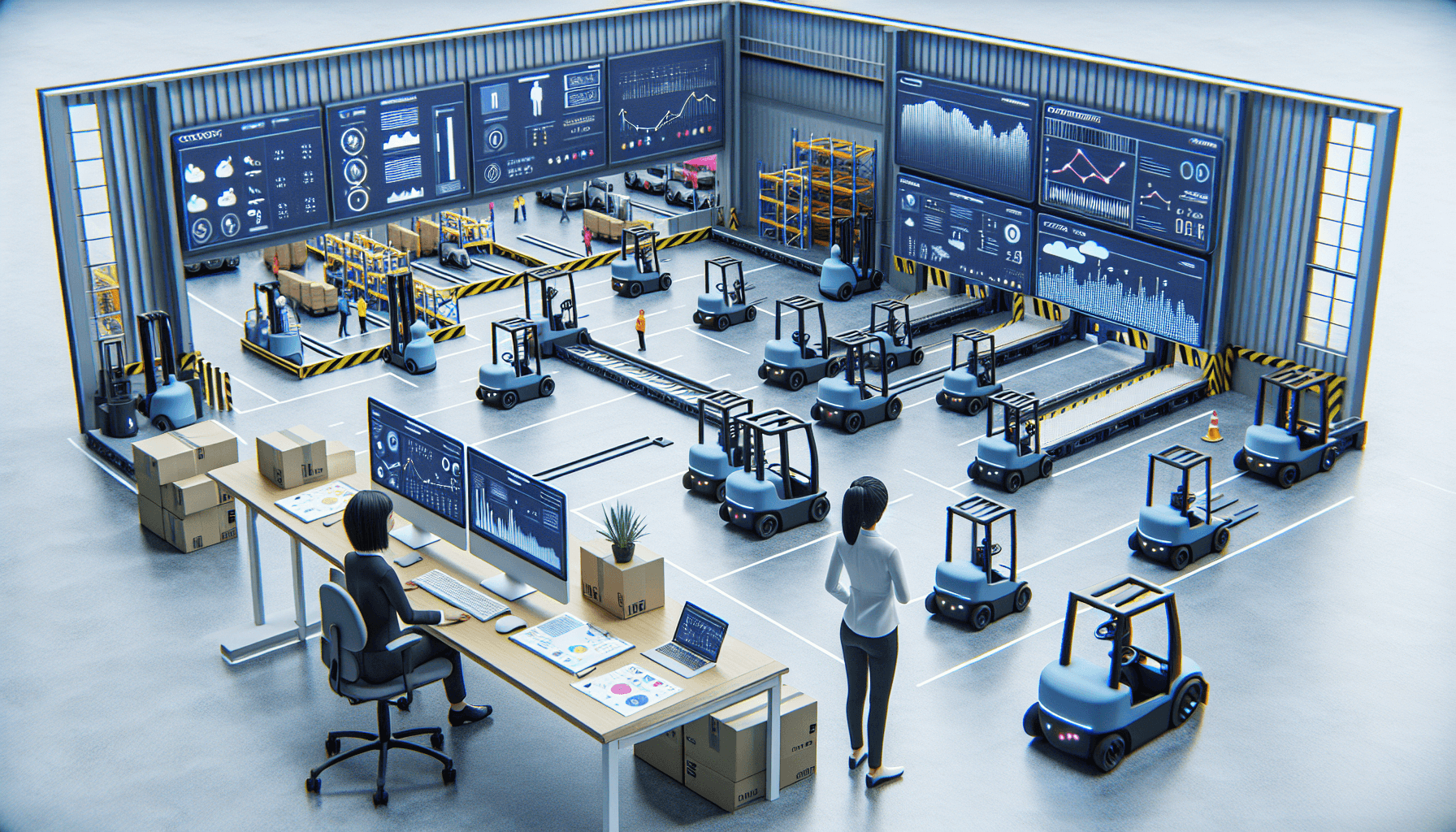

Are you looking to optimize your AGV fleet operations? Look no further! HCO Innovations, a prominent provider of warehouse optimization solutions based in Raleigh, NC, has all the expertise and tools you need to streamline and enhance the performance of your AGV fleet. In this article, we will explore the various strategies and best practices to optimize your AGV fleet operations, ensuring safety, productivity, and efficiency in your warehouse.

1. Efficient Route Planning

One of the key factors in optimizing AGV fleet operations is efficient route planning. HCO Innovations offers advanced software solutions that can analyze your warehouse layout and create optimized routes for your AGVs. By considering factors such as distance, traffic congestion, and product priorities, these software solutions can guide your AGVs to take the most efficient paths, minimizing travel time and maximizing productivity.

Moreover, HCO Innovations’ route planning software is constantly updated to adapt to any changes in your warehouse layout or product placement, ensuring that your AGVs always follow the most optimal routes.

2. Real-Time Monitoring and Analytics

Effective monitoring and analytics are crucial for optimizing AGV fleet operations. HCO Innovations provides cutting-edge monitoring systems that allow you to track the performance of your AGVs in real-time. These systems provide detailed insights into metrics such as travel time, task completion rates, and error rates, enabling you to identify bottlenecks and inefficiencies in your operations.

With HCO Innovations’ analytics tools, you can generate comprehensive reports and visualize key performance indicators. This data-driven approach empowers you to make informed decisions regarding AGV deployment, route optimization, and resource allocation.

3. Fleet Synchronization

AGV fleet synchronization is another critical aspect of optimizing operations. HCO Innovations offers solutions that enable seamless communication and coordination among AGVs, ensuring efficient task allocation and minimizing idle time.

Through centralized control systems, you can assign tasks to AGVs based on their availability, proximity, and capabilities. This synchronized approach prevents duplication of efforts and ensures that resources are utilized optimally, maximizing productivity and reducing operational costs.

4. Safety Enhancements

When it comes to AGV fleet operations, safety is of paramount importance. HCO Innovations specializes in implementing safety enhancements that minimize the risk of accidents and injuries in your warehouse.

With advanced collision avoidance systems and obstacle detection technology, HCO Innovations ensures that your AGVs can navigate the warehouse environment safely. These systems use sensors and cameras to detect potential hazards and automatically adjust AGV paths to avoid collisions. Additionally, alarms and warning signals alert nearby personnel to take necessary precautions.

5. Continuous Improvement through Data Analysis

To truly optimize your AGV fleet operations, it is essential to embrace a culture of continuous improvement. HCO Innovations emphasizes the importance of data analysis and process optimization. By collecting and analyzing data from AGV operations, you can identify areas for improvement and implement targeted changes to enhance efficiency.

Through regular performance reviews and feedback loops, HCO Innovations works with you to refine and fine-tune your AGV fleet operations. Whether it is modifying routes, adjusting task priorities, or upgrading AGV capabilities, the goal is to continuously optimize your operations and adapt to changing business needs.

With HCO Innovations’ comprehensive warehouse optimization solutions and expertise, you can transform your AGV fleet operations and unlock their full potential. Maximizing safety, productivity, and efficiency in your warehouse not only improves your bottom line but also enhances customer satisfaction through timely and accurate order fulfillment. So, why wait? Explore HCO Innovations’ AGV deployment solutions here and take your warehouse operations to the next level!