Warehouses are bustling hubs of activity, with workers, machinery, and goods constantly moving around. While this dynamic environment is necessary for efficient operations, it also poses certain risks, especially when it comes to forklift-pedestrian collisions. These accidents can result in severe injuries or even fatalities. Therefore, it is crucial for warehouse managers to prioritize safety and implement measures to prevent such incidents.

The Importance of Preventing Forklift-Pedestrian Collisions

Forklift-pedestrian collisions are a significant concern in warehouse operations. According to the Occupational Safety and Health Administration (OSHA), forklift accidents account for a significant number of workplace fatalities each year. These accidents can cause serious injuries and result in substantial financial costs for businesses.

Preventing forklift-pedestrian collisions is crucial for several reasons:

- Worker Safety: The well-being of employees should always be a top priority for any warehouse. By preventing collisions, you can minimize the risk of injuries or fatalities, creating a safer working environment.

- Reduced Costs: Workplace accidents can lead to medical expenses, legal liabilities, and higher insurance premiums. By preventing collisions, you can avoid these unnecessary costs and allocate resources more effectively.

- Enhanced Productivity: Accidents can disrupt operations, leading to delays and decreased productivity. By implementing measures to prevent collisions, you can maintain a smooth workflow and maximize efficiency.

Effective Strategies for Preventing Forklift-Pedestrian Collisions

Implementing the following strategies can significantly reduce the risk of forklift-pedestrian collisions:

1. Employee Training and Awareness

Proper training is essential for all individuals working in the warehouse, including both forklift operators and pedestrians. Employees should be trained on the safe operation of forklifts and the importance of following designated walkways and safety protocols.

Regular refresher courses and awareness campaigns can help reinforce safety practices and keep employees vigilant. It is crucial to educate workers about the potential hazards associated with forklifts and the importance of staying alert and attentive at all times.

