Warehouse safety is of utmost importance to any business that relies on efficient and proficient operations. One essential aspect of ensuring safety within a warehouse is being prepared for emergencies and unexpected events. This is where safety drills play a crucial role. In this article, we will explore the benefits of safety drills for warehouse preparedness and why they should be a part of every warehouse’s safety protocol.

Enhanced Emergency Response

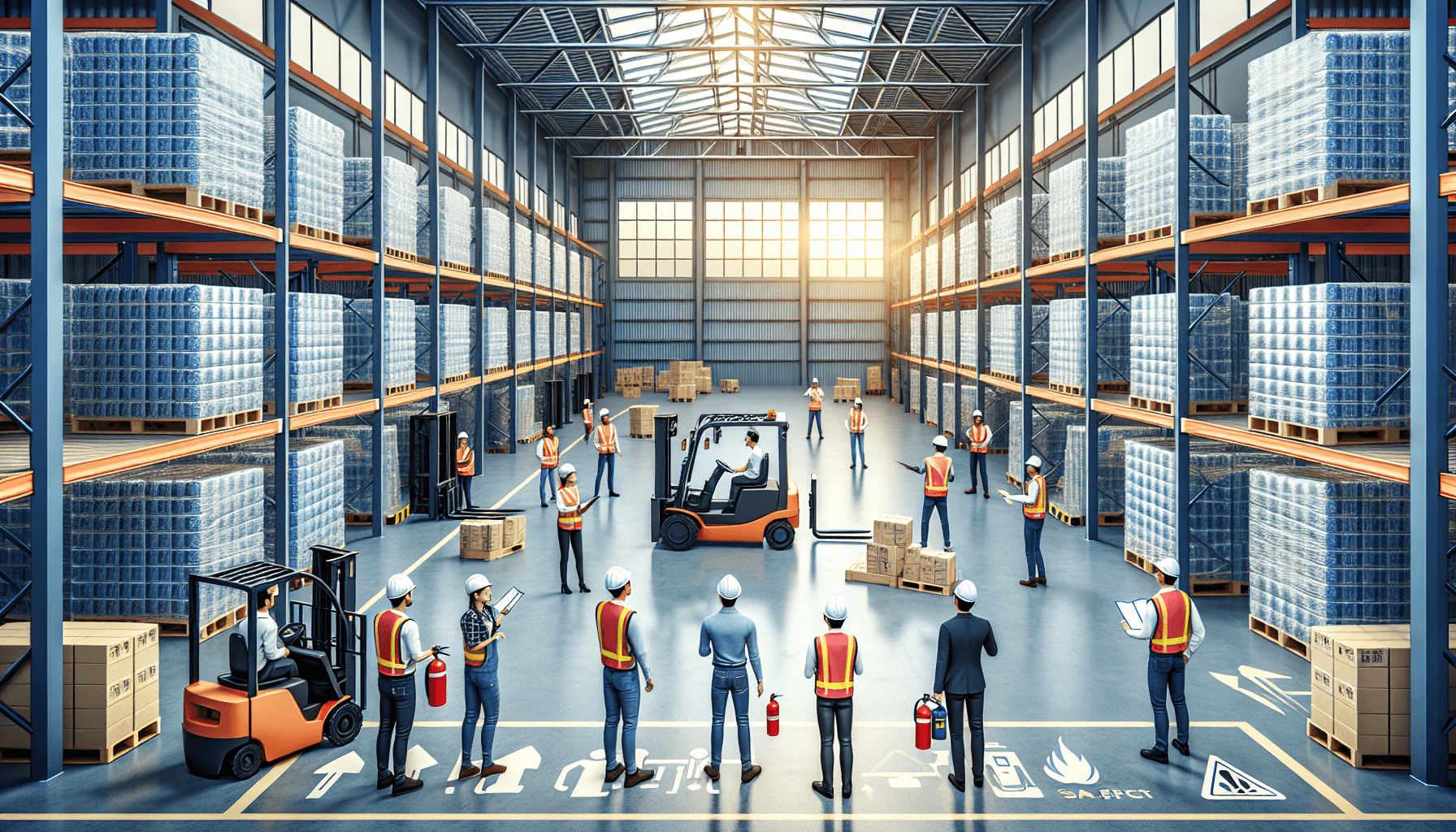

One of the primary benefits of conducting safety drills in a warehouse setting is the enhanced emergency response it provides. Safety drills simulate real-life emergency situations, such as fires, hazardous spills, or power outages, allowing warehouse staff to practice their response protocols in a controlled environment.

