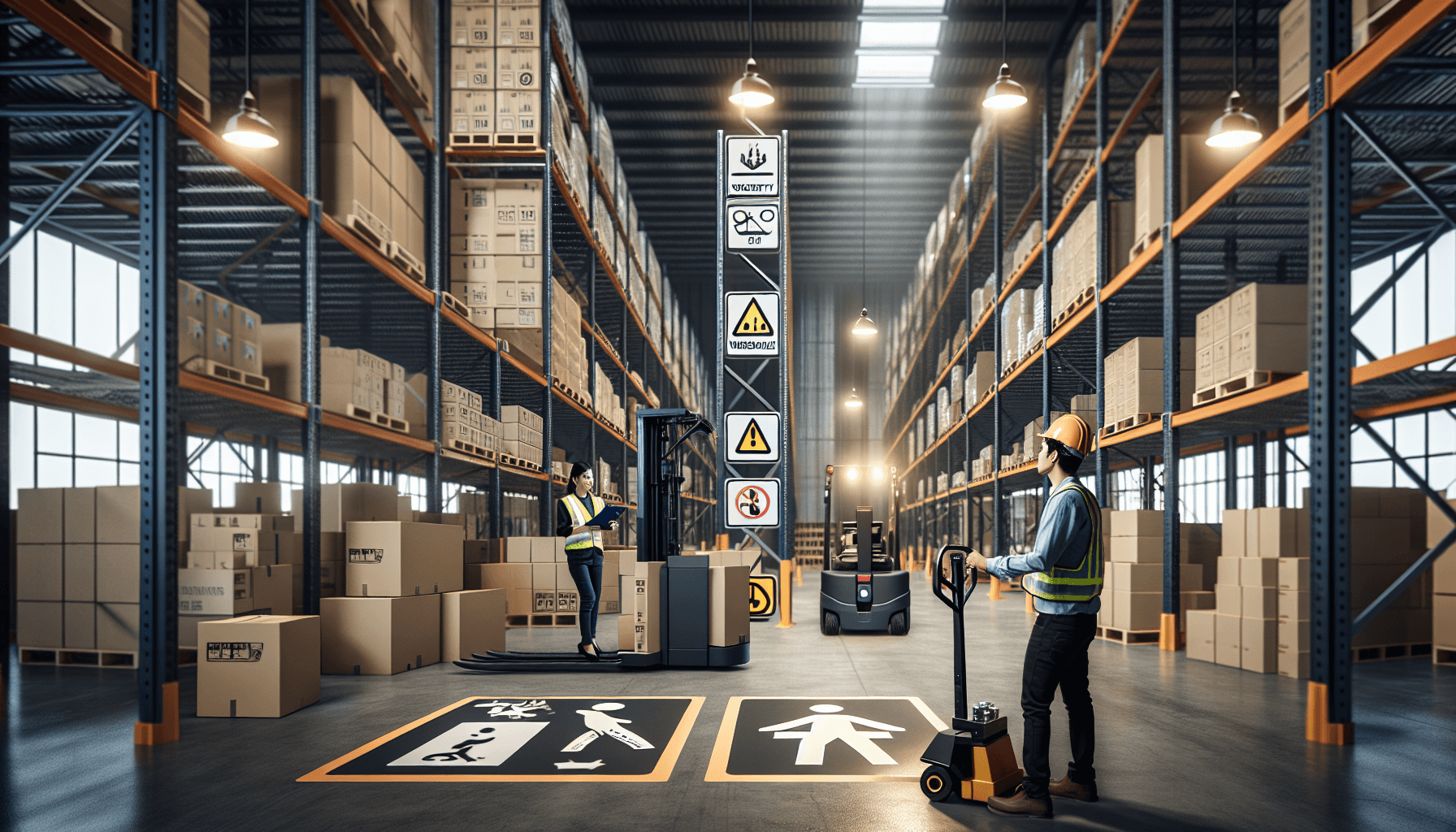

In a bustling warehouse environment, ensuring the safety of all workers is of utmost importance. The constant movement of forklifts and heavy machinery poses a risk to pedestrians who may be on foot within the facility. To address this concern, implementing pedestrian safety signs and symbols is crucial. This article will explore the various benefits that these safety measures bring to warehouses.