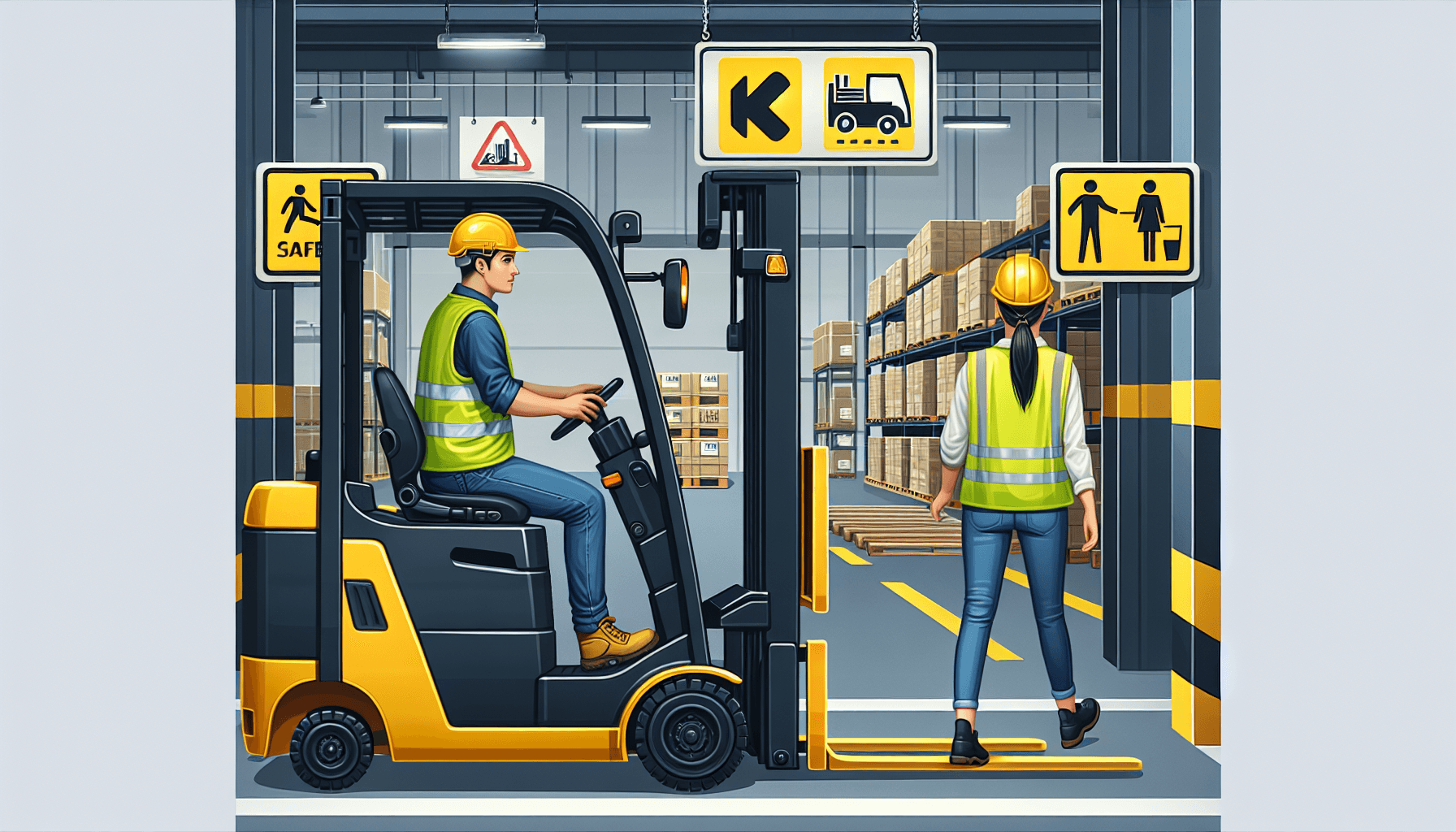

2. Clear Signage and Markings

Clear and prominently displayed signage and markings are essential for guiding both forklift operators and pedestrians. Visual cues, such as floor markings, arrows, and signs indicating pedestrian-only zones or forklift traffic, can help reduce the risk of collisions.

Using contrasting colors and highly visible signage will make it easier for individuals to identify their respective areas and follow the designated routes. It is also important to regularly inspect and maintain these signage and markings to ensure their visibility and effectiveness.

3. Separate Pedestrian and Forklift Traffic

Separating pedestrian and forklift traffic is a critical measure to prevent collisions. Designated walkways and paths should be created, ensuring that pedestrians have the means to move around the warehouse safely, away from forklifts.

Physical barriers, such as guardrails or barriers, can be installed to further enhance the separation between pedestrians and forklifts. By creating designated areas for each group, the risk of accidental contact can be significantly reduced.

4. Implement Forklift Speed Limits

Setting and enforcing speed limits for forklifts is an effective way to promote safer operations and prevent collisions. High speeds increase the risk of accidents and reduce the operator’s ability to react promptly to unexpected situations.

By implementing speed limits and closely monitoring forklift speeds, you can create a safer environment for both forklift operators and pedestrians. It is important to regularly communicate and enforce these speed limits to ensure compliance.

5. Use Forklift-Pedestrian Detection Systems

One of the most advanced and effective measures to prevent forklift-pedestrian collisions is the use of forklift-pedestrian detection systems. These systems utilize sensors and advanced technology to detect the presence of pedestrians in the vicinity of forklifts.

HCO Innovations offers a state-of-the-art Forklift-Pedestrian Detection System that provides real-time alerts to forklift operators when pedestrians are in close proximity. This eliminates blind spots and significantly reduces the risk of accidental collisions.

By investing in such innovative solutions, warehouses can not only enhance safety but also improve productivity and reduce costly accidents.

Conclusion

Forklift-pedestrian collisions pose a significant risk in warehouse operations. Implementing effective strategies such as employee training, clear signage, separate traffic routes, and the use of advanced technology like forklift-pedestrian detection systems can greatly mitigate these risks.

