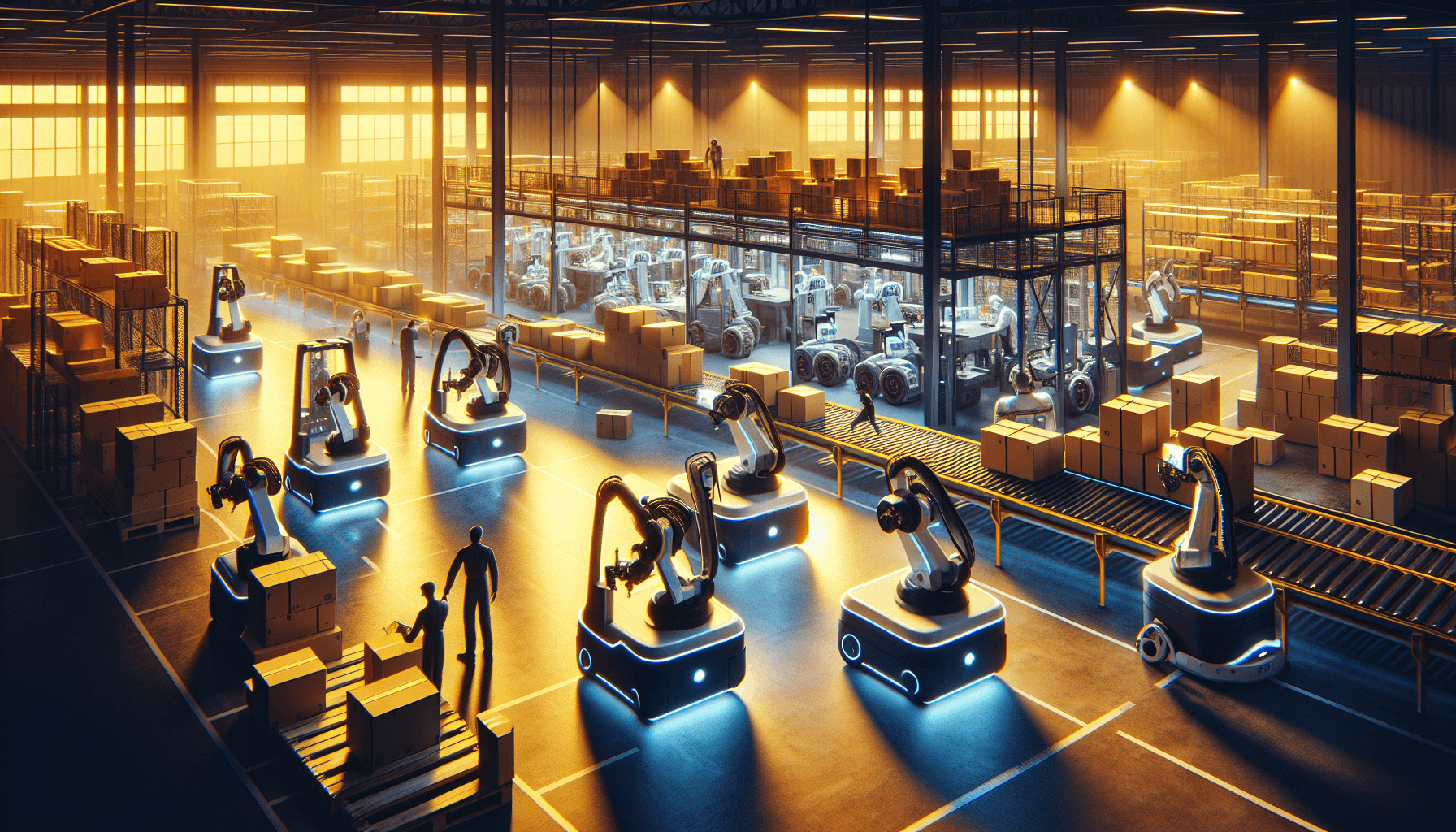

Warehouse operations are an integral part of any supply chain. To ensure smooth operations, it is essential to optimize efficiency, productivity, and safety within the warehouse. One solution that has gained popularity in recent years is the use of Automated Guided Vehicles (AGVs) for packaging and assembly operations.

What are AGVs?

AGVs are robotic vehicles that are designed to navigate and perform tasks in a warehouse or manufacturing setting. These vehicles are equipped with sensors and advanced software that enable them to move autonomously without the need for human intervention. They can transport materials, components, and finished products within the warehouse, minimizing the need for manual labor.

AGVs come in various types and configurations, depending on the specific requirements of the warehouse. They can be equipped with forks, conveyor belts, or robotic arms to handle different types of loads. The vehicles can be programmed to follow pre-defined paths, avoid obstacles, and interact safely with humans and other equipment in the warehouse.

