Warehouse pedestrian safety is a critical concern for any facility. With the constant movement of forklifts, pallet jacks, and other machinery, pedestrians can be at risk of accidents and injuries. That’s why it’s crucial for warehouse operators to implement effective safety measures to protect their employees and visitors.

The Importance of Floor Markings in Warehouse Pedestrian Safety

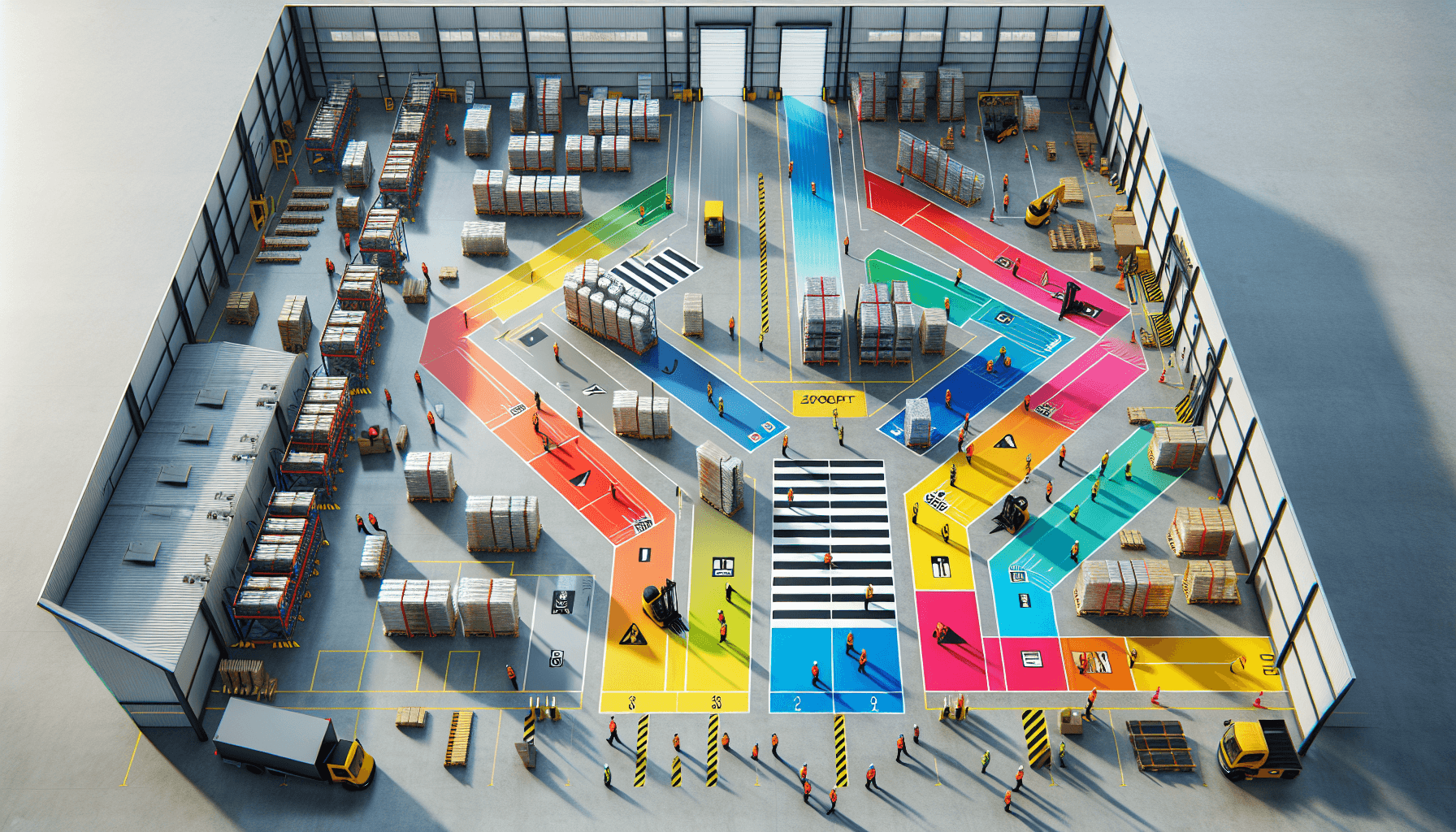

One effective way to improve warehouse pedestrian safety is through the use of floor markings. Floor markings serve as visual cues and guide pedestrians on safe paths, helping to prevent accidents and promote a culture of safety within the facility.

Here are some key reasons why floor markings are essential for warehouse pedestrian safety:

1. Clearly Defined Walkways

Properly marked walkways provide pedestrians with a clear and designated path to follow while navigating through the warehouse. By marking the floor with bold, colorful lines or arrows, warehouse operators can guide employees and visitors to stay within these designated areas, away from any potentially hazardous zones.

With clearly defined walkways, pedestrians are less likely to stray into forklift traffic areas or collide with machinery or storage equipment. This helps to reduce the risk of accidents and ensures a safer working environment for everyone.

2. Hazard Identification

Aside from marking walkways, floor markings can also be used to identify various hazards within the warehouse. These hazards may include areas with low clearance, potential tripping hazards, or restricted access zones. By using different colors or patterns, warehouse operators can effectively communicate to pedestrians where they need to exercise caution.

For example, bright yellow floor markings can be used to indicate areas with low clearance, warning pedestrians to watch their heads or avoid those zones altogether. Similarly, red markings can be used to alert pedestrians to hazardous equipment or machinery areas, prompting them to take extra care.

3. Segregation of Pedestrian and Vehicle Traffic

One of the most significant challenges in maintaining warehouse pedestrian safety is managing the interaction between pedestrians and moving vehicles, such as forklifts. By using floor markings, warehouse operators can clearly separate pedestrian and vehicle traffic, minimizing the chances of accidents.

For instance, a clearly marked pedestrian walkway can be established parallel to a designated forklift route. This ensures that pedestrians have their own safe space, away from the path of moving vehicles. Additionally, floor markings can be used to alert pedestrians of intersections, reminding them to look out for approaching forklifts or other vehicles.

4. Emergency Exits and Escape Routes

In the event of an emergency, having clearly marked floorings can be a lifesaver. Floor markings can guide pedestrians to the nearest emergency exits, evacuation routes, and assembly points. Properly marked exit paths and emergency escape routes help to prevent panic and confusion during critical situations.

Additionally, floor markings can also indicate the locations of fire extinguishers, emergency showers, and other safety equipment. This ensures that during an emergency, employees and visitors can quickly locate and access the necessary resources.

It’s worth noting that floor markings should be regularly maintained and kept visible at all times. Faded or obscured markings can confuse pedestrians and lead to accidents. Warehouse operators should have a schedule for inspecting and refreshing the floor markings to ensure their effectiveness in enhancing pedestrian safety.

In conclusion, floor markings play a crucial role in improving warehouse pedestrian safety. They provide clearly defined walkways, identify hazards, segregate pedestrian and vehicle traffic, and guide people during emergencies. Implementing floor markings in warehouses contributes to a safer working environment and reduces the risk of accidents and injuries.

If you’re interested in learning more about advanced warehouse safety solutions, including forklift pedestrian detection systems, check out our website for more information.