Chapter 6: Battery and Charging Systems

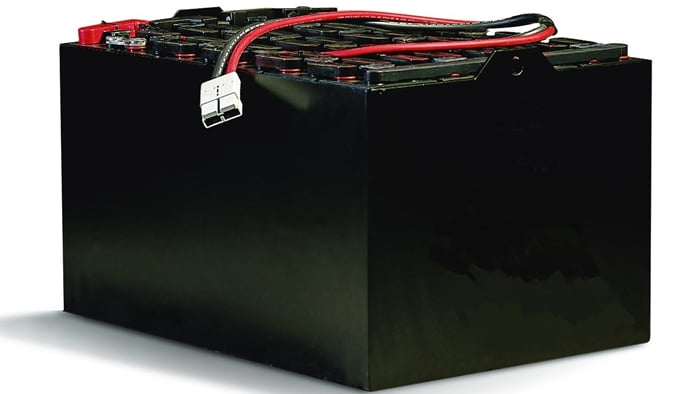

Lift truck batteries come in all shapes and sizes. A typical battery’s dimensions and weight can vary widely depending on the truck, but in the case of the 5,000 lb. electric sit-down counterbalanced lift truck, it’s approximately 40 inches wide by 32 inches high by 34 inches front-to-back, and it weighs around 3,200 lbs. A lift truck battery must continually provide power for vehicle systems (the three main system motors – drive, steering and load-lift), so its physical size and energy capacity must be large. Also, the heavy battery in a lift truck contributes a substantial amount of the truck’s counterweight.

How often a battery charge or change-out becomes necessary on an electric lift truck depends on how it is used. In a three-shift operation, a battery will definitely need to be changed out during the three shifts of work – physically removed and replaced by a fully-charged one. With the lead-acid battery technology present in today’s lift trucks, if the energy in the battery becomes depleted, it takes a long time to put the energy back into it correctly. In fact, it’s common in the material handling industry to refer to the “8-8-8 rule,” which means that it takes about 8 hours to deplete a battery working on the job, 8 hours to charge it back up and another 8 hours to allow the battery to sufficiently cool. New and emergent battery technologies are shortening the 8-8-8 rule times. For example, new high-frequency (HF) ‘fast-charging’ technology allows multi-shift operations to charge batteries partially during breaks in a shift, and then at lunch or at shift’s-end to fully charge it up in approximately an hour and a half. However, although this ‘fast-charging’ technology represents a significant improvement, there’s a limit in how far this technology can be taken. For example, ‘fast charging’ technology still requires a weekly “equalizing charge.”

Continue to Chapter 7…

Read The Full Series:

Chapter 1: The Concept of Total Cost of Ownership (TCO)

Chapter 2: AC Technology Compared to Internal Combustion

Chapter 3: Compressed Natural Gas (CNG)

Chapter 4: Trends in Materials Handling

Chapter 5: Voltage Levels Used in Electric Lift trucks Today

Chapter 6: Battery and Charging Systems

Chapter 7: Electric Braking and Energy Regeneration

Chapter 8: Emissions and Corporate Responsibility: A Major Problem for IC Lift Trucks

Conclusions & Final Recap

HCO Innovations is publishing this eight-part series as an in-depth comparative analysis and discussion on Compressed Natural Gas (CNG) Internal Combustion (IC) motors and Alternating Current (AC) Eletric lift truck engines, Comparison Analysis of CNG (IC) vs. AC Electric Lift Trucks, by Will Van Ness, VP of Fleet Management at HCO Innovations.

Comparison Analysis of CNG (IC) vs. AC Electric Lift Trucks (AC)

The materials handling industry continues to evolve at a rapid pace, particularly in the area of motive power propulsion. Tremendous technological advancements have been made over the past decade to directly address the rising cost of petrol (fossil fuels) along with stricter emission standards. Today’s MHE acquirers have more choices than ever when it comes to motive power propulsion and with the success seen amongst fleets utilizing alternative fuel sources such as lithium ion (LION) and Hydrogen Fuel Cell (HFC), the choices will most likely increase as time goes on. For the purpose of this discussion document, our focus will be on comparing AC Electric (AC) to Internal Combustion powered lift trucks (IC), specifically compressed natural gas (CNG).

What is the purpose of this chapter?

In this chapter, we will delve into the world of battery and charging systems. We will discuss the importance of a reliable battery and charging system in various applications, as well as the different components involved in these systems.

How does a battery store and release energy?

A battery stores chemical energy and converts it into electrical energy when needed. When a circuit is connected to the battery, a chemical reaction occurs inside the battery, causing electrons to move and create a flow of electricity. When the battery is being charged, the chemical reaction is reversed, and the battery stores energy for later use.

What factors should be considered when choosing a battery for a specific application?

Several factors need to be taken into account when selecting a battery for a specific application. These may include the required voltage and current, the battery's capacity to store energy, its size and weight, its lifespan, and its compatibility with the charging system. It is important to choose a battery that meets the specific requirements and demands of the application.

