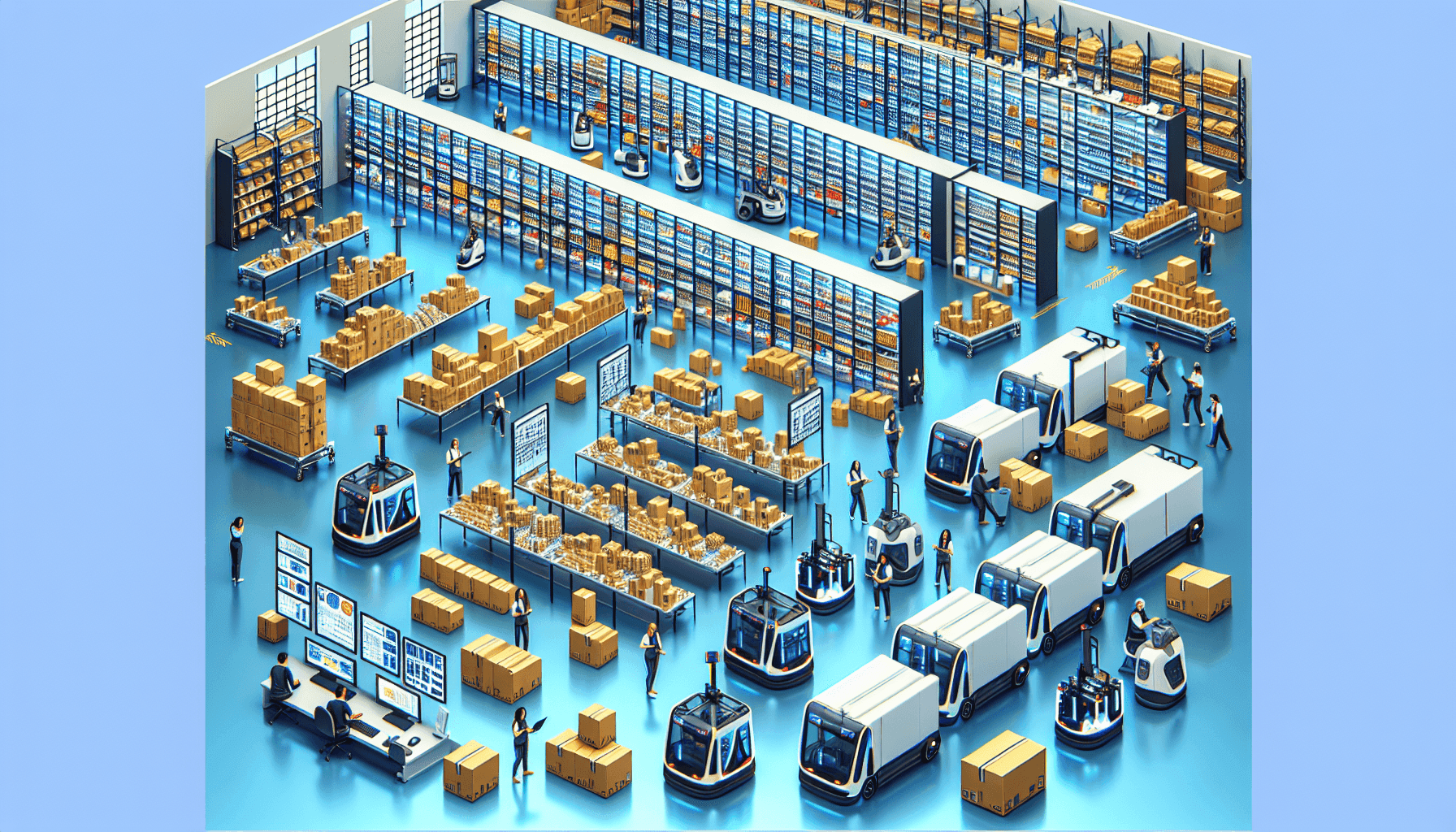

Automated Guided Vehicles (AGVs) have revolutionized the way e-commerce fulfillment centers operate. These robotic systems offer a wide range of benefits, from improving warehouse efficiency to enhancing safety and reducing operational costs. In this article, we will discuss the role of AGVs in e-commerce fulfillment centers and how they can optimize warehouse operations.

Enhancing Efficiency

AGVs play a crucial role in streamlining the fulfillment process in e-commerce warehouses. These intelligent robots are programmed to perform tasks such as picking, sorting, and transporting goods within the warehouse. Unlike human workers, AGVs can work continuously without breaks or fatigue, ensuring a consistent level of productivity throughout the day.

AGVs are designed to navigate through the warehouse autonomously using advanced technologies such as LiDAR sensors, cameras, and mapping software. They can identify obstacles, avoid collisions, and find the most efficient route to complete their tasks. By eliminating human errors and optimizing travel paths, AGVs can significantly reduce the time required to fulfill customer orders, resulting in faster order processing and improved customer satisfaction.

Furthermore, AGVs can work in collaboration with warehouse management systems (WMS), allowing for seamless integration of data and inventory management. These intelligent systems can communicate with the WMS to receive real-time order information, update inventory levels, and monitor the status of each fulfillment task. With accurate and up-to-date information, warehouse managers can make informed decisions to optimize the use of AGVs and other resources, further improving efficiency and throughput in the warehouse.

Ensuring Safety

Safety is a top priority in any warehouse environment, and AGVs offer several features to enhance workplace safety. These robotic systems are equipped with advanced sensors and algorithms that allow them to detect and avoid obstacles, including humans. They can adjust their speed, change routes, or come to a complete stop to prevent accidents in real-time.

AGVs also help reduce the risk of injury by minimizing the need for manual material handling. Tasks that involve heavy lifting, repetitive motions, or working in hazardous conditions can be assigned to AGVs, freeing up human workers to focus on more skilled and less physically demanding tasks. By reducing the physical strain on workers, AGVs contribute to a safer work environment and reduce the likelihood of workplace injuries.

Cost-Effectiveness

Implementing AGVs in e-commerce fulfillment centers can result in significant cost savings. While the initial investment in AGV technology may seem substantial, the long-term benefits outweigh the costs. AGVs offer a higher level of productivity compared to manual labor, reducing the need for additional human resources. Additionally, these robots can operate 24/7 without overtime pay, improving operational efficiency and reducing labor costs.

AGVs also help optimize warehouse space utilization. With their ability to navigate in narrow aisles and stack goods efficiently, AGVs can maximize the use of available space. This eliminates the need for additional storage facilities, reducing real estate costs for warehouses. Moreover, AGVs can minimize product damage by handling goods carefully, further reducing costs associated with damaged or lost inventory.

By integrating AGVs with other automation technologies such as conveyor systems, automated picking systems, and warehouse control systems, e-commerce fulfillment centers can create a seamlessly automated workflow. This increases overall operational efficiency, reduces order fulfillment lead times, and improves inventory accuracy. The result is a highly cost-effective warehouse operation that can quickly adapt to changing customer demands.

Conclusion

AGVs play a vital role in optimizing e-commerce fulfillment centers. They enhance efficiency by automating repetitive tasks and optimizing travel routes, resulting in faster order processing and improved customer satisfaction. AGVs contribute to a safer work environment by reducing the risk of workplace injuries and improving workplace safety. Additionally, these robotic systems offer cost-effectiveness through improved productivity, reduced labor costs, and better space utilization. Investing in AGV technology can transform e-commerce fulfillment centers into highly efficient and competitive operations.

If you are interested in implementing AGVs in your warehouse and want to explore the benefits they can offer, visit HCO Innovations for more information on AGV deployment services.