In today’s fast-paced and highly demanding warehouse environments, workplace safety is of utmost importance. The focus on preventing workplace injuries and ensuring the well-being of employees is a top priority for warehouse managers. One critical aspect of achieving optimal safety in the warehouse is the effective management of Material Handling Equipment (MHE).

The Importance of Material Handling Equipment

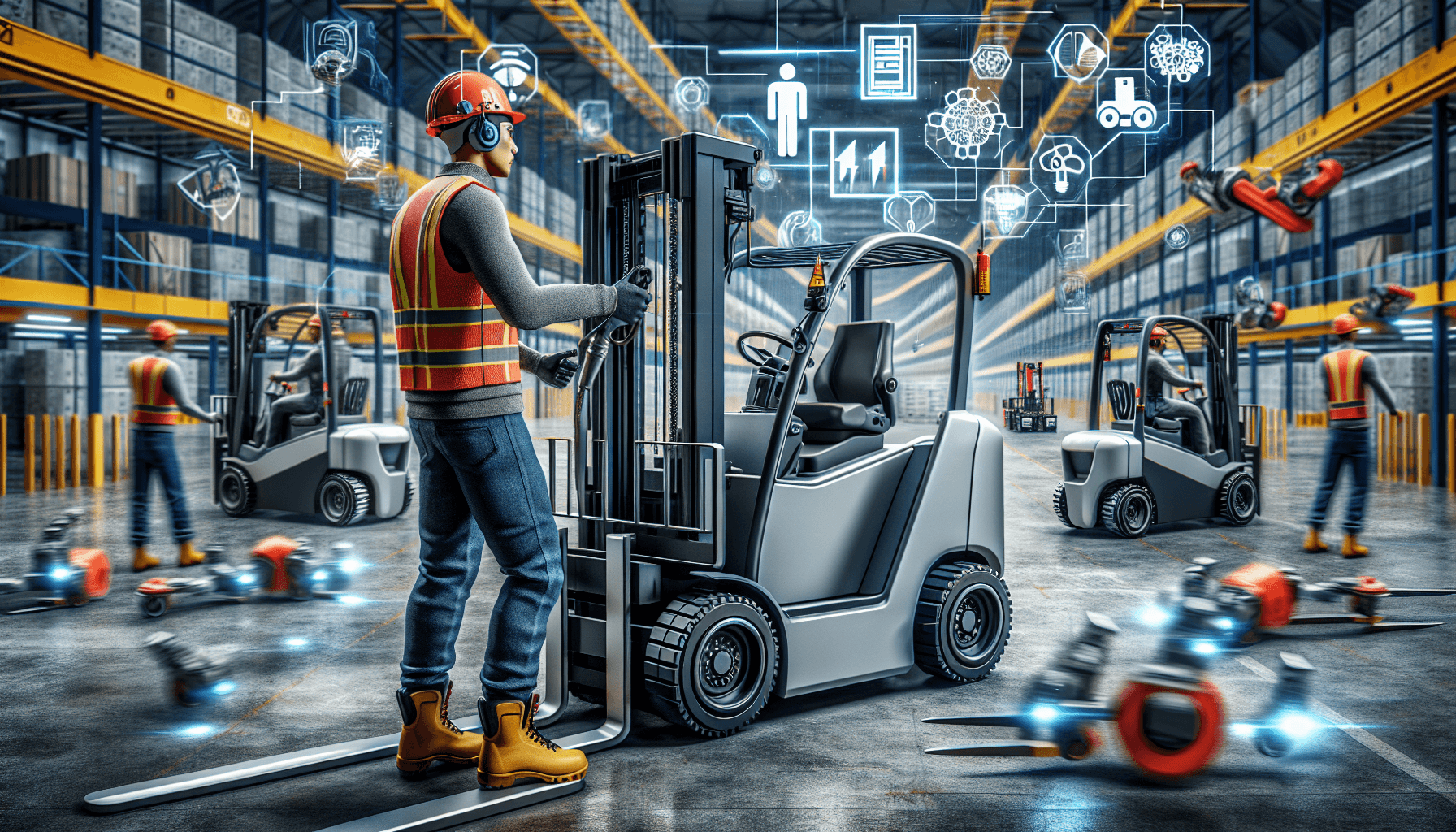

Material Handling Equipment plays a vital role in warehouse operations. These specialized tools and machinery are designed to aid in the movement, storage, and control of materials and products. From forklifts and pallet jacks to conveyors and automated guided vehicles (AGVs), MHE significantly optimizes warehouse efficiency and productivity.

However, the use of MHE comes with inherent risks. Accidents and injuries can occur if proper safety measures are not implemented. This is where HCO Innovations comes in, offering comprehensive warehouse optimization solutions that provide effective MHE management.

The Role of MHE in Reducing Workplace Injuries

MHE technology, when properly utilized and managed, can greatly contribute to the reduction of workplace injuries. Here are some key ways in which MHE plays a vital role in improving safety:

- Ergonomics: Material handling equipment is built with ergonomic design principles in mind. Ergonomics focuses on maximizing efficiency and minimizing strain on the human body. By using ergonomically designed MHE, such as lift tables with adjustable height settings or pallet jacks with comfortable handles, workers can perform their tasks with reduced physical stress. This, in turn, reduces the risk of musculoskeletal disorders and injuries caused by repetitive motions or heavy lifting.

- Automation: Automated MHE, such as AGVs and conveyor systems, significantly reduces the need for manual labor and repetitive tasks. This minimizes the exposure of workers to potentially hazardous situations, such as lifting heavy loads or operating machinery in cramped spaces. By automating these processes, workers can be reassigned to less physically demanding tasks, leading to a decrease in workplace injuries.

- Safety Features: Modern MHE is equipped with advanced safety features to enhance worker protection. For instance, forklifts may have proximity sensors and anti-collision systems to prevent accidents and injuries. Pallet jacks may have emergency stop buttons and stability controls to ensure stability during transportation. By utilizing MHE with these built-in safety features, the risk of workplace injuries can be significantly reduced.

- Training and Education: Effective MHE management includes comprehensive training programs for employees on the proper usage and safety protocols of handling equipment. Warehouse operators should provide clear instructions and regular training sessions for equipment operation, maintenance, and safe working practices. This ensures workers are knowledgeable and aware of potential hazards, leading to a safer work environment.

By implementing effective MHE management practices, warehouse operators can create a safer and more efficient working environment. HCO Innovations offers warehouse optimization solutions that encompass MHE management by providing technologies, training, and expertise to mitigate workplace injuries.

If you’re interested in enhancing safety and reducing workplace injuries in your warehouse, consider the comprehensive solutions offered by HCO Innovations. Learn more about their Material Handling Equipment Management services here.

Remember, the well-being of your employees is crucial, and investing in proper MHE management is a proactive step towards a safer and more productive warehouse.