In today’s fast-paced and competitive business environment, scalability is a crucial factor for warehouse operations. As businesses grow and evolve, the ability to adapt and expand their warehouse capabilities becomes paramount. This is where Automated Guided Vehicles (AGVs) play a vital role in enhancing warehouse scalability.

The Rise of AGVs

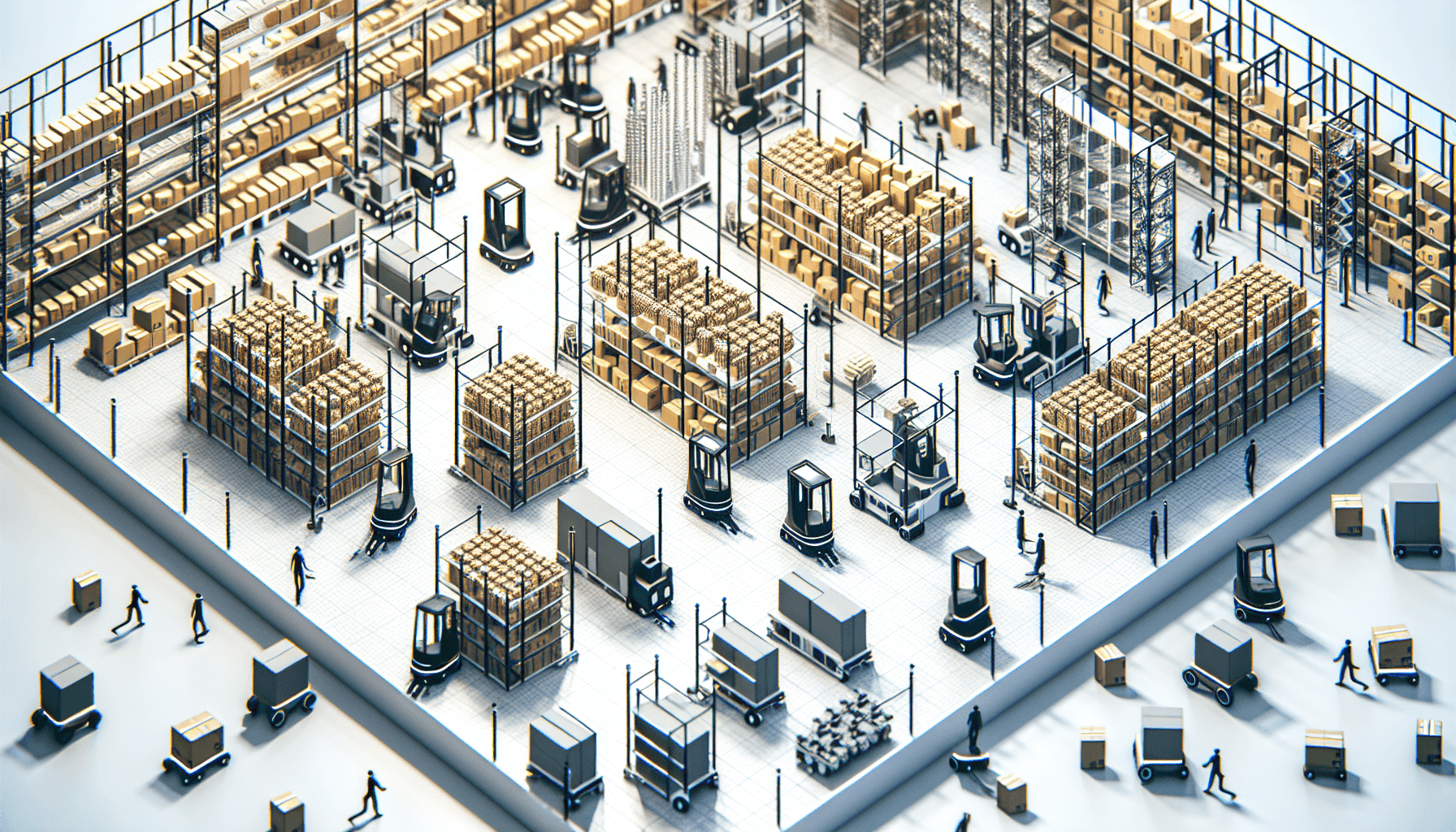

AGVs have revolutionized the way warehouses operate by providing an automated solution for material handling tasks. These self-guided vehicles navigate through the warehouse floor, transporting goods from one location to another, without the need for human intervention. This technology has gained significant popularity in recent years due to the numerous benefits it offers.

One of the key advantages of AGVs is their flexibility. These vehicles can be easily programmed and reprogrammed to perform various tasks, making them ideal for dynamic warehouse environments. As business needs change, AGVs can quickly adapt to new workflows and processes, allowing warehouses to scale their operations seamlessly.

Another important aspect of AGVs is their ability to optimize space utilization. These vehicles are designed to navigate efficiently through narrow aisles, maximizing the available storage space. By leveraging the potential of vertical space within the warehouse, businesses can significantly increase their storage capacity without the need for costly expansions or relocations.

The Role of AGVs in Enhancing Warehouse Scalability

AGVs play a crucial role in enhancing warehouse scalability in multiple ways:

- Improved Efficiency: AGVs eliminate the need for manual material handling, reducing the time and effort required to move goods within the warehouse. With their advanced navigation capabilities, AGVs can optimize travel routes, minimize idle time, and complete tasks faster. This increased efficiency allows businesses to handle higher volumes of work without compromising on accuracy or speed.

- Flexibility and Adaptability: As mentioned earlier, AGVs are highly flexible and adaptable to changing warehouse needs. These vehicles can be easily integrated into existing warehouse infrastructure and can be programmed to perform multiple tasks, such as loading and unloading, picking and packing, and even assembly operations. By simply reprogramming AGVs, warehouses can quickly accommodate new products, processes, or layouts, ensuring scalability with minimal disruption.

- Increase in Productivity: AGVs can work tirelessly, 24/7, without the limitations of human fatigue. This continuous operation translates into increased productivity for the warehouse, as tasks can be completed round the clock. Moreover, AGVs can be synchronized to work in tandem with other warehouse automation systems, such as conveyor belts and robotic arms, further enhancing productivity and throughput.

- Enhanced Safety: Safety is always a top priority in warehouse operations. AGVs are equipped with advanced safety features, including laser scanners, sensors, and collision avoidance systems, to ensure safe navigation and prevent accidents. By reducing the risk of human error and minimizing the chances of workplace injuries, AGVs contribute to a safer warehouse environment.

- Cost-Effectiveness: Implementing AGVs in warehouse operations can lead to significant cost savings in the long run. Firstly, by increasing efficiency and productivity, businesses can handle higher workloads without the need for additional labor. This reduction in labor costs can be substantial, particularly in labor-intensive industries. Furthermore, AGVs eliminate the need for expensive infrastructure modifications or expansions, as they can make the most of existing warehouse layouts.

Overall, AGVs are a game-changer when it comes to enhancing warehouse scalability. By leveraging their flexibility, efficiency, and safety features, businesses can optimize their operations, maximize space utilization, improve productivity, and reduce costs. Investing in AGV technology allows warehouses to keep up with evolving customer demands and grow their operations without constraints.

If you’re interested in harnessing the power of AGVs for your warehouse, HCO Innovations offers comprehensive warehouse optimization solutions. Their expertise in AGV deployment and warehouse management systems can help you unlock the full potential of your warehouse and enable seamless scalability.