficiently organize your inventory.

- Flexibility and Scalability: Investing in versatile equipment allows for adaptability to changing business needs, allowing you to scale your operations as your business grows.

Choosing the Right Material Handling Equipment

When selecting material handling equipment for your warehouse, it’s crucial to consider the specific needs of your operations. Here are some factors to consider:

- Product Characteristics: Consider the weight, size, shape, and fragility of the products you handle regularly. This will help determine the type of equipment required.

- Warehouse Layout: Analyze your warehouse layout to identify any constraints such as narrow aisles, low ceiling heights, or limited floor space. This information will help select equipment that can operate effectively within your facility.

- Integration with Existing Systems: If you already have automated systems or software in place, choose equipment that can integrate seamlessly with your existing infrastructure.

- Capacity and Durability: Ensure that the equipment you choose can handle the expected workload, withstand the demands of your operations, and provide a long service life.

- Maintenance and Service: Consider the availability of spare parts and the level of support provided by equipment manufacturers or vendors.

By carefully evaluating these factors and working with a trusted provider of warehouse optimization solutions like HCO Innovations, you can make informed decisions about the right material handling equipment for your warehouse.

Implementing the right material handling equipment is a vital step towards optimizing your warehouse operations. It improves efficiency, safety, and cost-effectiveness while allowing for growth and scalability. Take the time to analyze your warehouse requirements and invest in the appropriate equipment to enhance your productivity and overall success.

To learn more about how HCO Innovations can help you optimize your warehouse operations with the right material handling equipment, visit our Material Handling Equipment Management page.