How does a charging system work?

A charging system is responsible for replenishing the energy stored in a battery. It typically consists of an alternator or generator, a voltage regulator, and a battery. The alternator or generator converts mechanical energy into electrical energy, which is then regulated by the voltage regulator to ensure the battery receives the correct charging voltage. The charging system keeps the battery charged and ready to supply power to the electrical components of a vehicle or system.

How can I extend the lifespan of my battery and charging system?

To extend the lifespan of your battery and charging system, it is crucial to properly maintain them. Regularly inspect the battery for signs of damage or corrosion, and clean the terminals if necessary. Keep the battery and charging system components clean and free from dirt and debris. Avoid overcharging or deep discharging the battery, as it can lead to premature failure. It is also advisable to follow the manufacturer's guidelines for maintenance and ensure proper installation and wiring.

What are the common signs of a failing battery or charging system?

Some common signs of a failing battery or charging system include a weak or dead battery, difficulty starting the vehicle or system, dim or flickering lights, a burning smell, or a warning light on the dashboard indicating a charging system malfunction. If you notice any of these signs, it is important to have your battery and charging system inspected and repaired by a qualified professional.

Electric Vehicle (EV) Charging Infrastructure: Current Challenges and Future Developments

As the world becomes increasingly aware of the detrimental effects of fossil fuels on the environment, there has been a significant shift towards the adoption of electric vehicles (EVs). With this surge in EV usage, the development of a robust and efficient EV charging infrastructure has become a top priority. In this article, we will delve into the current challenges faced by the EV charging infrastructure and explore the future developments that are set to revolutionize this industry.

Challenges in the Current EV Charging Infrastructure

While the demand for EVs continues to rise, the existing charging infrastructure faces several challenges that need to be addressed:

- Limited Charging Stations: One of the primary challenges is the limited number of charging stations available. This scarcity can lead to long waiting times and inconvenience for EV owners.

- Slow Charging Speeds: Traditional charging methods can be time-consuming, with some systems taking several hours for a full charge. This slow charging speed hampers the convenience and practicality of EV usage.

- Variability in Charging Standards: Different EV manufacturers have developed their own charging standards, resulting in a lack of uniformity in charging infrastructure. This inconsistency can make it difficult for EV owners to find compatible charging stations.

- Range Anxiety: Range anxiety refers to the fear of running out of battery power while driving. The limited range of many EVs, coupled with insufficient charging infrastructure, can heighten this concern among potential EV buyers.

Addressing these challenges is crucial for the widespread adoption of EVs and the establishment of an efficient charging infrastructure.

Future Developments in EV Charging Infrastructure

The future of EV charging infrastructure looks promising, with significant developments on the horizon. Here are some advancements that will shape the industry:

- Increased Charging Station Availability: To meet the growing demand for EV charging, more charging stations will be deployed in strategic locations. This expansion aims to eliminate long waiting times and make charging easily accessible.

- Rapid Charging Technologies: The development of rapid charging technologies will significantly reduce charging times. New systems like Level 3 DC fast charging can provide an 80% charge in just 30 minutes, making EV charging comparable to refueling a conventional vehicle.

- Standardized Charging Infrastructure: Efforts are underway to establish standardized charging protocols that will ensure compatibility across different EV models. This standardization will simplify the charging process and make it more convenient for EV owners.

- Wireless Charging: Wireless charging is poised to be a game-changer in the EV charging infrastructure. This technology allows EVs to charge through induction, eliminating the need for physical connections. With wireless charging, EVs could be charged automatically while parked or even while driving, making the charging process seamless and hassle-free.

- Integration with Renewable Energy Sources: The increased focus on renewable energy sources presents an opportunity to integrate EV charging infrastructure with solar or wind power. This combination will not only reduce dependence on the electrical grid but also promote sustainable energy usage.

With these future developments, the EV charging infrastructure is set to undergo a transformation, overcoming existing challenges and paving the way for widespread EV adoption.

As a leading management consulting firm specializing in warehouse optimization and forklift fleet management, HCO Innovations understands the importance of staying on top of industry advancements. Just as the EV charging infrastructure is evolving, so are warehouse operations. HCO Innovations leverages advanced cost-tracking software and a collaborative approach to help clients optimize their warehouse operations, achieve cost reductions, and improve efficiency. With their turnkey maintenance solutions and safety assessments, HCO Innovations is a trusted partner for companies across industries seeking to enhance their material handling processes.

Conclusion

The future of EV charging infrastructure is promising and will witness remarkable advancements. Overcoming current challenges and embracing innovative technologies will pave the way for a seamless and efficient charging experience for EV owners. As the industry progresses, consulting firms like HCO Innovations will be at the forefront, providing guidance and expertise to businesses in their quest for operational efficiency and cost reduction. The journey towards a sustainable and electrified transportation future is well underway.