In today’s fast-paced business environment, efficient warehouse operations are crucial for the success of any company. One of the key areas that can greatly impact warehouse efficiency is the picking process. Efficient picking ensures that orders are fulfilled accurately and in a timely manner, leading to higher customer satisfaction and increased productivity. One technology that has revolutionized the picking process is Automated Guided Vehicles (AGVs).

What are AGVs?

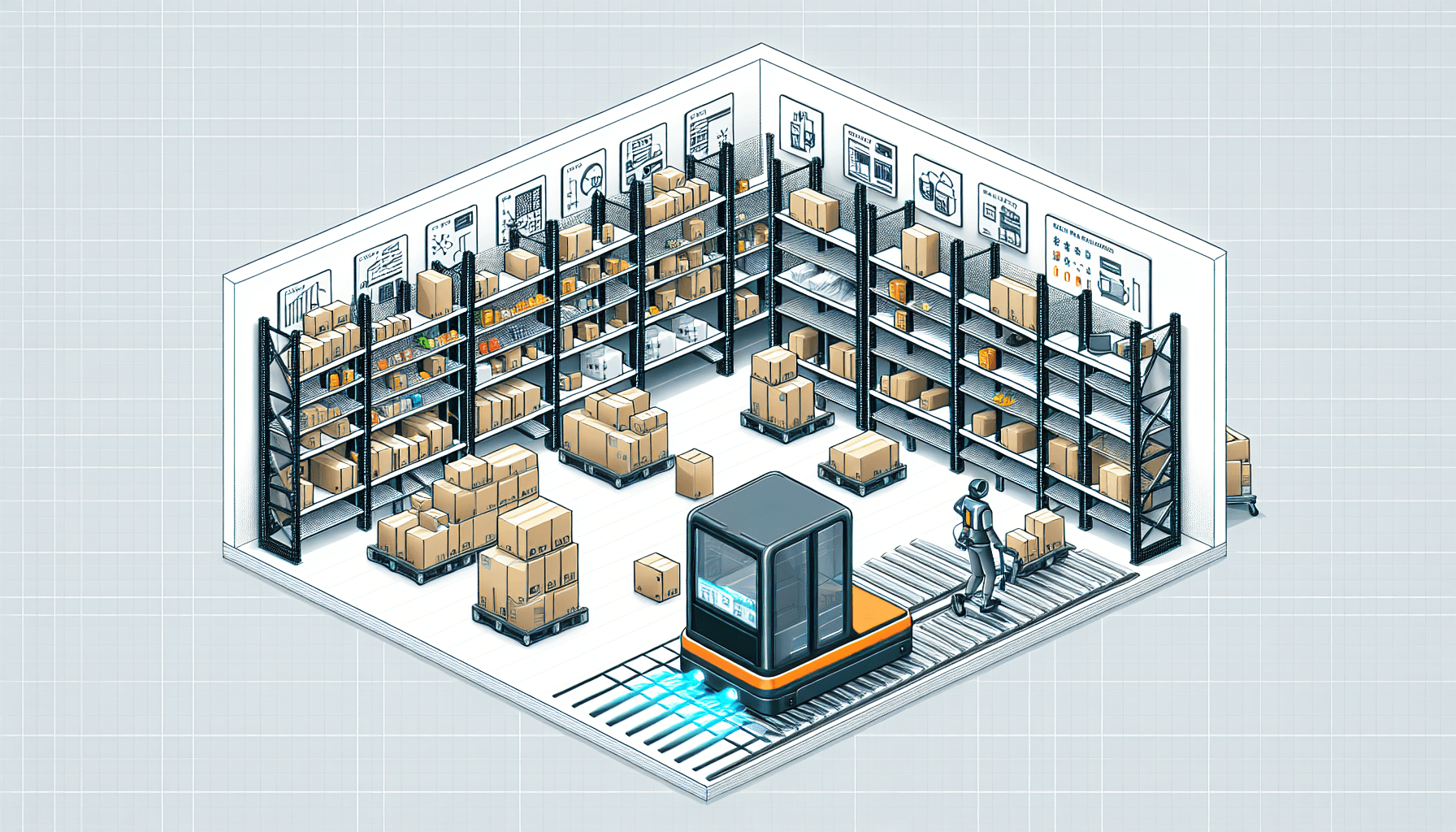

AGVs are robotic vehicles designed to automate material handling tasks within a warehouse. These vehicles are equipped with advanced sensors and navigation systems that allow them to move safely and independently throughout the warehouse, picking up and delivering materials or products to designated locations. AGVs are customizable and can be programmed to handle a wide range of tasks, including picking, transporting, and sorting items.

AGVs come in various sizes and configurations, from small and compact models to large and heavy-duty vehicles capable of handling bulky or heavy loads. These robots can operate on different surfaces, such as concrete floors or even racks and shelves, depending on the specific requirements of the warehouse.

How do AGVs Improve Warehouse Picking Efficiency?

Implementing AGVs in warehouse operations can bring about several benefits that significantly improve picking efficiency. Let’s take a closer look at how AGVs achieve this:

- Increased Speed and Accuracy: AGVs can navigate through the warehouse quickly and efficiently, reducing the time required to locate and pick items. Their advanced sensors and navigation systems allow them to follow the most optimal routes, avoiding obstacles and congestion. This results in faster picking times and improved order accuracy.

- 24/7 Operation: Unlike human workers who require breaks and rest periods, AGVs can operate continuously, allowing for round-the-clock picking operations. This ensures that orders can be processed and fulfilled even during non-working hours, reducing the overall turnaround time and improving customer satisfaction.

- Reduced Labor Costs: By automating the picking process with AGVs, companies can significantly reduce their dependence on manual labor. This leads to cost savings in terms of labor wages, training, and benefits. AGVs can efficiently handle repetitive and labor-intensive tasks, freeing up human workers to focus on more complex and value-added activities within the warehouse.

- Improved Safety: AGVs are designed with advanced safety features, such as collision detection sensors and emergency stop mechanisms, to ensure a safe working environment. By minimizing the risk of accidents and injuries, AGVs contribute to a safer and more secure warehouse operation.

- Real-time Tracking and Monitoring: AGVs are equipped with sophisticated tracking and monitoring systems that provide real-time visibility into the picking process. Warehouse managers can track the status of orders, monitor the performance of AGVs, and identify any bottlenecks or inefficiencies in the picking process. This data-driven approach enables timely decision-making and process optimization.

AGVs from HCO Innovations

When it comes to implementing AGVs in your warehouse, you need a reliable and experienced partner. HCO Innovations specializes in warehouse optimization solutions and offers top-of-the-line AGV systems. Their expertise and industry knowledge enable them to provide customized AGV solutions tailored to the specific requirements of your warehouse.

With HCO Innovations’ AGV systems, you can expect improved picking efficiency, enhanced safety, and increased productivity within your warehouse operations. Their solutions are designed to optimize your warehouse processes, from picking to sorting and transportation, ensuring a streamlined and cost-effective operation.

Conclusion

Automated Guided Vehicles (AGVs) have become a gamechanger in warehouse operations, particularly in the picking process. By harnessing the power of robotics and automation, AGVs significantly improve picking efficiency, leading to faster order fulfillment, reduced labor costs, and enhanced safety. If you’re looking to optimize your warehouse and improve picking efficiency, consider integrating AGVs from HCO Innovations. Click here to learn more about their AGV deployment services.