Warehouse operations are at the heart of any business that handles physical inventory. From managing inventory levels to fulfilling orders, the efficiency and cost-effectiveness of warehouse operations directly impact a company’s bottom line. That’s where HCO Innovations comes in. As a prominent provider of warehouse optimization solutions, they specialize in enhancing safety, productivity, efficiency, and ultimately, cost-effectiveness within warehouse operations.

The Growing Importance of Warehouse Cost Efficiency

In today’s competitive landscape, companies are constantly seeking ways to streamline their operations and reduce costs. Warehouse cost efficiency plays a crucial role in achieving this goal. By optimizing various aspects of their warehouse operations, businesses can significantly enhance their profitability and maintain a competitive edge.

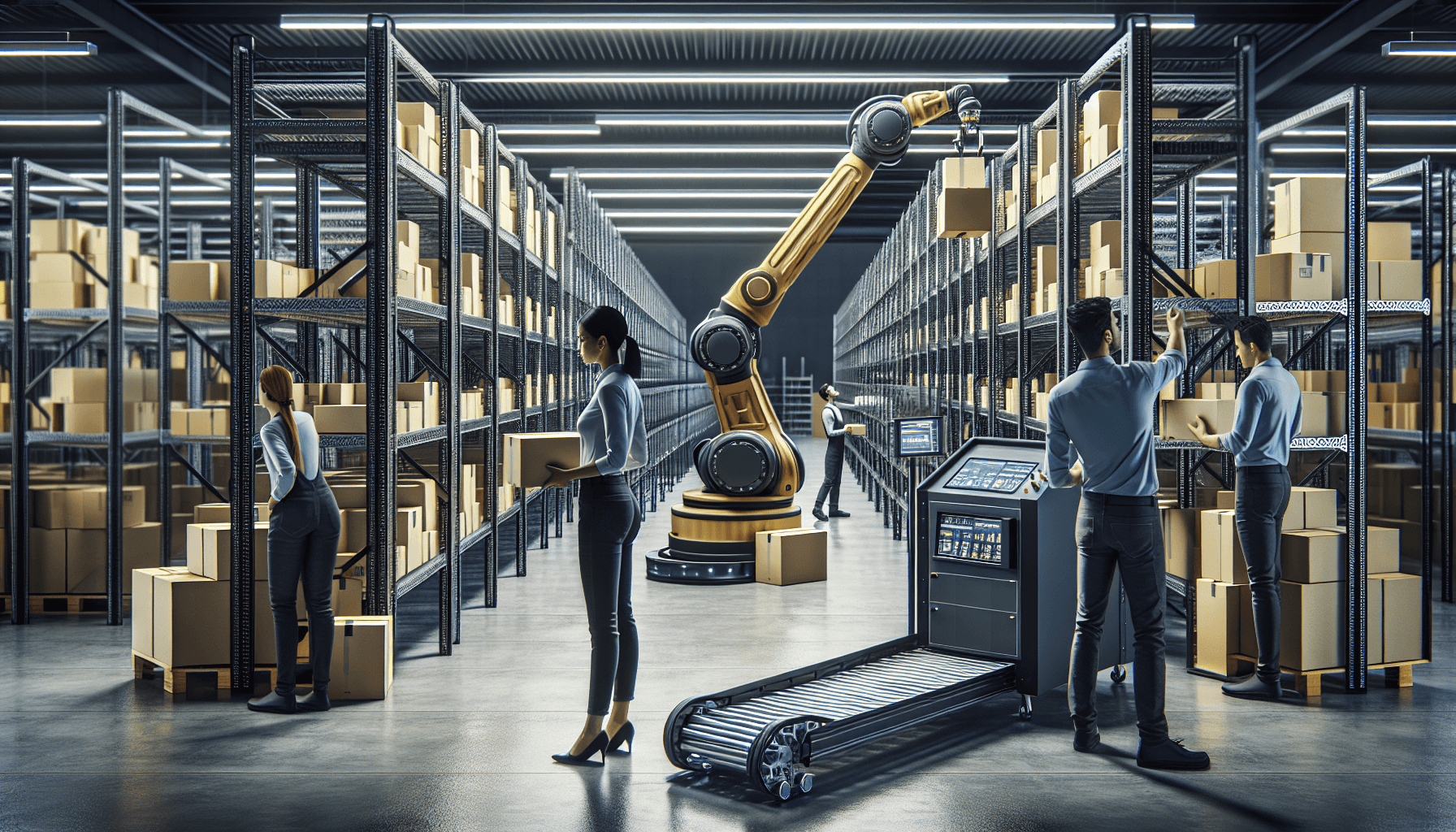

One of the key factors in warehouse cost efficiency is the role of robotics. Over the years, robotics has revolutionized the way warehouses operate, making processes faster, safer, and more efficient. Let’s explore the significant benefits that robotics brings to warehouse operations:

1. Enhanced Productivity

Robots are capable of performing repetitive tasks at a much higher speed and accuracy than human workers. Whether it’s picking, packing, or inventory management, robots can complete these tasks with precision, reducing the margin for error. This increased speed and accuracy translate into enhanced productivity levels within the warehouse. With robots handling mundane and time-consuming tasks, human workers can focus on more strategic and value-added activities, contributing to overall productivity gains.

