In today’s competitive business landscape, warehouse operations play a crucial role in the overall success of a company. A well-designed warehouse layout can significantly impact safety, productivity, efficiency, and cost-effectiveness. One popular approach to optimize warehouse layouts is through zoning. This article will explore the benefits of implementing a zoned warehouse layout and how HCO Innovations can help businesses achieve their warehouse optimization goals.

What is a Zoned Warehouse Layout?

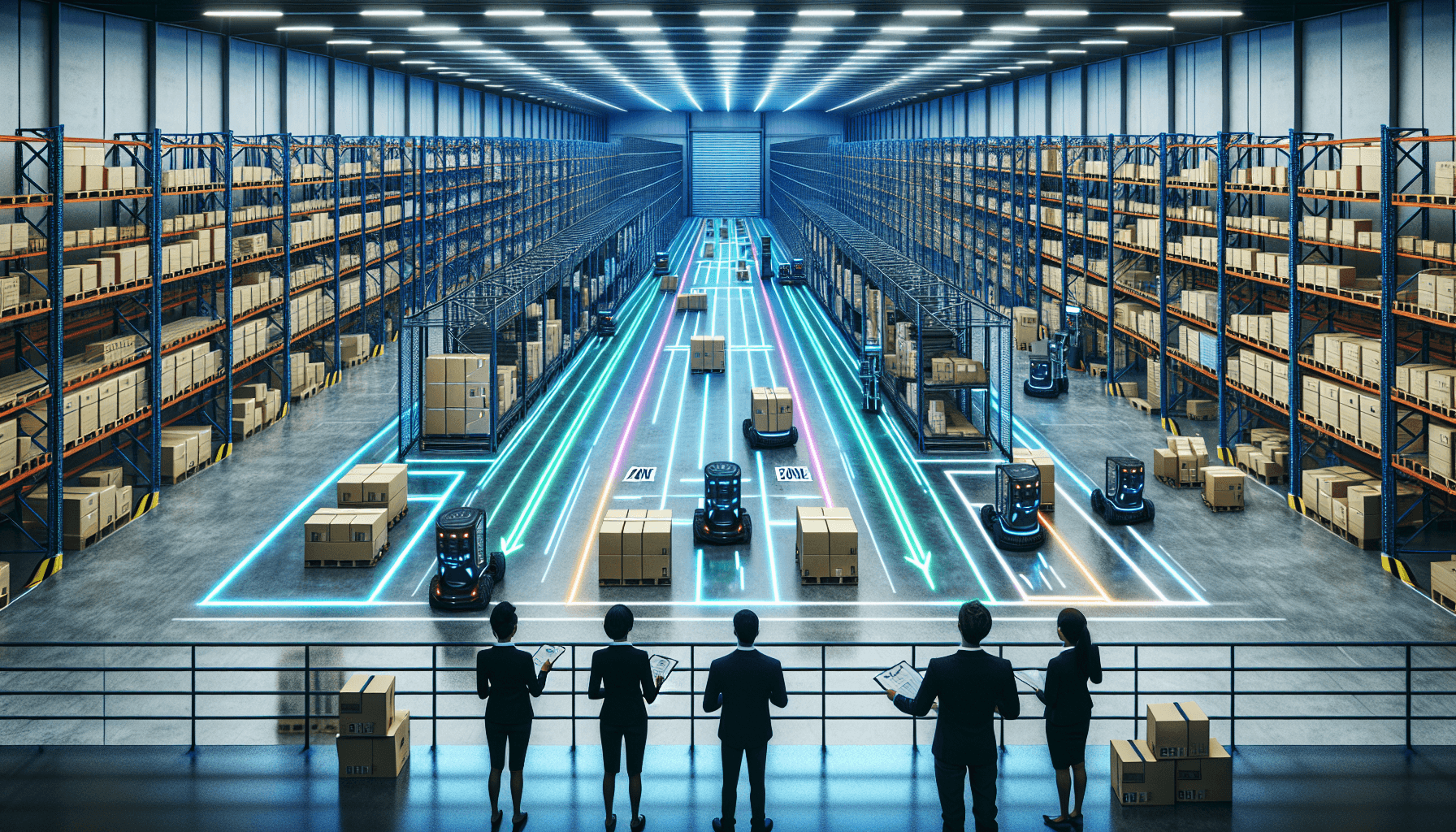

A zoned warehouse layout involves dividing the warehouse space into distinct zones or areas based on specific criteria such as product type, velocity, storage requirements, or process flow. Each zone is strategically designed to cater to specific activities and optimize operational efficiency. This approach allows for streamlined processes, improved inventory management, and increased productivity.

By leveraging a zoned warehouse layout, businesses can enhance the overall performance of their warehouse operations. Let’s explore some of the key benefits:

1. Increased Efficiency

One of the primary benefits of a zoned warehouse layout is improved efficiency. By having designated areas for different tasks, such as receiving, picking, packing, and shipping, employees can work more efficiently and minimize unnecessary movement. This reduces travel time, improves order fulfillment speed, and ultimately increases customer satisfaction.

HCO Innovations understands the importance of efficiency in warehouse operations. Through their expertise in warehouse optimization solutions, they can analyze your current warehouse layout and implement a zoned approach that maximizes efficiency and minimizes bottlenecks.

2. Enhanced Safety

A zoned warehouse layout can also significantly improve safety within the warehouse. By separating areas for different activities, the risk of accidents and collisions between workers, forklifts, and other equipment is minimized. Additionally, clearly marked zones and designated routes ensure that employees can navigate the warehouse safely, reducing the chances of injuries or material damage.

HCO Innovations prioritizes safety in their warehouse optimization solutions. They can assist in identifying potential hazards in your warehouse layout and implementing safety measures to mitigate risks. Their expertise in warehouse safety can help create a secure working environment for your employees.

3. Optimal Space Utilization

With a zoned warehouse layout, businesses can optimize their space utilization. Each zone is designed to accommodate specific products or processes, allowing for better organization and utilization of available space. This helps maximize storage capacity and reduces the need for excessive aisle space, resulting in increased storage density.

HCO Innovations specializes in space optimization solutions. By analyzing your warehouse layout and considering factors such as product volume and velocity, they can help you create a zoned layout that maximizes your space utilization and optimizes your storage capacity.

4. Streamlined Workflow

Implementing a zoned warehouse layout facilitates a more streamlined workflow. Each zone is assigned specific tasks and processes, creating a logical flow from one area to another. This eliminates unnecessary backtracking and improves overall process efficiency. By minimizing the distance traveled and simplifying the workflow, businesses can achieve higher throughput and reduce operational costs.

With their experience in warehouse optimization, HCO Innovations can help you design a zoned layout that aligns with your unique workflow requirements. By considering factors such as the order of operations and process dependencies, they can create a layout that enhances your workflow and drives operational excellence.

In conclusion, a zoned warehouse layout offers various benefits such as increased efficiency, enhanced safety, optimal space utilization, and streamlined workflow. By partnering with HCO Innovations, businesses can leverage their expertise in warehouse optimization to create a customized, zoned layout that optimizes their warehouse operations.

Are you interested in optimizing your warehouse layout? Contact HCO Innovations for a warehouse layout evaluation and let their team of experts guide you towards achieving a more efficient and cost-effective warehouse operation. Visit https://www.hcoinnovations.com/warehouse-layout-evaluation/ to learn more.