Promoting Safety Awareness

The first and foremost benefit of pedestrian safety signs and symbols is the promotion of safety awareness in the warehouse. By placing clear and easily recognizable signs throughout the facility, both pedestrians and forklift operators are constantly reminded to stay vigilant and take necessary precautions. These signs serve as visual reminders to follow proper safety protocols, reducing the likelihood of accidents and injuries.

Moreover, safety symbols, such as those indicating the presence of pedestrians or restricted areas, effectively convey crucial information to all warehouse staff. This includes warning signs about forklift traffic or the direction of pedestrian travel. By understanding and adhering to these symbols, workers can establish a safety-conscious culture within the workplace.

Preventing Accidents and Injuries

One of the primary reasons for implementing pedestrian safety signs and symbols in warehouses is to prevent accidents and injuries. The combination of high-speed forklift traffic and pedestrians in a confined space can lead to disastrous consequences without proper safety measures in place.

By clearly marking pedestrian walkways and indicating areas where forklifts are not permitted, safety signs help segregate foot traffic from vehicle traffic. This reduces the risk of collisions and minimizes the chances of workers being struck by moving machinery. Such preventive measures significantly contribute to injury prevention, creating a safer working environment overall.

In addition to signage, many warehouses also utilize advanced technologies, such as forklift pedestrian detection systems, to further enhance safety. These systems use sensors and cameras to detect pedestrians in the vicinity of forklifts, alerting operators and preventing potential accidents. Implementing such advanced safety solutions alongside appropriate signage adds an extra layer of protection for both pedestrians and forklift operators.

Improving Efficiency and Productivity

While the primary goal of pedestrian safety signs and symbols is to ensure the safety of workers, their implementation also leads to improvements in warehouse efficiency and productivity. When employees feel safe and confident in their working environment, they can perform their tasks with greater focus and efficiency.

Clear signage that designates separate zones for pedestrians and forklift operations helps streamline the flow of traffic within the warehouse. By avoiding unnecessary intersections and minimizing congestion, the overall efficiency of warehouse operations is improved. This not only reduces the risk of accidents but also results in smoother workflow and greater productivity.

Furthermore, properly marked pedestrian paths and designated areas for forklift operations help employees navigate the warehouse more easily. With less time spent on figuring out the correct routes to take, workers can concentrate on their tasks, leading to better time management and increased productivity.

Meeting Regulatory Compliance

Warehouses are subject to various regulations and safety standards, and non-compliance can result in costly penalties and legal issues. Implementing pedestrian safety signs and symbols plays a vital role in meeting these regulatory requirements.

By incorporating standardized safety symbols and signage throughout the facility, warehouses demonstrate their commitment to complying with safety regulations. This not only helps avoid legal complications but also fosters a positive relationship with regulatory authorities, ensuring that the warehouse remains in good standing.

In conclusion, the implementation of pedestrian safety signs and symbols is a crucial aspect of maintaining a safe and efficient warehouse environment. By promoting safety awareness, preventing accidents and injuries, improving productivity, and meeting regulatory compliance, these simple yet effective measures contribute to the overall success of warehouse operations. Investing in advanced safety technologies, such as forklift pedestrian detection systems along with appropriate signage, further enhances worker safety and ensures a more secure working environment for all.

To learn more about advanced safety solutions for warehouses, including forklift pedestrian detection systems, visit HCO Innovations.

HCO Innovations is a prominent provider of warehouse optimization solutions based in Raleigh, NC. Their expertise lies in enhancing safety, productivity, efficiency, and cost-effectiveness within warehouse operations.

Why are pedestrian safety signs and symbols important in warehouses?

