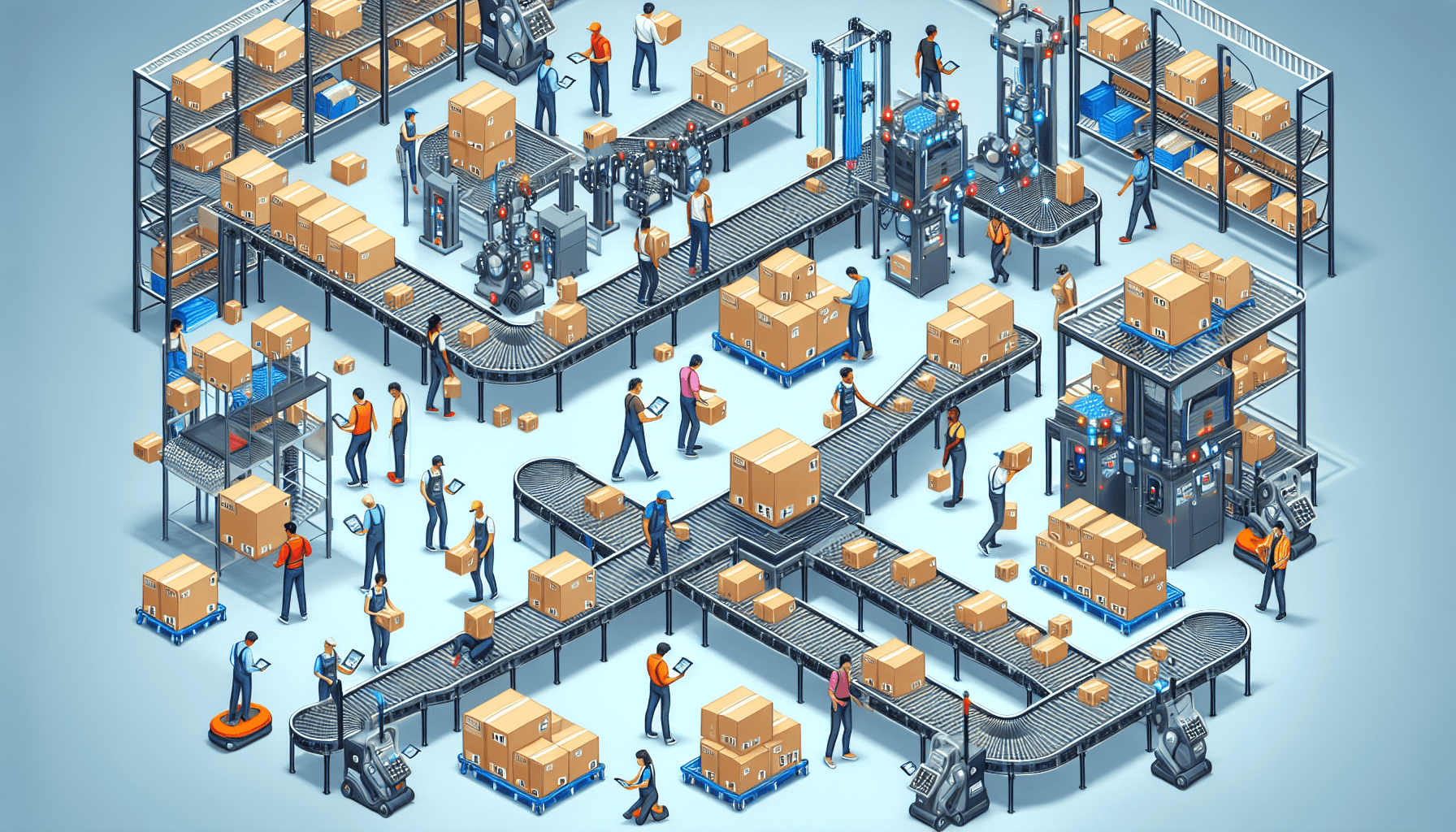

The success of a warehouse operation greatly depends on its efficiency, productivity, and cost-effectiveness. To achieve these goals, warehouse managers need to focus on optimizing their warehouse networks. Warehouse network optimization involves the systematic analysis and improvement of various factors such as layout, processes, technology, and resources to ensure smooth operations and maximize performance.

