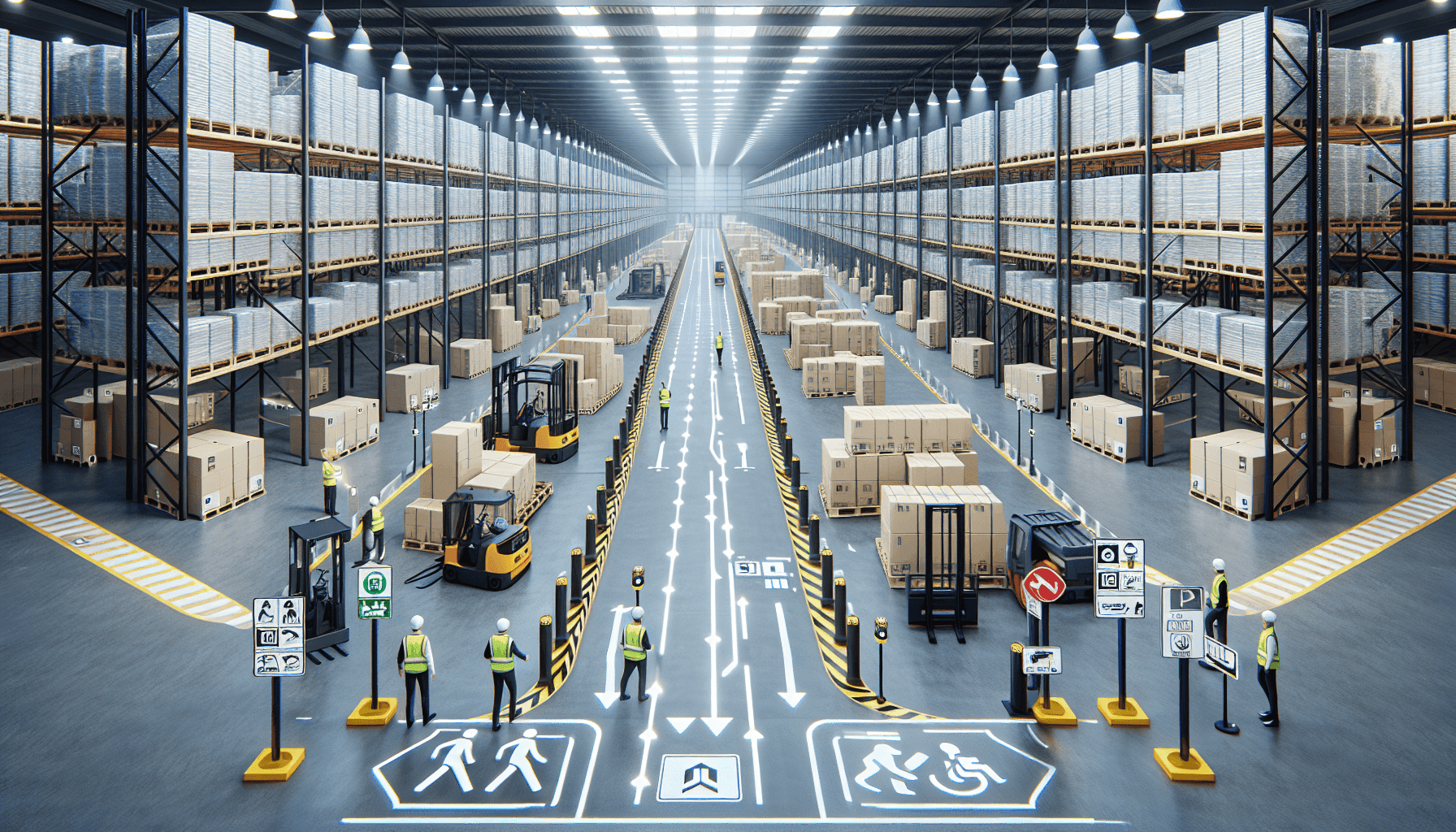

Warehouses are busy and bustling places, with numerous activities and operations taking place simultaneously. From the movement of forklifts and pallet jacks to the stacking and storage of goods, there are plenty of potential hazards that can put pedestrian safety at risk. One effective solution to protect warehouse pedestrian walkways and prevent accidents is the use of safety barriers.