Warehouses must prioritize safety and embrace measures that prioritize accident prevention. By doing so, they can create a secure working environment, reduce costs, and enhance overall productivity. Preventing forklift-pedestrian collisions should be a priority for any warehouse that values the well-being of its employees and the success of its operations.

What are the main causes of forklift-pedestrian collisions in warehouses?

The main causes of forklift-pedestrian collisions in warehouses include lack of communication between forklift operators and pedestrians, limited visibility, excessive speed, failure to yield, and inadequate training.

How can I improve communication between forklift operators and pedestrians in a warehouse?

To improve communication between forklift operators and pedestrians, it is important to establish clear hand signals and use designated communication devices such as two-way radios or headsets. Implementing a system of communication can help to avoid misunderstandings and enhance safety.

What measures can be taken to enhance visibility and prevent collisions?

To enhance visibility and prevent collisions, it is recommended to keep work areas well-lit, install mirrors at corners and blind spots, use warning signs and signals, and ensure clear lines of sight by keeping aisles and pathways free from obstructions.

How can excessive speed contribute to forklift-pedestrian collisions?

Excessive speed can contribute to forklift-pedestrian collisions by reducing the operator's ability to react to unexpected hazards or pedestrians in their path. It is crucial for forklift operators to adhere to safe speed limits and adjust their speed according to the conditions of the warehouse.

What does it mean for a forklift operator to "yield" to pedestrians?

When a forklift operator is required to "yield" to pedestrians, it means they should give the right of way to pedestrians and allow them to pass safely. This includes slowing down or stopping when necessary and always being aware of pedestrians in the vicinity of the forklift.

What role does training play in preventing forklift-pedestrian collisions?

Proper training is crucial in preventing forklift-pedestrian collisions. Forklift operators should be trained on the safe operation of forklifts, understanding the importance of communication and visibility, following warehouse safety protocols, and being aware of potential hazards and how to avoid them.

Are there any specific safety guidelines for pedestrians in warehouses?

Yes, there are specific safety guidelines for pedestrians in warehouses. Pedestrians should always be alert and aware of their surroundings, avoid walking in forklift traffic lanes, use designated pedestrian pathways, make eye contact with forklift operators before crossing their path, and wear high-visibility clothing to increase their visibility to forklift operators.

What should I do if I witness an unsafe situation involving a forklift and a pedestrian in a warehouse?

If you witness an unsafe situation involving a forklift and a pedestrian, it is important to immediately report it to a supervisor or the designated safety personnel in your workplace. Prompt reporting can help prevent accidents and ensure that proper measures are taken to address the issue.

Are there any technological solutions that can help prevent forklift-pedestrian collisions?

Yes, there are technological solutions available to help prevent forklift-pedestrian collisions. Some examples include proximity sensors that sound alarms when pedestrians are too close to the forklift, speed limiters that restrict the maximum speed of forklifts, and cameras or radar systems that provide additional visibility for the operator.

Creating a Culture of Safety: Promoting Workplace Wellness in Warehouses.

Creating a Culture of Safety: Promoting Workplace Wellness in Warehouses.

The Importance of Workplace Safety

Warehouse operations can be fast-paced and demanding, with workers handling heavy machinery, equipment, and inventory on a daily basis. It is crucial for companies to prioritize workplace safety to ensure the well-being of their employees and the overall efficiency of their operations. Implementing a culture of safety not only reduces the risk of accidents and injuries but also fosters employee morale and productivity.

At HCO Innovations, we understand the significance of workplace safety in warehouse environments. As a leading management consulting firm specializing in warehouse optimization and forklift fleet management, we have helped numerous companies establish robust safety protocols and create a culture of safety within their organizations.

