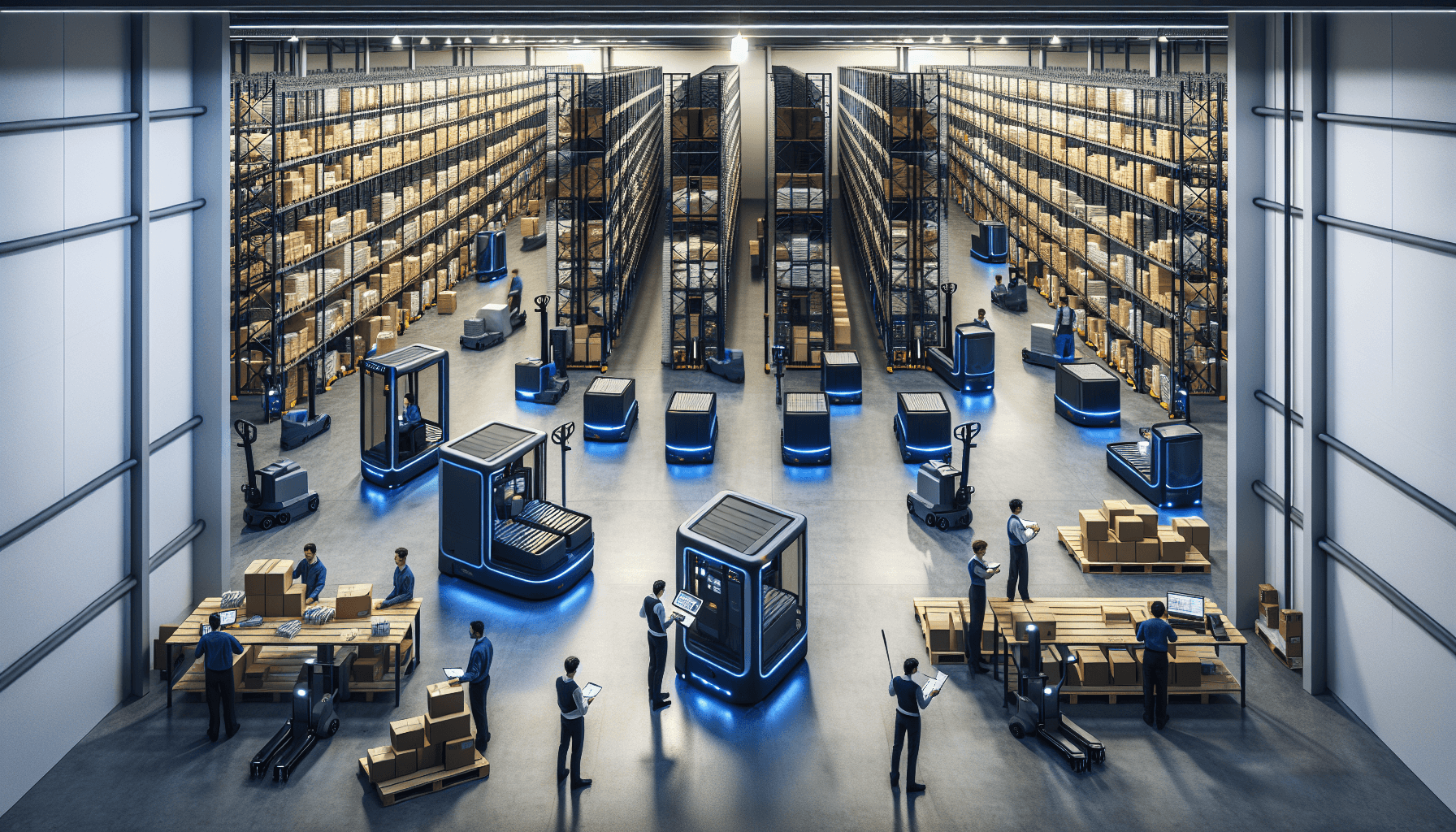

In today’s fast-paced and highly competitive business landscape, warehouse operations play a crucial role in the success of any organization. As companies strive to improve productivity, efficiency, and cost-effectiveness within their warehouses, finding innovative solutions becomes imperative. One such solution that has gained significant traction in recent years is the implementation of Automated Guided Vehicles (AGVs).

The Rise of AGVs

AGVs are autonomous vehicles that are designed to perform a variety of tasks within a warehouse environment. These vehicles, equipped with advanced navigation systems and sensors, can move goods around the warehouse without the need for manual intervention. They have the ability to transport goods, pick and place items, and even navigate through narrow aisles with ease.

With the advancement in technology, AGVs have become increasingly sophisticated, capable of integrating with existing warehouse management systems and operating seamlessly with other machinery and equipment. They are a valuable addition to any warehouse looking to optimize their operations and maximize efficiency.

The Benefits of Implementing AGVs

Implementing AGVs offers a wide range of benefits for warehouse operations. Let’s explore some of the key advantages:

- Increased Productivity: AGVs are designed to work tirelessly, providing a significant boost to productivity. These vehicles can operate 24/7, eliminating the need for breaks or shift changes. With their ability to navigate efficiently and perform tasks quickly, AGVs can handle a higher volume of work compared to manual labor.

- Enhanced Safety: Safety is a top priority in any warehouse environment. By implementing AGVs, companies can significantly reduce the risk of accidents and injuries. AGVs are equipped with advanced safety features, such as collision avoidance sensors and emergency stop capabilities, ensuring a safe working environment for both employees and the machinery.

- Improved Efficiency: AGVs are programmed to follow the most efficient routes within the warehouse, avoiding congestion and minimizing travel time. This not only speeds up operations but also reduces energy consumption. AGVs can also optimize storage space by utilizing the available area more effectively and reducing the need for excessive aisle space.

- Reduced Labor Costs: Labor costs can be a significant portion of a warehouse’s expenses. By replacing manual labor with AGVs, companies can save costs associated with hiring, training, and managing employees. AGVs offer a more cost-effective solution in the long run, especially for repetitive and physically demanding tasks.

- Flexibility and Scalability: AGVs can be easily programmed and reprogrammed to adapt to changing warehouse needs. As businesses grow and evolve, AGVs can be scaled up or reconfigured to accommodate new layouts, processes, and product lines. This flexibility allows companies to stay agile and responsive to market demands.

Given the numerous benefits, it’s no surprise that more and more warehouse operators are turning to AGVs to optimize their operations. Implementing AGVs can revolutionize the way a warehouse functions, leading to increased productivity, enhanced safety, improved efficiency, and reduced costs.

At HCO Innovations, we specialize in providing comprehensive warehouse optimization solutions, including the deployment of AGVs. Our team of experts can help evaluate your warehouse needs and design a customized AGV system tailored to your specific requirements. By leveraging our expertise and cutting-edge technology, you can unlock the full potential of your warehouse operations.

If you’re ready to take your warehouse productivity to the next level, get in touch with us today and discover how AGVs can revolutionize your operations.