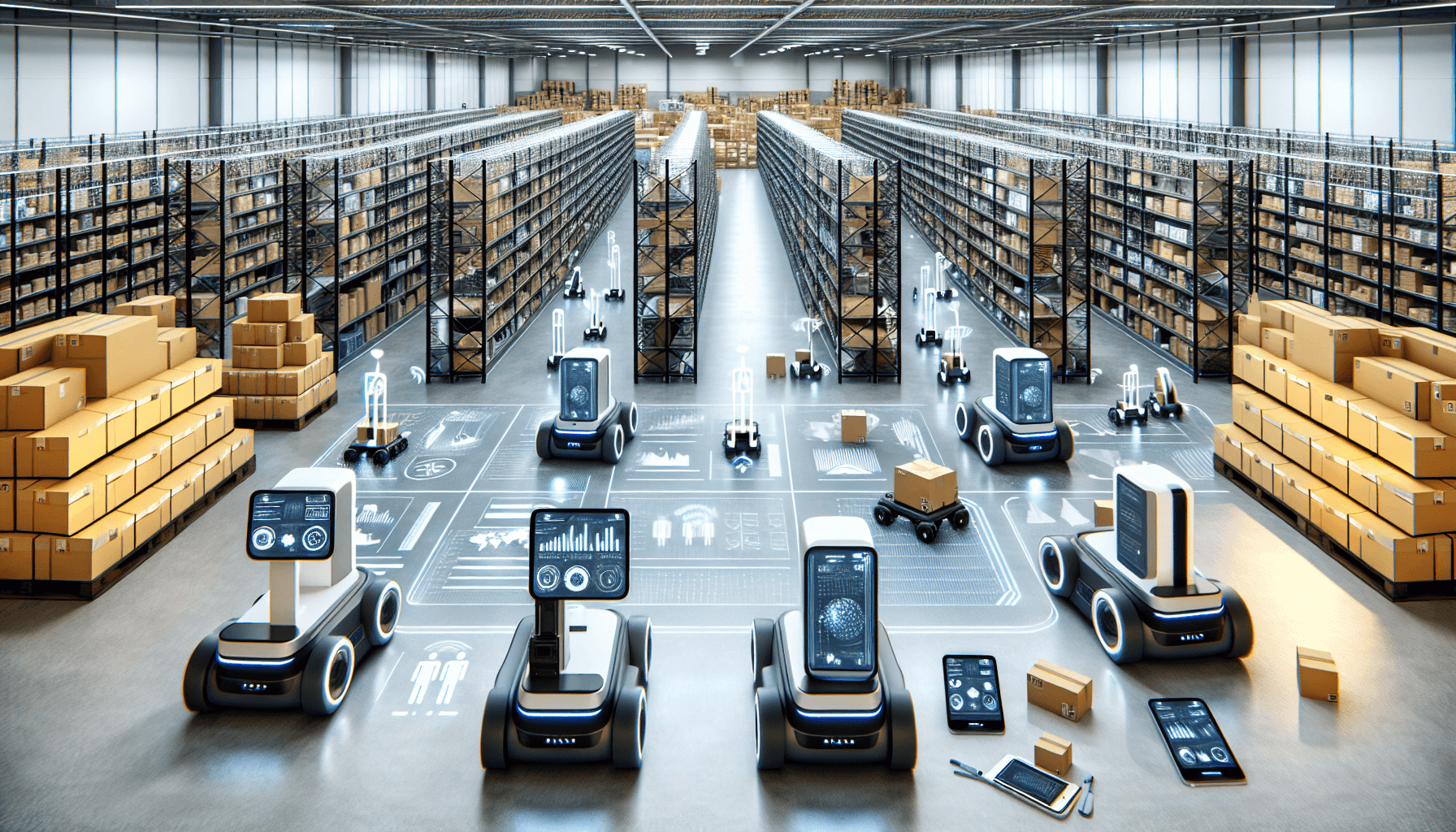

Warehouse operations are constantly evolving and looking for ways to improve their safety, productivity, efficiency, and cost-effectiveness. One innovative solution that has revolutionized the way warehouses collect and analyze data is the use of Automated Guided Vehicles (AGVs). These advanced robotic systems have proven to be a game-changer for warehouse optimization, offering a range of benefits that can significantly enhance operations.