The Basics of Workplace Safety

Workplace safety begins with a comprehensive understanding of potential hazards and the implementation of preventative measures. Here are some foundational elements of workplace safety in a warehouse setting:

- Training and Education: Proper training should be provided to all employees on the safe operation of forklifts, machinery, and equipment. Regular safety meetings and ongoing education can help reinforce safe practices and raise awareness about potential hazards.

- Clear Communication: Effective communication is crucial for maintaining safety in a warehouse. Clear signage, labels, and floor markings help guide employees and alert them to potential dangers. Additionally, frequent communication between management and employees fosters an open dialogue about safety concerns and encourages reporting of any hazardous conditions.

- Proper Equipment Maintenance: Regular inspections and maintenance of machinery and equipment are essential for preventing malfunctions and minimizing the risk of accidents. Prompt repairs and replacements should be carried out to ensure safe and efficient operations.

- Proactive Safety Audits: Regular safety audits and inspections should be conducted to identify potential hazards and areas for improvement. This proactive approach helps mitigate risks and ensures compliance with safety regulations.

Building a Culture of Safety

Creating a culture of safety goes beyond implementing safety protocols; it involves embedding safety awareness into the fabric of the organization. Here are some strategies to promote workplace wellness and foster a culture of safety:

- Leadership Commitment: Safety starts at the top. Management should lead by example and prioritize safety as a core value. When leaders demonstrate a genuine commitment to safety, it sets a positive tone for the entire organization.

- Employee Involvement: Empowering employees to actively participate in safety programs and decision-making processes promotes a sense of ownership and accountability. Regular safety training and open channels of communication allow employees to provide feedback and contribute to a safer work environment.

- Recognition and Incentives: Recognizing and rewarding employees for their commitment to safety reinforces the importance of safe practices. Incentives such as bonuses, awards, or additional training opportunities can motivate employees to prioritize safety.

- Continuous Improvement: Safety should be an ongoing effort. Regularly assess safety protocols, identify areas for improvement, and implement changes accordingly. Encouraging feedback from employees and incorporating their suggestions demonstrates a commitment to continuous improvement.

The Benefits of Prioritizing Workplace Safety

Investing in workplace safety not only protects employees but also yields significant benefits for businesses. Here are some of the key advantages:

- Reduced Accidents and Injuries: By implementing proper safety measures, companies can significantly reduce the occurrence of workplace accidents and injuries. This leads to lower healthcare costs, decreased absenteeism, and improved productivity.

- Cost Savings: Preventing accidents and injuries also translates into cost savings. Companies can avoid potential legal liabilities, workers' compensation claims, and unplanned expenses associated with accidents. Additionally, businesses with a strong safety record may benefit from lower insurance premiums.

- Improved Employee Morale and Retention: Prioritizing workplace safety demonstrates a company's commitment to the well-being of its employees. This fosters a positive work environment, enhances employee morale, and increases employee retention rates. Employees who feel safe and valued are more likely to remain loyal and productive.

- Enhanced Reputation: Companies known for their commitment to workplace safety often attract top talent and enjoy a positive reputation within their industry. Customers, partners, and stakeholders are more likely to trust and engage with businesses that prioritize the health and safety of their employees.

HCO Innovations: Your Partner in Warehouse Optimization

At HCO Innovations, we understand the critical role that workplace safety plays in optimizing warehouse operations. Our comprehensive services, including warehouse layout evaluation, safety assessments, and turnkey maintenance solutions, are designed to help companies reduce material handling costs and achieve operational efficiency while promoting a culture of safety.

By leveraging advanced cost-tracking software and employing a collaborative "boots on the ground" approach, we provide tailored solutions that consistently deliver exceptional return on investment. Our team of experts works closely with clients across industries such as distribution, manufacturing, and food processing to identify safety gaps, develop customized safety protocols, and implement best practices.

When it comes to promoting workplace wellness and creating a culture of safety, HCO Innovations is your trusted partner. Contact us today at https://www.hcoinnovations.com/ to learn more about our services and how we can help optimize your warehouse operations while prioritizing the well-being of your employees.