Why Warehouse Network Optimization is Essential

Efficient warehouse network optimization is essential for businesses for several reasons:

- Improved Efficiency: By optimizing the warehouse network, businesses can streamline their operations, reduce time wasted on inefficient processes, and increase overall productivity. This leads to faster order fulfillment and better customer satisfaction.

- Reduced Costs: A well-optimized warehouse network helps in reducing operational costs by saving time, minimizing inventory carrying costs, optimizing space utilization, and eliminating unnecessary expenses.

- Enhanced Safety: Warehouse network optimization includes evaluating safety protocols and implementing measures to mitigate potential hazards. This ensures a safer working environment for employees, reducing the risk of accidents and injuries.

- Scalability: Optimizing the warehouse network allows businesses to easily scale their operations as they grow. It enables efficient handling of increased volumes while maintaining high levels of productivity and customer service.

Key Strategies for Effective Warehouse Network Optimization

Implementing effective warehouse network optimization requires careful planning and strategic implementation. Below are some key strategies that businesses can follow:

- Analyze and Map the Current Network: Start by thoroughly analyzing and mapping out the existing warehouse network. This includes evaluating the layout, processes, storage capacity, and resource allocation. Identify potential bottlenecks, inefficiencies, and areas for improvement.

- Optimize Warehouse Layout: A well-organized warehouse layout plays a critical role in improving efficiency. Optimize the placement of inventory, equipment, and workstations to minimize travel time, reduce congestion, and maximize space utilization. Utilize technology such as warehouse management systems (WMS) to automate and optimize inventory handling.

- Implement Effective Inventory Management: Accurate and efficient inventory management is vital for warehouse network optimization. Implement inventory control measures such as cycle counting, ABC analysis, and real-time inventory tracking to minimize errors, prevent stockouts, and improve order accuracy and fulfillment.

- Upgrade Material Handling Equipment: Investing in modern material handling equipment can greatly enhance warehouse operations. Automated conveyors, forklifts, palletizers, and robotic systems can improve speed, accuracy, and worker safety. Evaluate the current equipment and identify areas where upgrading can enhance productivity.

- Utilize Data and Technology: Leverage data analytics and technology solutions to gain insights into warehouse performance, identify trends, and make informed decisions. Implement a robust warehouse management system (WMS) that can track inventory, monitor productivity, generate reports, and optimize resource allocation.

- Optimize Order Fulfillment Process: Streamline the order fulfillment process to reduce delivery lead times and improve customer satisfaction. Utilize strategies such as batch picking, wave picking, and cross-docking to minimize order processing time and increase throughput.

- Implement Lean Principles: Embrace lean principles such as just-in-time (JIT) inventory management, 5S methodology, and continuous improvement to eliminate waste, reduce costs, and increase operational efficiency. Minimize unnecessary movements, optimize labor allocation, and promote a culture of continuous improvement throughout the organization.

- Collaborate with Supply Chain Partners: Work closely with suppliers, transportation providers, and other supply chain partners to optimize the entire network. Collaborate on demand forecasting, sharing real-time data, and implementing joint improvement initiatives. This ensures better coordination, reduces lead times, and improves overall network efficiency.

- Regularly Review and Fine-tune: Warehouse network optimization is an ongoing process. Regularly review performance metrics, gather feedback from employees, and fine-tune the processes. Continuously look for opportunities to optimize and adapt to changing business needs and market dynamics.

By implementing these key strategies, businesses can achieve significant improvements in warehouse network optimization. However, it is important to recognize that every warehouse operation is unique, and customization based on specific requirements is crucial for success. Partnering with a reputable warehouse optimization solutions provider like HCO Innovations can provide expert guidance and tailored solutions for businesses seeking optimal warehouse performance.

Learn more about how HCO Innovations can help boost your warehouse network optimization efforts, enhance safety, productivity, efficiency, and cost-effectiveness.