The Benefits of AGVs for Packaging and Assembly Operations

1. Increased Efficiency: AGVs can significantly improve efficiency within packaging and assembly operations. These vehicles can work 24/7 without breaks, reducing downtime and increasing overall productivity. They can also perform tasks at a faster pace than manual labor, leading to quicker turnaround times and improved customer satisfaction.

2. Enhanced Safety: Safety is a top priority in warehouse operations, and AGVs are designed with safety features to prevent accidents. These vehicles are equipped with sensors that detect obstacles and humans in their proximity, enabling them to slow down or stop to avoid collisions. AGVs also eliminate the risks associated with manual handling of heavy loads, reducing the chances of injuries for warehouse employees.

3. Optimal Space Utilization: AGVs can navigate through narrow aisles and tight spaces, allowing for efficient use of warehouse floor space. These vehicles can be programmed to follow specific paths, optimizing the layout of the warehouse and minimizing wastage of space. AGVs can also stack pallets and shelves at different heights, maximizing vertical storage space.

4. Cost-Effectiveness: While the initial investment may be higher compared to manual labor, AGVs can save costs in the long run. With AGVs, there is no need to hire and train additional staff, reducing labor costs. These vehicles also require less maintenance compared to traditional forklifts or other material handling equipment, resulting in lower maintenance expenses.

5. Flexibility and Scalability: AGVs offer flexibility and scalability to adapt to changing warehouse requirements. These vehicles can be reprogrammed or reconfigured to accommodate varying load sizes, changing production volumes, or reorganized workflows. This flexibility allows businesses to scale their operations without significant disruptions or the need for additional infrastructure.

6. Data Collection and Analysis: AGVs are equipped with sensors and software that enable them to collect and transmit data in real-time. This data can provide valuable insights into warehouse operations, such as the number of trips made, travel times, and product volumes moved. Analyzing this data can help identify areas for improvement, optimize workflows, and make informed decisions to further enhance warehouse efficiency.

HCO Innovations specializes in AGV deployment for warehouse optimization. Their team of experts can assess your warehouse needs, design customized AGV solutions, and provide seamless integration with your existing systems. They offer a range of AGV types, including pallet trucks, forklifts, and robotic arms, to cater to various packaging and assembly operations.

In conclusion, AGVs offer numerous benefits for packaging and assembly operations in warehouses. They enhance efficiency, improve safety, optimize space utilization, and provide cost-effectiveness. The flexibility and scalability of AGVs, coupled with data collection capabilities, enable businesses to streamline their operations and achieve higher levels of productivity. Consider implementing AGVs in your warehouse to stay ahead in today’s competitive marketplace.

What are AGVs?

AGVs (Automated Guided Vehicles) are robotic vehicles designed to perform tasks without the need for human intervention. In the context of packaging and assembly operations, AGVs are specifically designed to transport and move materials, products, or components within a facility or production line.

How do AGVs benefit packaging and assembly operations?

AGVs offer several benefits for packaging and assembly operations. They can automate material handling tasks, reduce manual labor, improve safety by minimizing human involvement in repetitive or hazardous tasks, increase efficiency and productivity by optimizing workflows, and provide real-time data and analytics for better decision-making and process improvement.

What types of tasks can AGVs perform in packaging and assembly operations?

AGVs can perform a wide range of tasks in packaging and assembly operations. They can transport raw materials, components, or finished goods within the facility, deliver materials to production lines or workstations, load and unload products from machines or conveyors, perform inventory management, and even assist in quality control inspections.

Are AGVs flexible enough to adapt to different packaging and assembly layouts?

Yes, AGVs are highly flexible and can adapt to different packaging and assembly layouts. They can be programmed or configured to navigate complex paths, avoid obstacles, and work in confined spaces. Additionally, they can be equipped with various attachments or tools to handle different types of materials or products.

What are the cost savings associated with implementing AGVs in packaging and assembly operations?

Implementing AGVs in packaging and assembly operations can lead to significant cost savings. By automating material handling tasks, companies can reduce labor costs, minimize product damage and waste, improve production efficiency, and optimize resource utilization. Additionally, AGVs can contribute to lower maintenance costs compared to traditional conveyor systems or manual forklifts.

Can AGVs integrate with existing packaging and assembly equipment?

Yes, AGVs can integrate with existing packaging and assembly equipment. They can be seamlessly integrated with production lines, conveyor systems, or other machinery to ensure smooth material flow and operation. Integration can be achieved through various methods, including sensor-based navigation, communication interfaces, and customization based on specific equipment requirements.

What safety features do AGVs have to prevent accidents or collisions?

AGVs are equipped with several safety features to prevent accidents or collisions. They can have sensors to detect obstacles or humans in their path and automatically adjust their speed or stop when necessary. Some AGVs are also equipped with advanced safety systems like laser scanners, emergency stop buttons, and audible alarms to ensure a safe working environment.

Can AGVs contribute to sustainability efforts in packaging and assembly operations?

