In today’s competitive business landscape, customer satisfaction has become a critical factor for the success of any company. Organizations are constantly seeking ways to improve their operations and deliver exceptional customer experiences. One area that has a significant impact on customer satisfaction is warehouse network optimization.

What is Warehouse Network Optimization?

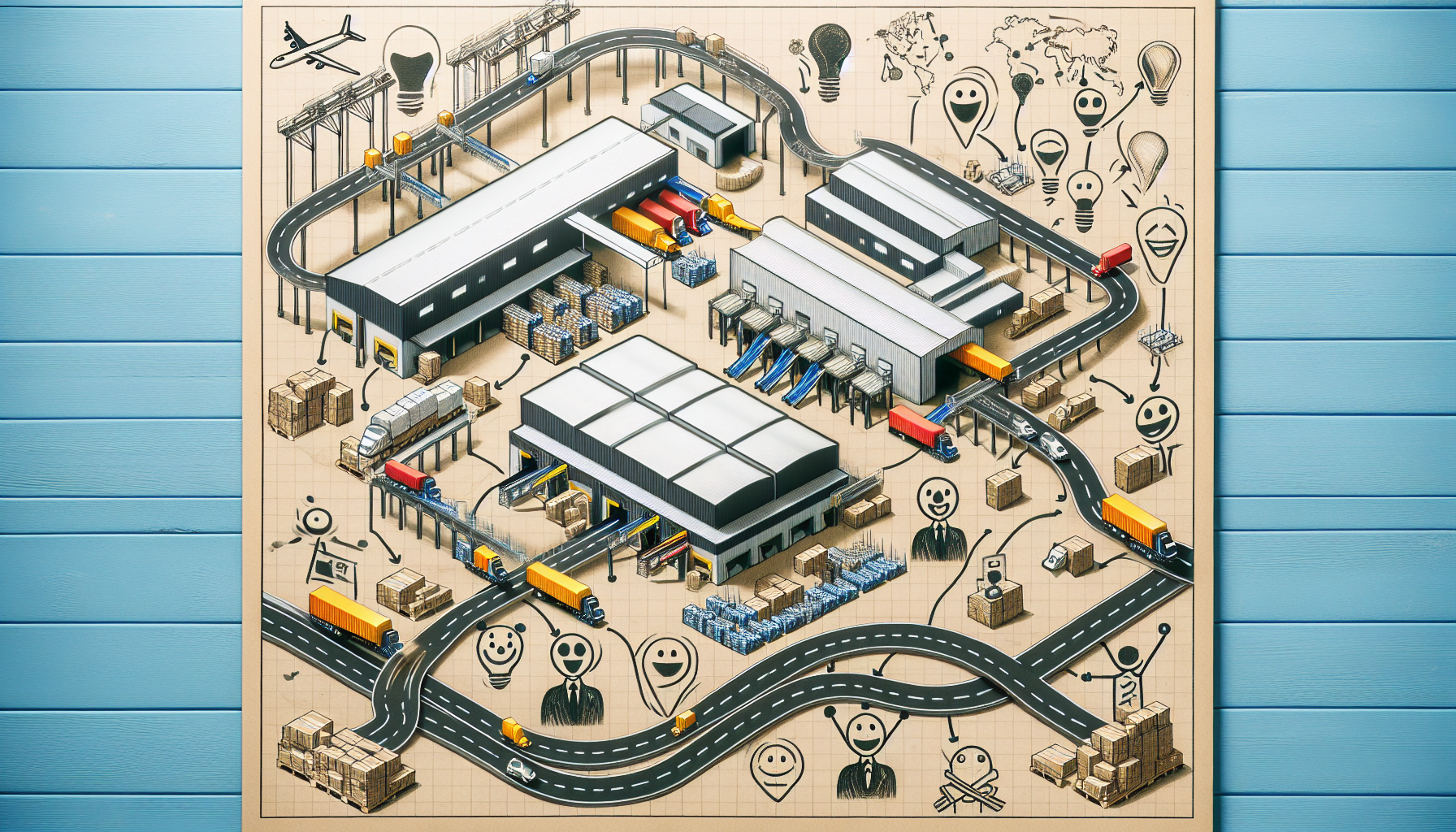

Warehouse network optimization is the process of strategically designing and managing a network of warehouses to enhance efficiency, reduce costs, and improve overall performance. It involves analyzing various factors such as product demand, transportation costs, inventory levels, and customer locations to determine the optimal location, size, and configuration of warehouses within a distribution network.

By implementing an optimized warehouse network, companies can streamline their supply chain operations, improve order fulfillment processes, and ultimately deliver products to customers more efficiently. This translates into shorter lead times, reduced shipping costs, and increased customer satisfaction.

The Impact of Warehouse Network Optimization on Customer Satisfaction

1. Faster Order Processing and Delivery:

An optimized warehouse network allows for faster order processing and delivery. By strategically locating warehouses closer to customer clusters or major transportation hubs, companies can significantly reduce transit times. This ensures that products reach customers in a timely manner, meeting or even exceeding their expectations. Faster order processing and delivery contribute to a positive customer experience, leading to greater satisfaction and loyalty.

2. Improved Inventory Management:

Optimizing the warehouse network helps companies gain better control over their inventory. By strategically distributing inventory across multiple warehouses, companies can avoid stock-outs and overstocks, thereby improving product availability. Customers appreciate having access to a wide range of products and knowing that they can rely on the company to fulfill their orders promptly. This level of reliability and consistency positively impacts customer satisfaction.

3. Enhanced Communication and Visibility:

An optimized warehouse network is often supported by advanced warehouse management systems (WMS) and logistics technology. These systems provide real-time visibility into inventory levels, order statuses, and shipment tracking. When customer service representatives have access to accurate and up-to-date information, they can provide customers with accurate delivery estimates and address any concerns promptly. Improved communication and visibility create a sense of trust and transparency, leading to higher levels of customer satisfaction.

4. Cost Savings Passed onto Customers:

An optimized warehouse network enables companies to reduce transportation costs, inventory holding costs, and operational expenses. These cost savings can be passed onto customers in the form of competitive pricing or better value for money. Customers appreciate when companies offer cost-effective solutions without compromising on quality. By optimizing their warehouse network, companies can gain a competitive edge and enhance customer satisfaction.

5. Efficient Returns and Exchanges Process:

Returns and exchanges are an inevitable part of any business, and how companies handle them can greatly impact customer satisfaction. An optimized warehouse network allows for efficient handling of returns and exchanges by having dedicated warehouses or designated areas for processing these transactions. This ensures faster turnaround times, seamless processes, and a hassle-free experience for customers, ultimately leading to higher levels of satisfaction and customer loyalty.

Visit HCO Innovations to explore how their warehouse optimization solutions can help your company enhance customer satisfaction and boost overall performance.

In Conclusion

Warehouse network optimization plays a crucial role in improving customer satisfaction. By strategically designing, managing, and optimizing their warehouse network, companies can achieve faster order processing and delivery, improved inventory management, enhanced communication and visibility, cost savings passed onto customers, and efficient returns and exchanges processes. Investing in warehouse optimization solutions can lead to happier customers, repeat business, and a competitive advantage in the marketplace.