Pedestrian safety signs and symbols are crucial in warehouses to prevent accidents and ensure the well-being of employees and visitors. They provide clear visual cues and directions, helping to establish designated pedestrian walkways, hazardous zones, and traffic rules. By promoting awareness and guiding individuals on safe paths, these signs and symbols contribute to reducing the risk of collisions and injuries in high-traffic areas.

What types of pedestrian safety signs and symbols are commonly used in warehouses?

In warehouses, common examples of pedestrian safety signs and symbols include "Stop" signs, "No Entry" signs, "Crosswalk" symbols, and "Pedestrian Only" signs. Additional signage may include directional arrows, speed limit indicators, and pictographs illustrating specific hazards or actions like "Watch for Forklifts" or "Use Handrail."

How do pedestrian safety signs and symbols enhance warehouse efficiency?

By clearly indicating pedestrian routes and areas to avoid, safety signs and symbols help prevent accidents and congestion. By creating separate pathways for pedestrians and vehicles, these signs can improve traffic flow and reduce the likelihood of bottlenecks or delays. This enhanced efficiency contributes to smoother operations, increased productivity, and a safer working environment overall.

What are the benefits of using standardized pedestrian safety signs and symbols?

Standardized pedestrian safety signs and symbols are easily recognizable and universally understood. Using consistent and familiar signage reduces confusion among employees, contractors, and visitors, enhancing communication and promoting a safer work environment. Standardization also ensures compliance with regulatory requirements and industry best practices.

How can pedestrian safety signs and symbols be used to reinforce training and awareness?

Pedestrian safety signs and symbols serve as visual reminders of the training and protocols in place. By consistently displaying these signs throughout the warehouse, individuals are constantly reminded of the importance of safe pedestrian practices. This reinforcement helps to instill a culture of safety, making it more likely that employees and visitors will adhere to established guidelines and remain vigilant in their surroundings.

Are there legal requirements for pedestrian safety signs and symbols in warehouses?

In many countries, health and safety regulations outline specific requirements for signage in workplaces, including warehouses. While these requirements may vary, it is generally mandatory for warehouses to display adequate pedestrian safety signs and symbols to prevent accidents and comply with legal obligations. It is advisable to consult local legislation or consult with health and safety professionals to ensure compliance with specific requirements.

Can pedestrian safety signs and symbols be customized to fit specific warehouse needs?

Absolutely! While standardized signs and symbols are recommended for consistency and recognition, warehouses can customize signage to address unique hazards or requirements. Customization may include adding company logos, incorporating specific wording, or designing signs that reflect elements of the warehouse layout or workflows. However, it is essential to ensure that customized signs maintain clarity, visibility, and compliance with relevant regulations.

What can I do if I notice a lack of pedestrian safety signs and symbols in my warehouse?

If you notice a deficiency in pedestrian safety signs and symbols in your warehouse, it is crucial to address the issue promptly. Begin by documenting the specific areas or types of signs that are missing or inadequate. Then, notify the appropriate management or safety representative within your organization, sharing your concerns and recommendations for improvement. By bringing attention to the issue, you contribute to creating a safer workplace for everyone.

Promoting Warehouse Efficiency Through Lean Management Techniques

Efficiency is a key aspect of running a successful warehouse operation. In today's competitive business environment, companies are constantly seeking ways to optimize their operations, reduce costs, and improve overall productivity. One effective strategy for achieving these goals is through the implementation of lean management techniques. By adopting lean principles, warehouses can streamline their processes, eliminate waste, and maximize efficiency.

The Principles of Lean Management

At its core, lean management is a methodology that aims to eliminate waste and improve efficiency in all aspects of operations. Originally developed by Toyota in the 1950s, lean management has since been embraced by companies worldwide across various industries. The principles of lean management include:

- Value: Identify the value as perceived by the customer and focus on providing that value.

- Value Stream: Map out and analyze the entire value stream to identify areas of waste and inefficiency.

- Flow: Design processes that allow for a smooth flow of materials and information.

- Pull: Implement a pull system where products are produced based on customer demand.