Data Collection and Analysis Challenges in Warehouses

Before diving into how AGVs can address these challenges, it’s important to understand the data collection and analysis hurdles that warehouses often face. Traditionally, warehouse managers have relied on manual data collection methods, such as paper-based systems or manual data entry, which can be time-consuming and prone to errors. This not only slows down operations but also hampers the accuracy of the collected data.

Furthermore, the sheer amount of data generated within a warehouse can be overwhelming. Real-time visibility into key performance indicators (KPIs) like order processing time, inventory levels, and cycle counts becomes crucial for making proactive decisions. Without proper data collection and analysis tools, warehouses may find it challenging to gain actionable insights.

The Role of AGVs in Data Collection

AGVs have emerged as a powerful tool for collecting warehouse data efficiently and accurately. Equipped with advanced sensors, barcode readers, and integrated software systems, AGVs can seamlessly navigate through the warehouse and collect data at different stages of the supply chain process.

One key advantage of AGVs is their ability to automate inventory management. By scanning barcodes or utilizing RFID technology, AGVs can quickly and accurately track item location and quantities. This eliminates the need for manual inventory counts, reducing the chances of errors and improving inventory accuracy.

AGVs can also collect valuable data related to order processing. These robotic systems can move goods from one location to another within the warehouse, logging the time it takes to complete each task. This data can be utilized to analyze and optimize the order fulfillment process, identifying bottlenecks and areas for improvement.

Moreover, AGVs can gather data on the movement and utilization of warehouse equipment. They can monitor the usage of forklifts, pallet jacks, and other machinery, providing insights into their efficiency and maintenance needs. This data can help warehouse managers proactively schedule maintenance and minimize equipment downtime.

Benefits of AGV-Enabled Data Collection and Analysis

The integration of AGVs in warehouse data collection and analysis brings numerous benefits to warehouse operations:

- Improved Accuracy: AGVs eliminate human errors associated with manual data collection, resulting in more reliable and accurate data.

- Real-Time Tracking: AGVs provide real-time visibility into inventory levels, order status, and other critical metrics, enabling proactive decision-making.

- Increased Efficiency: With AGVs handling repetitive tasks, warehouse staff can focus on more value-added activities, boosting overall operational efficiency.

- Enhanced Productivity: AGVs can operate 24/7, improving productivity by enabling round-the-clock operations.

- Optimized Space Utilization: AGVs navigate through the warehouse using the most efficient paths, maximizing storage space utilization.

However, simply collecting data is not enough. It is equally important to analyze and interpret the data to derive actionable insights. AGVs, in conjunction with advanced analytics tools and software, enable warehouses to analyze data in real-time, identify patterns, and make data-driven decisions. This enables continuous improvement and optimization of warehouse operations.

By leveraging AGVs for data collection and analysis, warehouses can unlock the full potential of their data. They can identify areas for process improvement, streamline operations, and enhance overall performance.

To effectively deploy AGVs and reap the benefits of warehouse data collection and analysis, it is essential to partner with a trusted provider of warehouse optimization solutions like HCO Innovations. Their expertise in AGV deployment and warehouse optimization can help warehouses transform their operations and achieve their goals.

In conclusion, AGVs play a vital role in enhancing warehouse data collection and analysis. They offer an automated and accurate solution for collecting data, helping warehouses gain real-time visibility, improve accuracy, and optimize their operations. By embracing AGVs and leveraging advanced analytics tools, warehouses can stay ahead of the competition and maximize their efficiency and profitability.