2. Improved Efficiency

Efficiency is a critical component of warehouse cost optimization. Robots can operate 24/7 without experiencing fatigue or downtime, ensuring continuous workflow within the warehouse. They can also navigate through the warehouse space more efficiently, utilizing the available space to its maximum potential. By streamlining processes and reducing operational inefficiencies, warehouses can improve their overall efficiency, leading to cost savings.

3. Enhanced Safety

Warehouse accidents can have severe consequences for both employees and the company. The integration of robotics in warehouse operations helps mitigate safety risks. Robots are designed to work alongside human workers, helping prevent accidents and reducing the risk of injuries. They can handle heavy lifting and perform repetitive tasks that can strain human workers’ bodies, thereby minimizing the risk of musculoskeletal disorders.

Additionally, robots are equipped with advanced sensors and AI capabilities, allowing them to detect and navigate around obstacles, minimizing the chance of collisions. The improved safety levels contribute to a healthier and more secure work environment.

4. Accurate Inventory Management

Inventory management is a critical aspect of warehouse operations and directly impacts cost efficiency. Errors in inventory tracking can lead to stockouts or excess inventory, both of which can result in financial losses. Robots equipped with advanced scanning technologies can accurately track inventory levels, ensuring real-time visibility. This accurate inventory management enables businesses to optimize stock levels, reduce carrying costs, and prevent stockouts, ultimately improving cost efficiency.

5. Cost Savings

Integrating robotics into warehouse operations may require an initial investment, but the long-term cost savings are substantial. By improving productivity, efficiency, and accuracy, businesses can reduce labor costs and minimize operational expenses. With optimized warehouse operations, companies can also better utilize their space, avoiding the need for expansion or additional facilities, saving on real estate costs. The overall cost savings contribute to a healthier bottom line and increased profitability.

HCO Innovations understands the significance of robotics in warehouse cost efficiency. Their warehouse optimization solutions leverage cutting-edge robotics technology to help businesses achieve their cost optimization goals. With extensive experience and expertise in the field, HCO Innovations offers tailored solutions that address specific warehouse needs, ensuring maximum productivity and cost savings.

If you’re looking to optimize your warehouse operations and improve cost efficiency, HCO Innovations can assist you. Their expertise in warehouse optimization will help you streamline processes, enhance productivity, and ultimately achieve your cost optimization objectives. To learn more about their warehouse cost analysis solutions, click here.

In conclusion, robotics plays a pivotal role in enhancing warehouse cost efficiency. The benefits of incorporating robotics into warehouse operations are multifold, ranging from enhanced productivity and efficiency to improved safety and accurate inventory management. Companies that harness the power of robotics in their warehouses stand to gain a competitive edge by reducing costs and achieving optimal performance.

What is the role of robotics in warehouse cost efficiency?

Robotics play a crucial role in warehouse cost efficiency by automating various tasks such as picking, packing, and sorting of items. With the help of robots, warehouses can achieve higher productivity, reduced labor costs, and faster order processing times.

How do robots contribute to reducing labor costs in warehouses?

Robots can perform repetitive and physically demanding tasks that would otherwise require human workers. This reduces the need for manual labor, leading to cost savings in terms of wages, benefits, and employee turnover.

Can robots improve accuracy and reduce errors in warehouse operations?

Yes, robots are designed to work with precision and accuracy, which helps in reducing errors in warehouse operations. They can scan barcodes, track inventory levels, and ensure accurate order fulfillment, resulting in improved customer satisfaction and reduced costs related to erroneous shipments or returns.

Are there any specific tasks in warehouses that robots can perform?

Yes, robots can perform various tasks in warehouses, such as item picking, sorting, palletizing, and inventory management. They can navigate through warehouse aisles, identify items, and execute tasks efficiently, contributing to overall cost efficiency.

Will implementing robotics in warehouses lead to job losses?

The introduction of robotics in warehouses may change the nature of certain jobs, but it does not necessarily mean job losses. Instead, it can lead to the reskilling and reallocation of workers to more complex tasks that require human intervention. Additionally, the increased efficiency and productivity resulting from robotics can support business growth and create new job opportunities.

What are the potential challenges in implementing warehouse robotics?

Some challenges in implementing warehouse robotics include the initial investment costs, integration with existing systems, potential resistance from employees, and the need for proper training and maintenance. However, with careful planning and effective change management, these challenges can be addressed, and the benefits of robotics can be realized.

Are warehouses of all sizes suitable for implementing robotics?

While robotics can be implemented in warehouses of varying sizes, the suitability depends on factors such as the volume of operations, budget, and complexity of tasks. Smaller warehouses might choose to implement robotics selectively, focusing on specific areas to reap targeted cost-efficiency benefits.

Can robotics help in optimizing warehouse space and layout?

