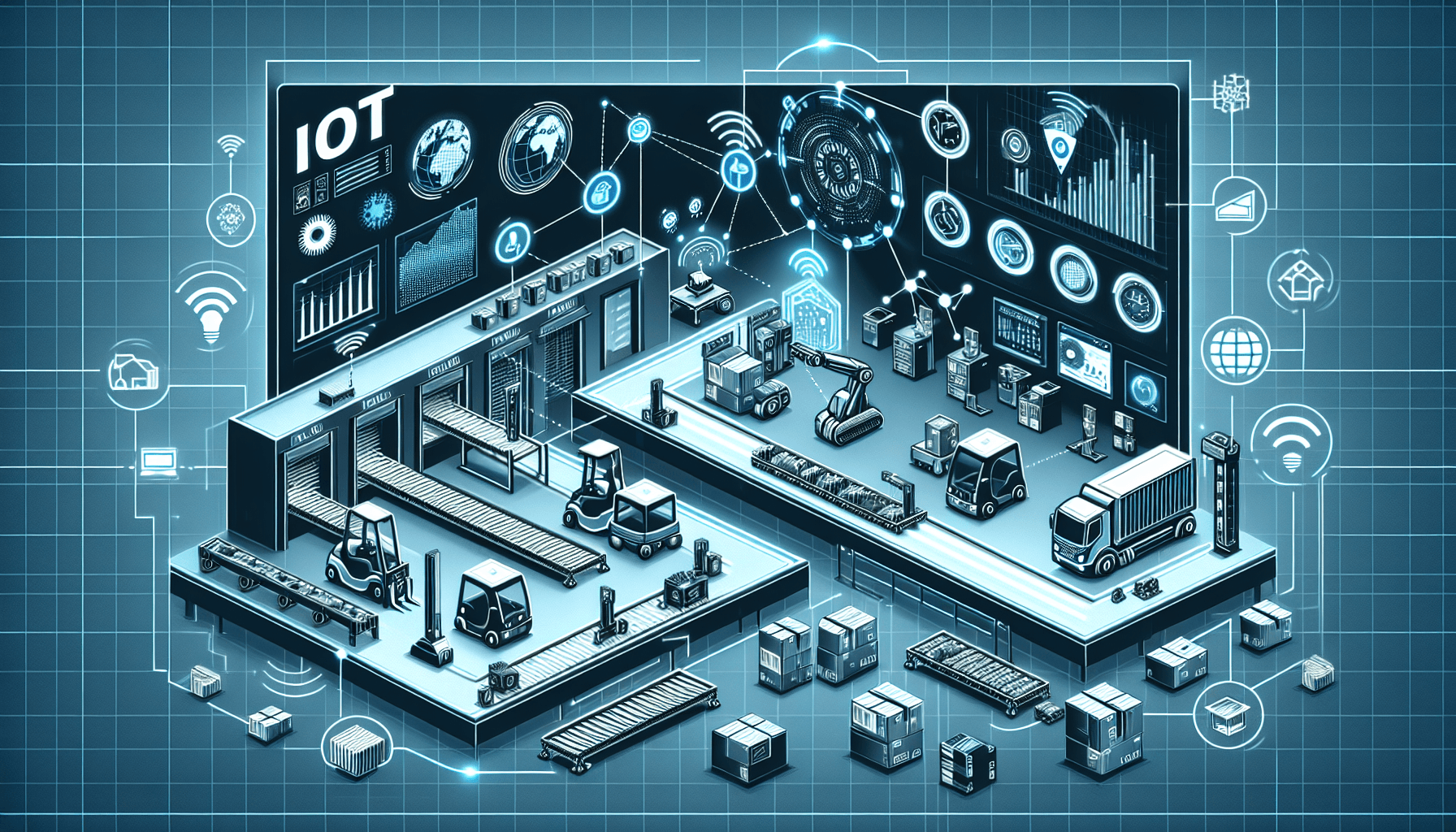

With the ever-evolving landscape of warehouse operations, it becomes crucial for businesses to seek innovative solutions that enhance safety, productivity, efficiency, and cost-effectiveness. One of the transformative technologies that have revolutionized the warehouse industry is the Internet of Things (IoT).