By going through these drills, warehouse employees become better prepared to handle emergencies, knowing the necessary steps to take, such as evacuating the premises, contacting emergency services, or using fire extinguishers. This preparedness can significantly reduce response times and help prevent injuries or further damage during an actual emergency.

Warehouse safety evaluations and drills also provide an opportunity to identify any weaknesses or gaps in the emergency response plan. Any shortcomings can be addressed and remedies put in place to ensure that the warehouse is well-prepared to handle any unforeseen circumstances.

Improved Employee Training

Safety drills are not only essential for emergency preparedness, but they also contribute to the overall training and development of warehouse employees. Through drills, employees gain valuable hands-on experience and become more familiar with safety protocols, equipment operation, and evacuation procedures.

Regular safety drills ensure that employees are up to date with the latest safety procedures and protocols. Training sessions can be conducted before or after each drill to reinforce key safety concepts, review any changes or updates to protocols, and address any questions or concerns from the employees.

Moreover, safety drills create a culture of safety within the warehouse. Employees understand the importance of safety, both for themselves and their colleagues, and actively engage in creating a safe working environment. This mindset can lead to a reduction in accidents and injuries, improving overall workplace morale and productivity.

Identifying Operational Improvements

While safety drills mainly focus on emergency preparedness, they can also highlight areas for operational improvement within the warehouse. Through observation and evaluation during drills, managers and supervisors can identify inefficiencies or bottlenecks that may hinder the smooth execution of emergency protocols.

For example, during a fire evacuation drill, it may become apparent that certain exit routes are congested or blocked. This information can then be used to reconfigure warehouse layout or implement better signage to ensure a more efficient evacuation process in case of a real emergency.

Additionally, safety drills provide an opportunity to assess the effectiveness of safety equipment and protocols. If, during a drill, an employee struggles to operate a fire extinguisher, it may indicate a need for additional training or potentially the need for more user-friendly equipment.

By continually evaluating and improving operations during safety drills, warehouses can enhance their overall efficiency and productivity, even in non-emergency situations.

Building Confidence and Preparedness

Lastly, safety drills help build confidence and preparedness among warehouse staff. By regularly practicing emergency procedures, employees gain a sense of familiarity and comfort with handling potentially stressful situations.

This sense of confidence is invaluable during a real emergency when individuals need to remain calm and focused. Knowing that they have gone through drills and received relevant training gives employees peace of mind, allowing them to respond swiftly and effectively when faced with a crisis.

In addition, safety drills create a sense of responsibility and accountability among employees. They understand the importance of following protocols and contributing to the overall safety culture of the warehouse.

HCO Innovations offers comprehensive warehouse safety evaluation services to help businesses assess their current safety protocol and identify areas for improvement. Contact us today to learn how our expertise can help enhance safety, productivity, and efficiency within your warehouse operations.

What are safety drills?

Safety drills are planned exercises or practice sessions that simulate emergency situations in order to train individuals on how to respond effectively.

Why are safety drills important for warehouse preparedness?

Safety drills are crucial for warehouse preparedness as they help in familiarizing workers with emergency procedures, identifying potential hazards, and ensuring a quick and coordinated response in case of an actual emergency.

What types of emergencies can safety drills prepare warehouse employees for?

Safety drills can prepare warehouse employees for a wide range of emergencies such as fires, chemical spills, natural disasters like earthquakes or floods, medical emergencies, and even security threats.

How often should safety drills be conducted in a warehouse?

Ideally, safety drills should be conducted at least once every six months to ensure that employees remain well-versed in emergency procedures and are prepared to respond effectively in different scenarios.

Who should participate in safety drills?

All warehouse employees, including both full-time and part-time staff, should participate in safety drills to ensure that everyone is aware of proper procedures and can contribute to a safe and coordinated response.

What are the benefits of safety drills for warehouse preparedness?