Yes, robotics can contribute to optimizing warehouse space and layout. They can navigate through narrow aisles and utilize vertical space efficiently, maximizing storage capacity. This can lead to reduced rental or construction costs for additional space and enhance overall cost efficiency.

The Future of Autonomous Vehicles in Urban Transportation.

As technology continues to rapidly evolve, the transportation industry is experiencing a paradigm shift with the rise of autonomous vehicles. These self-driving vehicles are set to revolutionize urban transportation, offering a wide array of benefits and opportunities for cities and their residents.

The Rise of Autonomous Vehicles

Autonomous vehicles, also known as self-driving cars, are vehicles that can operate without human intervention. They are equipped with advanced sensors and artificial intelligence (AI) technology to navigate roads, avoid obstacles, and make intelligent decisions in real-time.

Leading companies in the automotive and technology sectors, such as Tesla, Waymo (owned by Alphabet Inc., Google's parent company), and Uber, are investing heavily in autonomous vehicle development. These companies are conducting extensive research and testing to perfect the technology and ensure its safety and reliability.

HCO Innovations is at the forefront of this wave of innovation, incorporating autonomous vehicle technology into their warehouse optimization and forklift fleet management services. By leveraging the power of self-driving vehicles, HCO Innovations is helping clients streamline their operations, improve efficiency, and reduce costs in managing large warehouses and extensive fleets of forklifts.

The Benefits of Autonomous Vehicles in Urban Transportation

The integration of autonomous vehicles in urban transportation systems holds numerous advantages:

- Enhanced Safety: One of the key advantages of autonomous vehicles is their potential to minimize human error, which is responsible for the majority of road accidents. With their advanced sensors and real-time decision-making capabilities, self-driving cars can help reduce accidents and save lives.

- Traffic Optimization: Autonomous vehicles have the potential to optimize traffic flow by communicating with each other and coordinating their movements. This can help reduce congestion and improve overall traffic efficiency, resulting in shorter travel times and less fuel consumption.

- Environmental Impact: The use of autonomous electric vehicles can significantly reduce greenhouse gas emissions and air pollution. By replacing traditional fuel-powered cars with electric autonomous vehicles, we can take a step towards achieving a sustainable and eco-friendly transportation system.

- Accessibility: Autonomous vehicles can greatly improve accessibility for individuals with limited mobility or disabilities. These self-driving cars can provide reliable and convenient transportation for people who are unable to drive or have difficulty using public transportation.

- Efficient Resource Utilization: With the introduction of autonomous ride-sharing services, fewer vehicles are needed to serve the same number of passengers. This leads to reduced parking space requirements and optimizes the utilization of existing resources, ultimately freeing up valuable urban land.

The Challenges of Implementing Autonomous Vehicles

While the potential benefits of autonomous vehicles are promising, there are still several challenges to overcome for their successful implementation:

- Legal and Regulatory Framework: The establishment of a comprehensive legal and regulatory framework is necessary to address liability issues, ensure public safety, and establish guidelines for the operation of autonomous vehicles on public roads.

- Cybersecurity: As autonomous vehicles rely heavily on advanced software and AI systems, they are vulnerable to cybersecurity threats. Ensuring the security and integrity of these vehicles' systems is crucial to prevent hacking attempts and safeguard passenger safety.

- Public Acceptance: Widespread public acceptance and trust in autonomous vehicles are essential for their successful integration into urban transportation systems. Educating the public about the benefits and safety measures of self-driving cars is crucial to overcome skepticism and gain widespread support.

- Infrastructure Development: The infrastructure needs to be upgraded to support autonomous vehicles. This includes the installation of appropriate charging stations for electric autonomous vehicles and the integration of advanced technology to enable efficient communication between vehicles and infrastructure.

- Job Displacement: The rise of autonomous vehicles may lead to job displacement for individuals working in the transportation industry. Adequate measures need to be taken to address this issue by providing retraining programs and creating new job opportunities in emerging sectors.

The Future is Autonomous

Despite the challenges, the future of autonomous vehicles in urban transportation looks promising. As technology continues to advance and regulations catch up, we can expect to see self-driving cars become a common sight on city streets.

Firms like HCO Innovations are at the cutting edge of this technological revolution, incorporating autonomous vehicle technology into their warehouse optimization solutions. By utilizing self-driving forklifts and other autonomous vehicles within the warehouse environment, companies can achieve higher levels of efficiency, productivity, and safety.

With their expertise in warehouse layout evaluation, safety assessments, and turnkey maintenance solutions, HCO Innovations is helping businesses across a variety of industries achieve significant cost reductions and operational efficiency. By leveraging advanced cost-tracking software and their collaborative "boots on the ground" approach, HCO Innovations ensures their tailored solutions consistently deliver exceptional return on investment.

As we embrace the future of autonomous vehicles, it's clear that companies like HCO Innovations are leading the way in optimizing warehouse operations and reducing material handling costs. Through their innovative solutions and dedication to excellence, they are revolutionizing not only urban transportation but also the way businesses manage their logistics and operations.