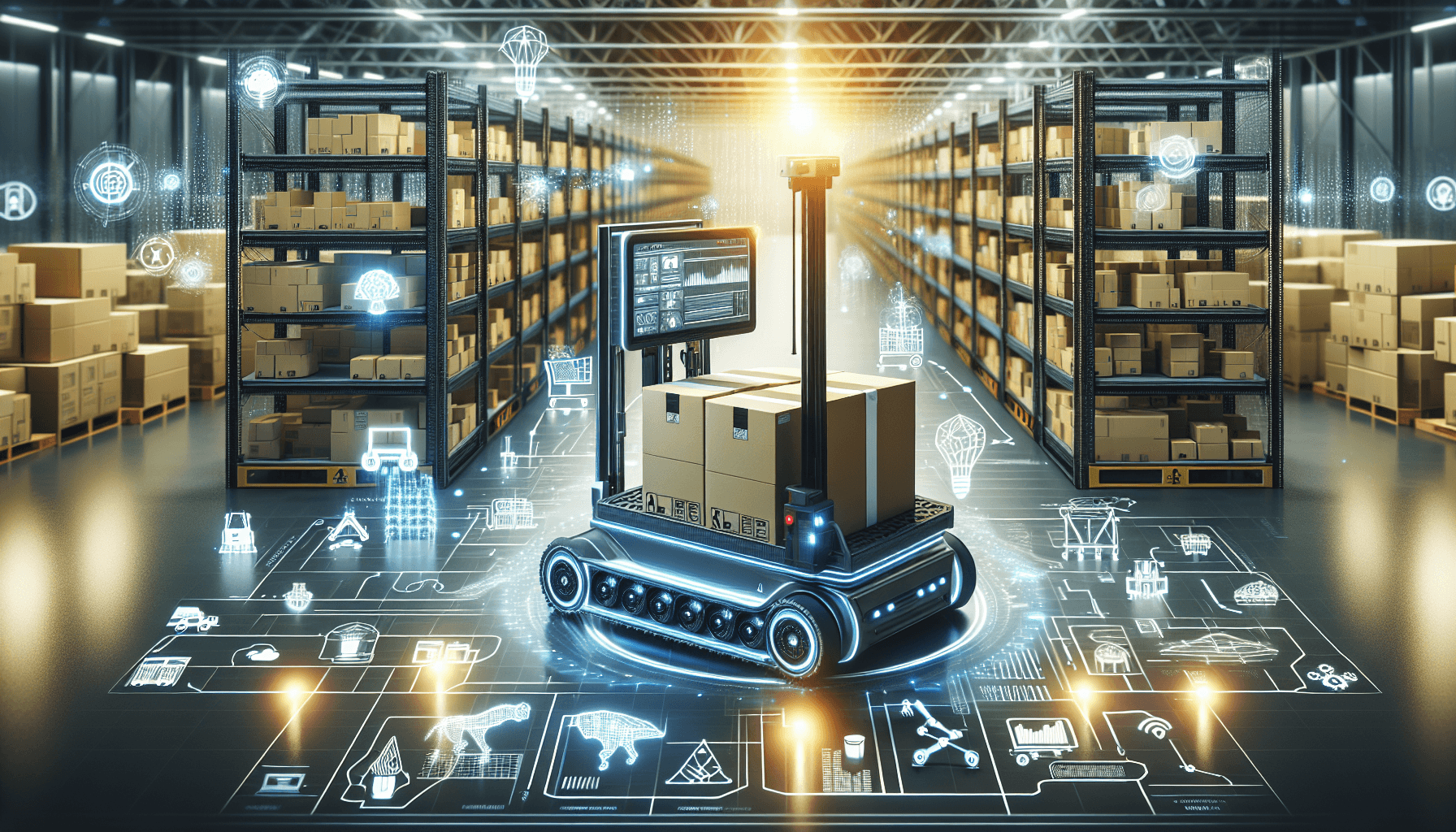

In today’s rapidly evolving business landscape, companies are constantly seeking ways to optimize their warehouse operations. As the demand for efficiency, safety, and cost-effectiveness increases, warehouse managers are turning to innovative solutions to stay ahead of the competition. One such solution that has been gaining popularity is the use of Automated Guided Vehicles (AGVs).

The Rise of AGVs

AGVs have revolutionized the way warehouses operate by providing a reliable and efficient means of transportation within the facility. These autonomous vehicles are guided by advanced technology, including sensors, cameras, and navigation systems, allowing them to navigate through the warehouse and perform various tasks with minimal human intervention. AGVs are versatile and can handle a wide range of materials, from pallets and racks to individual items.

Enhancing Safety

Safety is a top priority in any warehouse setting. Manual material handling can be hazardous, with the risk of accidents, injuries, and damage to goods. With AGVs, the risk of human error is significantly reduced, minimizing the chances of workplace accidents. AGVs are equipped with sensors that detect obstacles and adjust their path accordingly, ensuring a safe navigation route. Additionally, they are designed to operate smoothly and efficiently, eliminating sudden stops or jerking movements that can cause damage to goods or equipment.

By implementing AGVs, warehouse managers can create a safer work environment, protecting their employees and reducing the likelihood of costly accidents and injuries. This not only improves workplace morale but also helps companies comply with safety regulations and minimize liability.

Boosting Productivity and Efficiency

One of the key benefits of AGVs is their ability to increase productivity and efficiency within warehouse operations. These autonomous vehicles can work around the clock, without the need for breaks or rest, ensuring continuous operation and maximizing productivity. By automating routine tasks such as material transportation, AGVs free up human workers to focus on more complex and value-added activities.

AGVs can be programmed to follow optimized routes, minimizing travel time and maximizing efficiency. They can also be integrated with warehouse management systems, enabling seamless coordination with other automated processes such as inventory management and order fulfillment. This integration streamlines operations, reduces errors, and improves overall productivity.

Furthermore, AGVs can handle repetitive tasks with precision and consistency, eliminating the variations and inefficiencies that may occur with human workers. This level of accuracy not only improves operational workflows but also leads to higher customer satisfaction and fewer returns.

Cost-Effectiveness in Warehouse Operations

Implementing AGVs can have significant cost-saving benefits for warehouses. While the initial investment may seem substantial, the long-term cost savings outweigh the upfront expenses. AGVs eliminate the need for manual material handling equipment, such as forklifts, reducing maintenance, and repair costs. Furthermore, AGVs are designed to be energy-efficient, resulting in lower utility bills compared to traditional equipment.

Additionally, AGVs help minimize material damage and loss by handling goods with precision and care. This reduces the cost of replacing damaged items and ensures the quality of products throughout their journey within the warehouse. AGVs also contribute to better space utilization, as they can navigate tight spaces and operate in vertical storage systems, allowing warehouses to optimize their layout and storage capacity.

AGVs can also help companies avoid costly labor-related issues such as overtime pay, employee turnover, and training expenses. By automating repetitive tasks, companies can reduce the number of human workers required for these activities, saving on labor costs.

Overall, AGVs play a pivotal role in enhancing innovation and development within warehouse operations. They enable companies to create safer work environments, improve productivity and efficiency, and achieve cost-effectiveness. At HCO Innovations, we specialize in providing warehouse optimization solutions, including AGV deployment. To learn more about our services, visit our website.