Some of the benefits of safety drills for warehouse preparedness include: improved employee awareness and response in emergencies, reduced injuries and potential loss of life, improved communication among employees and emergency response teams, and identification of areas for improvement in emergency procedures.

Are safety drills a legal requirement for warehouses?

While safety drill requirements may vary by jurisdiction, many countries have workplace safety regulations that mandate regular safety drills and emergency preparedness training for warehouse operations. It is important to consult local regulations to ensure compliance.

How can safety drills be made more effective?

To make safety drills more effective, it is important to set clear objectives, involve employees in the planning process, provide realistic scenarios, debrief after each drill to discuss strengths and areas for improvement, and regularly review and update emergency procedures based on lessons learned from drills.

The Importance of First Aid Training for Warehouse Employees

In today's fast-paced and demanding warehouse environments, the safety of employees should always be a top priority. While safety measures such as proper equipment maintenance and training on operating procedures are crucial, one aspect that is often overlooked is first aid training. Providing first aid training to warehouse employees is not only a legal requirement in many jurisdictions, but it is also a proactive step towards creating a secure and conducive working environment.

The Benefits of First Aid Training

First aid training equips employees with the knowledge and skills to respond effectively in emergency situations. In a warehouse setting, accidents can happen at any time, ranging from minor cuts and bruises to more serious injuries. Having employees trained in first aid can make a significant difference in the outcome of these incidents.

Here are some key benefits of providing first aid training to warehouse employees:

- Immediate response: Warehouse accidents and injuries can occur suddenly and without warning. When employees are trained in first aid, they can provide immediate care and potentially prevent the situation from worsening.

- Reduced recovery time: By administering timely first aid, the injured employee may experience faster recovery, minimizing downtime and the impact on productivity.

- Increased confidence: First aid training empowers employees by giving them the knowledge and skills to handle emergency situations. This increased confidence can translate into a safer and more efficient working environment.

- Improved teamwork: First aid training fosters a sense of teamwork and responsibility among employees. They learn to support one another and work together to ensure the well-being of their colleagues.

- Compliance with regulations: Many jurisdictions require employers to provide first aid resources and training for their employees. By implementing first aid training, warehouse operators can ensure compliance with these regulations.

It is important to note that while basic first aid training is beneficial, specialized training tailored to the unique needs of a warehouse environment can further enhance safety standards. Warehouse employees may encounter specific hazards such as falls from heights, forklift accidents, or exposure to hazardous substances. Specialized first aid training can focus on these scenarios, equipping employees with the skills to respond appropriately.

Choosing the Right First Aid Training Program

When selecting a first aid training program for warehouse employees, it is essential to consider the following factors:

- Reputation and expertise: Choose a training provider with a proven track record in delivering high-quality first aid training. Look for certifications and accreditations that validate their expertise.

- Customization options: Ensure that the training program can be tailored to address the specific hazards and challenges faced within your warehouse environment.

- Hands-on training: Practical exercises and simulations are crucial for employees to develop the necessary skills and confidence to handle real-life emergency situations.

- Continuing education: First aid techniques and practices evolve over time. Look for training programs that offer opportunities for ongoing education and skill development.

- Integration with existing safety procedures: The first aid training program should seamlessly integrate with your warehouse's existing safety protocols and emergency response plans.

At HCO Innovations, we understand the importance of first aid training in warehouse environments. As a leading management consulting firm specializing in warehouse optimization and forklift fleet management, we recognize the critical role that safety plays in operational efficiency. That's why we offer comprehensive services that include not only warehouse layout evaluation and turnkey solutions but also safety assessments and training programs tailored to the unique needs of warehouses.

Our skilled consultants, armed with advanced cost-tracking software and practical industry experience, help clients across various industries achieve significant cost reductions and enhance operational efficiency. With our collaborative "boots on the ground" approach, we work closely with your team to develop and implement effective first aid training programs that align with your safety objectives.

By partnering with HCO Innovations, you can ensure that your warehouse employees are equipped with the necessary skills to respond confidently and effectively in emergency situations. Contact us today at HCO Innovations to learn more about our comprehensive warehouse optimization services and how we can help enhance safety within your warehouse environment.