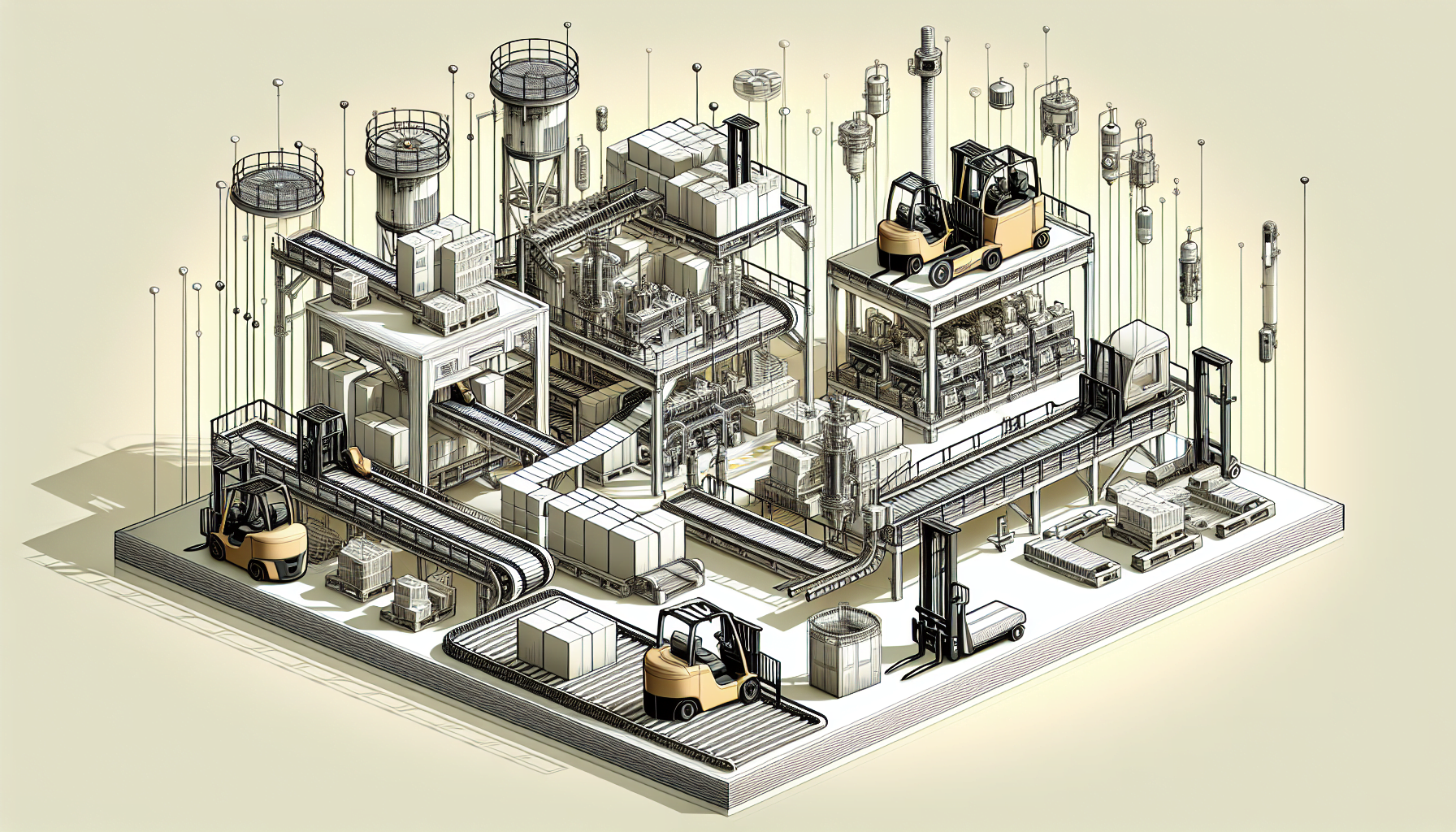

When it comes to achieving operational excellence in a warehouse environment, one key factor that cannot be overlooked is the role of Material Handling Equipment (MHE). MHE refers to a wide range of tools, machinery, and vehicles that are used to move, store, and handle materials within a warehouse or distribution center. By optimizing the use of MHE, companies can significantly improve the safety, productivity, efficiency, and overall performance of their warehouse operations.

The Importance of MHE in Warehouse Operations

MHE plays a crucial role in warehouse operations as it enables the smooth movement and handling of materials, both incoming and outgoing. It allows for efficient and timely order fulfillment, minimizes product damage, and ensures accurate inventory control. Here are some key reasons why MHE is important for achieving operational excellence:

- Increased Productivity: Utilizing MHE such as forklifts, pallet jacks, and conveyor systems can significantly increase the productivity of warehouse operations. These tools enable workers to move materials quickly and efficiently, reducing the time required for manual handling and transportation.

- Enhanced Safety: Warehouse environments can be inherently hazardous, with heavy materials, high shelves, and busy traffic areas. By utilizing MHE, companies can improve safety by reducing the risk of accidents and injuries caused by manual handling. MHE is designed with safety features such as ergonomic controls, lifting mechanisms, and stability systems to ensure safe operations.

- Optimized Space Utilization: MHE can help optimize the use of space within a warehouse. For example, using vertical lift modules or automated storage and retrieval systems allows for efficient utilization of vertical space, reducing the need for expansive floor space. This can result in cost savings and improved efficiency.

- Accurate Inventory Management: MHE such as barcode scanners and RFID systems can be integrated into warehouse operations to track and manage inventory in real-time. This ensures accurate inventory counts, reduces errors, and enables efficient order fulfillment.

- Cost-Effective Operations: Investing in the right MHE solutions can lead to significant cost savings in the long run. By improving efficiency and reducing labor-intensive tasks, companies can lower operational costs and achieve a higher return on investment.

The role of MHE in achieving operational excellence cannot be overstated. It enables companies to streamline processes, improve customer satisfaction, and stay competitive in today’s fast-paced business landscape. However, it is important for companies to choose the right MHE solutions that are tailored to their specific needs and requirements.

HCO Innovations: Your Partner in Warehouse Optimization

HCO Innovations is a leading provider of warehouse optimization solutions, specializing in enhancing safety, productivity, efficiency, and cost-effectiveness within warehouse operations. With a comprehensive range of MHE management services, HCO Innovations helps companies optimize their material handling processes to achieve operational excellence.

HCO Innovations offers personalized solutions tailored to the unique needs of each client. Their team of experts conducts a thorough analysis of the client’s warehouse operations, identifies areas for improvement, and recommends the most suitable MHE solutions. Whether it’s implementing automated systems, optimizing layout and flow, or integrating advanced technologies, HCO Innovations ensures that every aspect of the warehouse operation is optimized for maximum efficiency.

Furthermore, HCO Innovations provides ongoing support and maintenance services to ensure the continuous performance and reliability of the MHE solutions. Their team is available for training, troubleshooting, and equipment maintenance to minimize downtime and maximize productivity.

By partnering with HCO Innovations, companies can unlock the full potential of their warehouse operations, achieving operational excellence and gaining a competitive edge in the market.

Interested in learning more about how HCO Innovations can help optimize your warehouse operations through material handling equipment management? Visit HCO Innovations today!