The Importance of Protecting Warehouse Pedestrian Walkways

Warehouse pedestrian walkways are essential for the safe movement of workers within the facility. These walkways provide designated paths for employees to travel, ensuring they are not exposed to the risks associated with forklift traffic or other potentially hazardous areas of the warehouse. By safeguarding these walkways, employers can significantly reduce the likelihood of accidents, injuries, and even fatalities.

According to the Occupational Safety and Health Administration (OSHA), forklift-related accidents are a leading cause of injuries in warehouses. These accidents often occur when pedestrians inadvertently cross paths with forklifts or when they are not aware of their surroundings. By implementing safety barriers along pedestrian walkways, employers can create a physical barrier that separates workers from forklift traffic, reducing the potential for accidents.

Moreover, safety barriers act as a visual reminder to both pedestrians and forklift operators to exercise caution and remain aware of their surroundings. This increased awareness can help prevent dangerous situations and encourage a safer working environment for everyone in the warehouse.

The Role of Safety Barriers in Warehouse Pedestrian Safety

Safety barriers play a crucial role in protecting warehouse pedestrian walkways. These barriers are designed to create a physical separation between pedestrians and moving equipment, such as forklifts. They act as a visual cue to both pedestrians and forklift operators, indicating the areas where pedestrians should walk and ensuring that forklifts stay within their designated paths.

There are several types of safety barriers that can be used to protect warehouse pedestrian walkways:

- 1. Guardrails: Guardrails are a commonly used safety barrier that provides a continuous physical barrier along the edges of pedestrian walkways. They are typically made of durable materials such as steel or aluminum and are designed to withstand impacts from forklifts or other equipment. Guardrails can be customized to fit the specific layout of the warehouse and can be installed at varying heights depending on the level of protection required.

- 2. Bollards: Bollards are short, sturdy posts that are installed at regular intervals to create a protective barrier along pedestrian walkways. They are ideal for areas where a continuous guardrail may not be necessary or practical. Bollards can be fixed or removable, allowing for flexibility in managing access to certain areas of the warehouse.

- 3. Safety gates: Safety gates are used to control access points along pedestrian walkways. They can be installed at entrances, exits, or other areas where pedestrians need to cross paths with forklift traffic. Safety gates can be designed to automatically close after a person passes through, providing an added layer of protection and ensuring that the walkway remains secure.

By strategically placing these safety barriers along warehouse pedestrian walkways, employers can create a well-defined separation between pedestrian and forklift areas. This promotes a safe and organized flow of traffic, reducing the risk of accidents and injuries.

The Benefits of Implementing Safety Barriers

Implementing safety barriers in warehouse pedestrian walkways offers numerous benefits:

- 1. Enhanced safety: Safety barriers provide physical protection and serve as a visual reminder for both pedestrians and forklift operators to follow designated paths and exercise caution. This significantly reduces the risk of accidents and injuries.

- 2. Increased productivity: By separating pedestrian traffic from forklifts, safety barriers prevent disruptions and congestion, allowing workers to move efficiently and complete their tasks without unnecessary delays.

- 3. Improved efficiency: Safety barriers help create a well-organized layout within the warehouse, eliminating the need for pedestrians to navigate around forklifts or other equipment. This streamlines operations and minimizes the chances of obstacles slowing down workflow.

- 4. Cost savings: By reducing accidents and injuries, employers can avoid the financial costs associated with medical expenses, workers’ compensation claims, and potential lawsuits. Additionally, safety barriers can help prevent damage to goods, equipment, and infrastructure, saving on repair or replacement costs.

Overall, the implementation of safety barriers in warehouse pedestrian walkways is an effective solution to protect employees and create a safer working environment. By investing in these proactive measures, employers can demonstrate their commitment to safety and promote a culture of workplace well-being.

In conclusion, safety barriers play a vital role in protecting warehouse pedestrian walkways. They provide a physical separation between pedestrians and forklift traffic, reducing the risk of accidents and injuries. By using guardrails, bollards, and safety gates, employers can create a safe and organized flow of traffic within the warehouse, enhancing productivity and efficiency. Furthermore, the implementation of safety barriers offers benefits such as increased safety, improved productivity, enhanced efficiency, and cost savings. To learn more about warehouse safety solutions, including forklift pedestrian detection systems, visit HCO Innovations.