The Impact of IoT on Material Flow Management

The efficient management of material flow is a key component of warehouse optimization. It involves the movement of goods through various stages of the supply chain, from receiving to storage, picking, packing, and shipping. Traditionally, these processes required manual labor and were prone to errors and inefficiencies. However, with the implementation of IoT in warehouse operations, material flow management has reached new heights of efficiency and effectiveness.

The IoT refers to a network of interconnected devices embedded with sensors, software, and connectivity, enabling them to collect and exchange data. In the context of warehouse operations, IoT devices include sensors, RFID tags, beacons, and other smart devices that gather real-time data on inventory, equipment, and environmental conditions. This data can then be analyzed and used to optimize material flow management.

One of the significant advantages of IoT in material flow management is improved visibility and tracking. By deploying IoT devices throughout the warehouse, businesses can gain real-time insights into the exact location and status of each item in their inventory. This eliminates the need for manual tracking, reduces the risk of errors, and allows for prompt decision-making.

Furthermore, the IoT enables businesses to automate various processes in material flow management. For instance, IoT-enabled sensors can monitor inventory levels and automatically trigger replenishment orders when stock reaches a certain threshold. This automation reduces manual intervention, streamlines operations, and prevents stockouts, ultimately contributing to improved customer satisfaction.

The utilization of IoT in material flow management also enhances safety within the warehouse. With real-time data on environmental conditions such as temperature, humidity, and air quality, businesses can proactively address any potential risks or hazards. This ensures the quality and integrity of products and protects the well-being of warehouse personnel.

Another notable benefit of IoT is predictive maintenance. By equipping equipment and machinery with sensors, businesses can monitor their performance in real-time and detect any anomalies or signs of malfunction. This allows for proactive maintenance and reduces the likelihood of unexpected breakdowns or costly repairs. Ultimately, predictive maintenance helps optimize uptime, extend the lifespan of equipment, and minimize operational disruptions.

It is also important to highlight the role of data analytics in optimizing material flow management through IoT. The vast amount of data collected by IoT devices can be processed and analyzed to identify patterns, trends, and areas for improvement. By leveraging advanced analytics and machine learning algorithms, businesses can gain actionable insights to optimize workflows, reduce bottlenecks, and optimize resource allocation.

However, it is crucial for businesses to carefully plan and implement IoT solutions for material flow management. This involves considering factors such as the compatibility of existing systems, the scalability of IoT infrastructure, and cybersecurity measures to protect sensitive data.

At HCO Innovations, we recognize the immense potential of IoT in transforming warehouse operations. With our expertise in warehouse optimization, we can assist businesses in harnessing the power of IoT for material flow management. Our team of professionals can conduct a comprehensive material flow evaluation, identifying opportunities for improvement and implementing tailored IoT solutions to streamline operations and drive business growth.

If you are interested in enhancing your warehouse’s material flow management with IoT, contact us today to schedule a consultation.

In conclusion, the integration of IoT in material flow management brings numerous benefits to warehouse operations. From improved visibility and tracking to automation, safety enhancements, predictive maintenance, and data analytics, IoT revolutionizes the way businesses optimize their material flow processes. By leveraging the power of IoT, businesses can enhance productivity, efficiency, and cost-effectiveness, ultimately gaining a competitive edge in the rapidly evolving warehouse industry.

What is IoT and how does it relate to material flow management?

IoT stands for Internet of Things, which refers to the network of physical devices connected to the internet and capable of collecting and exchanging data. In material flow management, IoT plays a crucial role by enabling real-time monitoring, data analytics, and automation of processes, leading to improved efficiency, visibility, and control over the entire material flow.

How can IoT improve inventory management in material flow?

By deploying IoT sensors and devices, companies can track inventory in real-time, automate stock replenishment, and receive alerts for low stock levels. This helps in minimizing inventory holding costs, reducing stockouts, and optimizing the procurement process to ensure smooth material flow management.

What are the benefits of implementing IoT in material flow management?

Implementing IoT in material flow management brings numerous benefits, including increased efficiency, reduced wastage, improved transparency, accurate demand forecasting, enhanced traceability, proactive maintenance, and better decision-making based on accurate, real-time data.

Can IoT help in optimizing logistical operations in material flow management?