Yes, AGVs can contribute to sustainability efforts in packaging and assembly operations. By optimizing material handling processes, reducing waste, and improving energy efficiency, AGVs can help companies minimize their environmental footprint. AGVs often use electric power, leading to lower greenhouse gas emissions compared to traditional fossil fuel-powered equipment.

What are the potential challenges or considerations when implementing AGVs in packaging and assembly operations?

Implementing AGVs in packaging and assembly operations requires careful planning and consideration. Some potential challenges include upfront investment costs, integration with existing systems, employee training and acceptance, potential disruptions during implementation, and the need for ongoing maintenance and support. It's important to conduct a thorough analysis to assess feasibility and ensure a seamless transition.

The Future of Robotics in Manufacturing

In today's rapidly evolving world, technology plays a pivotal role in driving innovation across various industries. One sector that has witnessed significant advancements in recent years is manufacturing. With the advent of robotics, factories and warehouses have experienced a dramatic transformation, leading to improved productivity, efficiency, and profitability. In this article, we will explore the exciting future of robotics in manufacturing and the ways it is revolutionizing the industry.

The Rise of Robotics in Manufacturing

Robots have become an integral part of modern manufacturing processes, with their ability to perform repetitive tasks accurately and efficiently. As businesses strive to streamline operations and increase output, robotics has emerged as a game-changing technology. Manufacturers are increasingly turning to robotics to automate labor-intensive processes, reduce costs, and enhance overall productivity.

One of the key driving factors behind the rise of robotics in manufacturing is the advancements in artificial intelligence (AI). With AI capabilities, robots can learn and adapt to new situations, making them more versatile and adaptable in dynamic production environments. They can analyze data in real-time, make decisions, and even collaborate with human workers, leading to greater efficiency and collaboration.

Another significant development is the miniaturization of robotic systems. Smaller and more agile robots can perform tasks in confined spaces, allowing them to be seamlessly integrated into existing production lines without major disruptions. This flexibility offers manufacturers the opportunity to optimize workflow and achieve higher levels of precision and accuracy.

The Benefits of Robotics in Manufacturing

The integration of robotics into manufacturing processes brings numerous benefits to businesses. Let's explore some of the key advantages:

- Increased Efficiency: Robots can perform tasks faster and with higher consistency compared to human workers. This leads to improved production output and reduced cycle times, ultimately increasing overall efficiency.

- Enhanced Safety: By assigning robots to perform dangerous or hazardous tasks, manufacturers can significantly minimize the risk of accidents and injuries to human workers. This promotes a safer working environment.

- Improved Quality: Robots are programmed to maintain precise control over manufacturing processes, resulting in higher product quality and reduced defects. This leads to better customer satisfaction and reduces the costs associated with rework or returns.

- Cost Reduction: While the initial investment in robotics may be significant, it can lead to long-term cost savings. Robots can work continuously without breaks or overtime pay, reducing labor costs over time. Additionally, they require less floor space and can optimize energy consumption, further contributing to cost reduction.

- Increased Flexibility: With the ability to program robots for various tasks, manufacturers can quickly adapt to changing production needs and market demands. This flexibility allows for easy reconfiguration, minimizing downtime and maximizing operational efficiency.

The Future of Robotics in Manufacturing

The future of robotics in manufacturing holds even more exciting possibilities. As technology continues to advance, we can expect the following trends to shape the industry:

- Collaborative Robots (Cobots): Cobots are designed to work alongside human workers, collaborating on tasks in a shared workspace. These robots possess advanced sensors and AI algorithms, enabling them to detect and respond to human presence, ensuring safe and efficient cooperation.

- IoT Integration: The integration of robotics with the Internet of Things (IoT) will enable seamless connectivity and data exchange between systems. This integration will allow manufacturers to monitor, analyze, and optimize production processes in real-time, leading to increased efficiency and reduced downtime.

- Autonomous Mobile Robots: Mobile robots equipped with autonomous navigation capabilities will enable the automation of material handling tasks within warehouses and factories. These robots can navigate through complex environments, transport goods, and collaborate with human workers, increasing operational efficiency and reducing the reliance on traditional forklifts and other heavy machinery.

- Advanced Machine Learning: As AI continues to evolve, robots will become more intelligent and capable of learning from experience. This will enhance their problem-solving abilities, enabling them to handle more complex tasks and adapt to dynamic production requirements.

- Human-Robot Collaboration: The future of manufacturing will involve a higher degree of collaboration between humans and robots. With robots taking over repetitive and physically demanding tasks, human workers can focus on more creative, strategic, and high-value activities, leading to a more fulfilling and productive work environment.

As HCO Innovations, a leading management consulting firm, we embrace the future of robotics in manufacturing and understand its immense potential. With our expertise in warehouse optimization and forklift fleet management, we assist businesses in harnessing the power of robotics to optimize their operations, reduce material handling costs, and achieve significant cost reductions. Visit our website to learn more about our comprehensive services and how we can help your business thrive in the era of robotics in manufacturing.