- Perfection: Continuously strive for perfection by eliminating waste, improving processes, and empowering employees.

By applying these principles, warehouses can optimize their operations and achieve significant improvements in efficiency and productivity.

Eliminating Waste in Warehouse Operations

One of the main goals of lean management is to identify and eliminate waste. Waste can manifest in various forms within warehouse operations, including excessive inventory, unnecessary movement, defects, overproduction, waiting time, and excessive transportation. Identifying and reducing waste is crucial for streamlining processes and improving operational efficiency.

Here are several areas where warehouses can focus on eliminating waste:

- Inventory Management: Implementing efficient inventory management systems and practices can help reduce excess inventory, minimize carrying costs, and prevent stockouts. By using advanced inventory tracking software, warehouses can gain better visibility and control over their inventory levels, enabling them to optimize stocking levels and reduce waste.

- Layout Optimization: The layout of a warehouse plays a significant role in operational efficiency. By conducting a warehouse layout evaluation, warehouses can identify opportunities to rearrange storage areas, improve workflow, and minimize unnecessary material movements. Implementing lean principles, such as organizing items based on frequency of use and implementing visual management techniques, can help reduce waste and improve productivity.

- Material Handling: Efficient material handling can significantly impact warehouse efficiency. Adopting technologies such as automation, conveyor systems, and forklift fleet management can help streamline material flow and reduce wasted time and energy. Proper training for forklift operators and regular equipment maintenance are also essential for minimizing errors and downtime.

- Streamlined Processes: Analyzing and optimizing processes within the warehouse can eliminate bottlenecks, reduce waiting time, and improve overall flow. Implementing standard operating procedures, introducing error-proofing techniques, and utilizing visual aids can enhance productivity, reduce errors, and eliminate waste.

By addressing these areas, warehouses can experience significant improvements in efficiency, reduce costs, and enhance customer satisfaction.

The Benefits of Lean Management in Warehouse Operations

Implementing lean management techniques can offer several benefits to warehouse operations:

- Improved Efficiency: Lean techniques help eliminate waste and streamline processes, leading to increased efficiency and productivity. By optimizing material flow, reducing waiting time, and improving overall workflow, warehouses can achieve higher output with the same or fewer resources.

- Reduced Costs: Waste elimination directly translates into cost reduction. By minimizing excess inventory, avoiding stockouts, and optimizing material handling, warehouses can lower carrying costs, reduce product losses, and minimize labor and equipment expenses.

- Enhanced Customer Satisfaction: Lean management fosters a customer-centric approach, allowing warehouses to meet customer demands more effectively. By reducing lead times, improving order accuracy, and delivering products on time, warehouses can enhance customer satisfaction and build stronger relationships with clients.

- Empowered Employees: Lean management involves empowering employees to contribute ideas for improvement and take ownership of their work. Engaged and motivated employees are more likely to identify and solve problems, leading to a culture of continuous improvement and innovation.

- Competitive Advantage: Implementing lean principles can give warehouses a competitive edge in the market. By operating more efficiently, warehouses can offer lower prices, faster delivery times, and higher quality service, positioning themselves as the preferred choice for customers.

HCO Innovations: Your Partner in Warehouse Efficiency

HCO Innovations is a leading management consulting firm specializing in warehouse optimization and forklift fleet management. With a team of experienced consultants and advanced cost-tracking software, we help warehouses across industries achieve significant cost reductions and operational efficiency.

Our comprehensive services include warehouse layout evaluation, safety assessments, turnkey maintenance solutions, and the implementation of lean management techniques. We take a collaborative "boots on the ground" approach, working closely with our clients to identify areas of improvement and develop tailored solutions to drive efficiency and reduce material handling costs.

Partnering with HCO Innovations ensures that your warehouse operations are optimized for maximum efficiency and cost-effectiveness. We understand the unique challenges faced by warehouses and offer practical solutions that deliver a remarkable return on investment.

Ready to take your warehouse efficiency to the next level? Contact us today to schedule a consultation with our experts!