Absolutely! IoT provides real-time tracking and monitoring of assets, vehicles, and shipments. This promotes efficient route planning, minimizes delays, optimizes delivery schedules, and reduces transportation costs. IoT-enabled logistics in material flow management ensure efficient and timely movement of goods across the supply chain.

What security and data privacy considerations should be taken into account when implementing IoT in material flow management?

When implementing IoT in material flow management, it is essential to prioritize security and data privacy. This includes implementing robust authentication and encryption measures, regularly updating firmware and software, securing network connections, and complying with industry regulations to protect sensitive data from unauthorized access and potential cyber threats.

How does IoT help in predictive maintenance in material flow management?

IoT sensors can be utilized to monitor the health and performance of machines, equipment, and systems in real-time. By collecting and analyzing data, IoT enables predictive maintenance, where potential equipment failures or maintenance requirements can be detected in advance. This proactive approach minimizes unplanned downtime, extends equipment lifespan, and ensures optimal performance for smooth material flow management.

The Benefits of RFID Technology for Inventory Management.

In today's fast-paced business world, efficient inventory management is crucial for a company's success. Without proper control and visibility of inventory, businesses can face costly errors, stockouts, and customer dissatisfaction. Fortunately, advancements in technology have revolutionized the way inventory is managed, and one such technology is RFID (Radio Frequency Identification).

What is RFID Technology?

RFID technology utilizes radio waves to capture and transmit data from RFID tags attached to inventory items. These tags contain electronically stored information that can be read using RFID readers or scanners. Unlike traditional barcode systems, RFID does not require direct line-of-sight scanning, making it faster and more efficient.

RFID tags are typically attached to individual items, cartons, or pallets, allowing for real-time tracking and management. The tags can store a range of information, including unique serial numbers, product details, expiration dates, and more. This technology has proven to be invaluable for warehouse optimization and inventory management.

The Benefits of RFID Technology for Inventory Management:

Implementing RFID technology for inventory management can bring numerous benefits to businesses of all sizes. Let's explore some of the key advantages:

1. Improved Accuracy:

RFID technology offers enhanced accuracy compared to traditional inventory management methods. With RFID, items can be quickly scanned without the need for manual entry or line-of-sight scanning. This reduces human error and ensures that inventory counts are more precise. The real-time data provided by RFID enables better inventory visibility, reducing the risk of stockouts or overstock situations.

2. Increased Efficiency:

RFID technology enables quick and efficient inventory management processes. With RFID tags, inventory items can be scanned in bulk, drastically reducing the time required for manual inventory counts. Additionally, RFID tags can be read from a distance, allowing for faster and more seamless inventory tracking and reconciliation. This increased efficiency translates to cost savings and improved overall operational productivity.

3. Enhanced Visibility and Traceability:

RFID technology provides businesses with real-time visibility and traceability of inventory. With RFID tags on individual items or pallets, businesses can track the movement of inventory throughout the entire supply chain. This level of visibility allows for better planning, demand forecasting, and inventory replenishment. It also helps in ensuring product authenticity and quality control.

4. Streamlined Operations:

By utilizing RFID technology, businesses can streamline their inventory management processes. Real-time inventory data allows for accurate demand forecasting and proactive replenishment. Automated data capture eliminates the need for manual data entry, reducing labor costs and minimizing the likelihood of errors. This streamlining of operations leads to increased operational efficiency and better overall inventory control.

5. Improved Customer Experience:

RFID technology enables businesses to provide a seamless and efficient customer experience. Real-time inventory data ensures that products are always available when customers need them, reducing the risk of stockouts. Additionally, RFID can be utilized in conjunction with other technologies like electronic shelf labels or self-checkout systems, further enhancing the customer experience. Satisfied customers are more likely to become repeat customers, leading to increased customer loyalty and revenue.

Conclusion

RFID technology offers numerous benefits for inventory management, ranging from improved accuracy and efficiency to enhanced visibility and streamlined operations. By leveraging RFID technology, businesses can achieve better control over their inventory, reduce costs, and provide a superior customer experience. HCO Innovations, a leading management consulting firm based in Raleigh, North Carolina, can assist your company in implementing RFID technology for optimized warehouse operations and inventory management. Their expertise in warehouse optimization and forklift fleet management, coupled with advanced cost-tracking software and a collaborative approach, makes them the trusted partner you need. To learn more about their services, visit HCO Innovations.