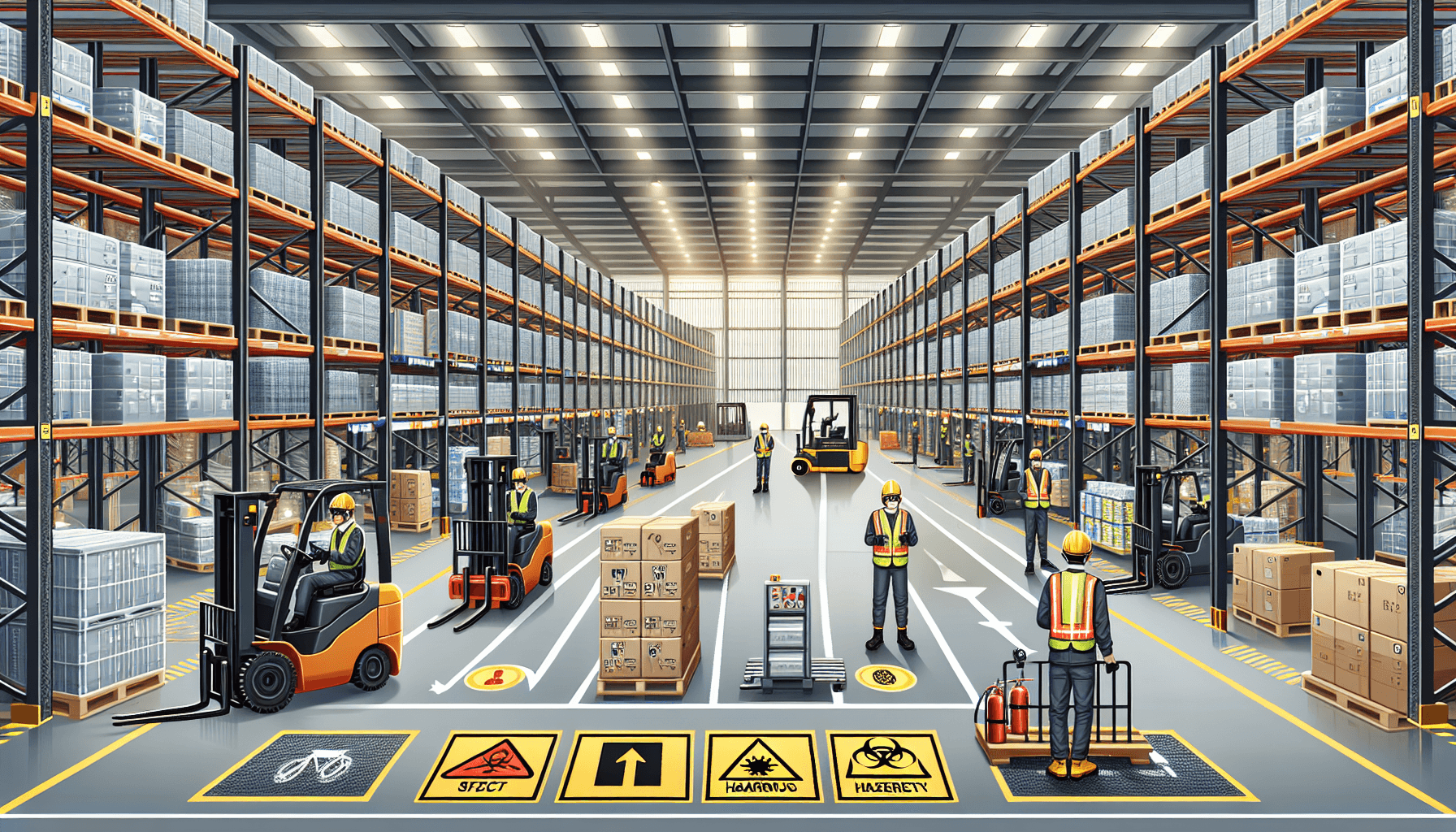

If you are involved in handling hazardous materials in your warehouse, it is crucial to prioritize safety and efficiency. Properly optimizing your material handling equipment (MHE) can significantly enhance both productivity and safety within your operations. In this article, we will discuss some valuable strategies and best practices to optimize MHE specifically for hazardous material handling.

1. Conduct a Hazard Assessment

Before diving into any optimization efforts, it is important to identify and understand the specific hazards associated with your materials. Conducting a thorough hazard assessment will help you identify potential risks and develop strategies to mitigate them. Assess factors such as chemical properties, flammability, toxicity, and reactive properties to determine the appropriate handling and storage methods.

2. Invest in Suitable MHE

Using the right material handling equipment is fundamental to safe and efficient operations. Make sure your equipment is designed to handle hazardous materials and is compliant with relevant safety standards. Consider investing in specialized equipment such as explosion-proof forklifts, flame-resistant storage containers, or leak-proof drum handlers. HCO Innovations offers a wide range of material handling equipment management solutions that can help you identify the right equipment for your specific needs. Learn More Here.

3. Implement Proper Training and Safety Protocols

Proper training and strict adherence to safety protocols are essential when handling hazardous materials in the warehouse. Ensure that all employees involved in material handling receive comprehensive training on the safe handling, storage, and disposal of hazardous materials. Emphasize the importance of using personal protective equipment (PPE) and following established safety procedures at all times. Regularly reinforce and update safety protocols to ensure ongoing compliance.

4. Optimize Material Storage and Organization

Efficient organization and storage of hazardous materials are crucial for workplace safety and productivity. Implement a systematic approach to categorizing, labeling, and storing hazardous materials in a way that minimizes the risk of accidents or cross-contamination. Utilize clearly marked storage areas, safety cabinets, and containment systems to ensure proper segregation and easy accessibility. Regularly audit and update storage arrangements to maintain efficiency and compliance.

5. Improve Workflow and Process Efficiency

Streamlining your material handling processes can significantly impact overall efficiency and reduce the risk of accidents. Analyze your workflow and identify areas for improvement. This could include optimizing routes for material movement, implementing automation or robotic solutions for repetitive tasks, and utilizing barcode or RFID technology for accurate inventory tracking. Continuous improvement will help minimize human error and ensure maximum efficiency within your operations.

6. Regular Maintenance and Inspection

Regular maintenance and inspections of your material handling equipment are crucial for safe and efficient operations. Develop a preventive maintenance program that includes regular inspections, cleaning, and repair to identify and address potential issues before they result in accidents or breakdowns. Encourage employees to report any equipment malfunctions or safety concerns promptly to prevent further risks.

7. Stay Compliant with Regulations

Compliance with relevant regulations is non-negotiable when handling hazardous materials. Stay updated with federal, state, and local regulations regarding hazardous material handling. Regularly review and assess your practices to ensure compliance with labeling, reporting, and storage requirements. Engage with expert consultants or agencies to stay informed about any changes in regulations and adapt your procedures accordingly.

Conclusion

Optimizing material handling equipment for hazardous material handling requires a holistic approach that prioritizes safety, efficiency, and compliance. By conducting a hazard assessment, investing in suitable MHE, implementing proper training and safety protocols, optimizing storage and organization, improving workflow and processes, conducting regular maintenance and inspections, and staying compliant with regulations, you can ensure a safe and productive environment in your warehouse. Remember, HCO Innovations is here to help you with their material handling equipment management solutions. Learn more here.