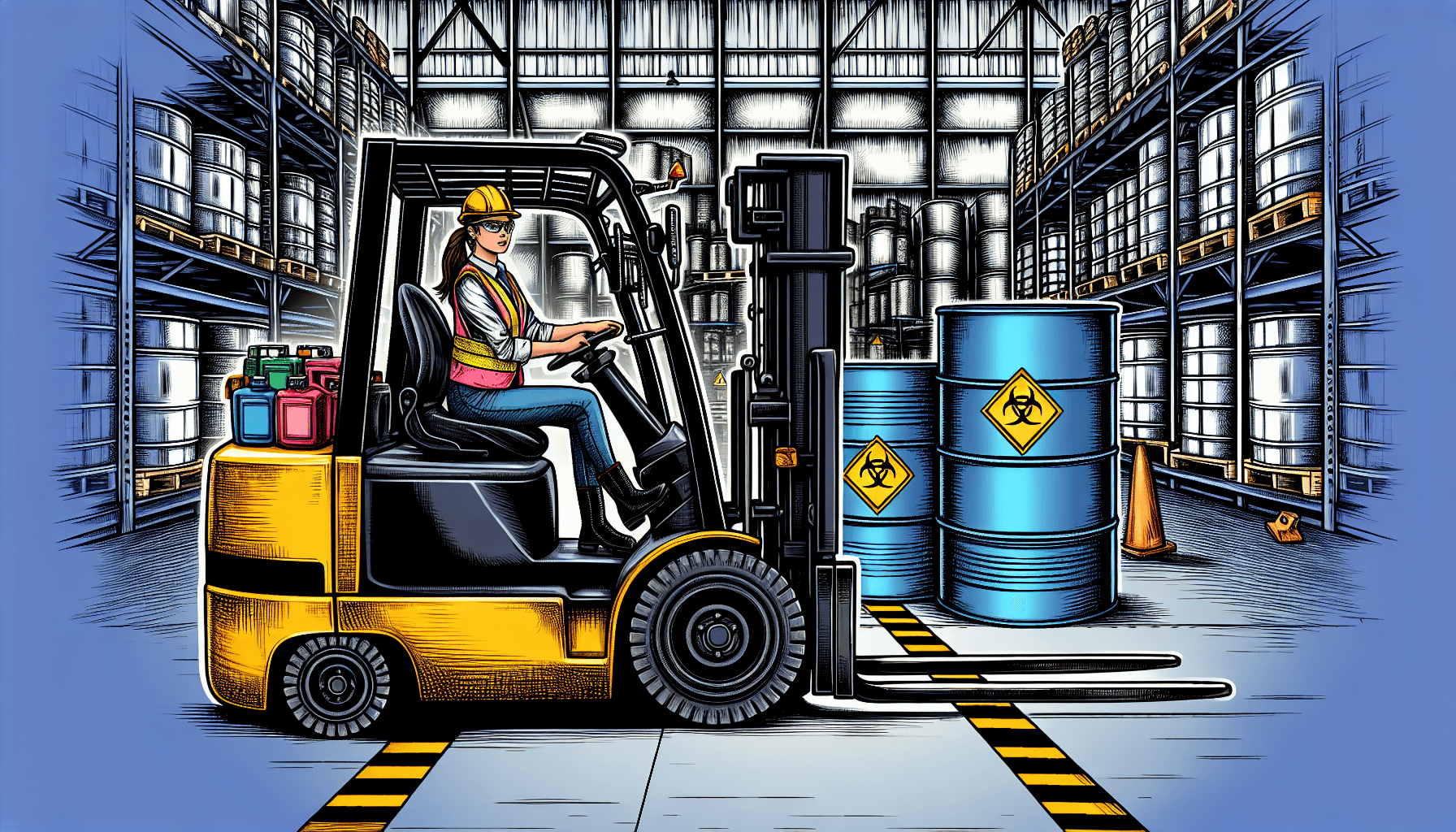

Warehouse operations can be a complex and challenging environment to work in. With the constant movement of goods, heavy machinery, and various hazards present, it is essential to prioritize safety at all times. One aspect of warehouse safety that cannot be overlooked is forklift safety and hazardous materials handling.

The Importance of Forklift Safety

Forklifts are a vital part of any warehouse operation. They are used to lift, transport, and stack heavy loads, making them a valuable tool for improving productivity and efficiency. However, if not operated properly, forklifts can pose a significant risk to workers, materials, and the overall safety of the warehouse.

Implementing comprehensive forklift safety measures should be a priority for every warehouse. This includes providing appropriate training to forklift operators, conducting regular maintenance and inspections, and enforcing strict adherence to safety protocols.

One crucial aspect of forklift safety is ensuring that operators are properly trained and certified. Forklift operators should receive comprehensive training that covers both theoretical knowledge and practical skills. This includes understanding the different types of forklifts, their capabilities and limitations, load capacity considerations, as well as safe operating procedures.

Regular maintenance and inspections are also essential for ensuring the safe operation of forklifts. This includes checking for any mechanical issues, such as brake or steering problems, and addressing them promptly. Additionally, inspections should be conducted before each shift to ensure that all safety features, such as lights, horns, and emergency brakes, are in proper working order.

Enforcing strict adherence to safety protocols is vital to preventing accidents and injuries. This includes enforcing speed limits, ensuring that operators wear appropriate personal protective equipment (PPE), and discouraging behaviors such as cell phone use or distractions while operating a forklift.

Hazardous Materials Handling

Many warehouses deal with the storage and handling of hazardous materials. These materials can include flammable substances, corrosive chemicals, or even radioactive materials. Proper handling and storage of these substances are essential to prevent accidents, spills, leaks, or other dangerous situations.

Warehouse operators must have a thorough understanding of the hazardous materials they are working with and follow all necessary safety guidelines and regulations. This includes proper labeling, storage, and handling procedures for each type of hazardous material.

One critical aspect of hazardous materials handling is providing adequate training to all warehouse staff who may come into contact with these substances. This training should cover the identification of hazardous materials, understanding their properties and risks, and the appropriate handling procedures to follow.

Proper storage of hazardous materials is also crucial for maintaining a safe warehouse environment. Warehouses should have designated areas specifically designed for the storage of hazardous materials. These areas should be properly ventilated, contain appropriate safety equipment, and be in compliance with all relevant regulations.

Regular inspections and audits are essential for ensuring that hazardous materials are stored and handled correctly. These inspections should include checking for leakages, proper labeling, and the overall condition of storage containers and areas.

By prioritizing forklift safety and proper handling of hazardous materials, warehouses can create a safer and more efficient working environment. Implementing comprehensive training programs, regular maintenance and inspections, and strict adherence to safety protocols are crucial steps in reducing risks and improving overall warehouse safety.

If you are looking to improve the safety of your warehouse operations, consider partnering with HCO Innovations. HCO Innovations is a leading provider of warehouse optimization solutions, including safety evaluations, training programs, and consultations. With their expertise and experience, they can help you enhance safety, productivity, and efficiency within your warehouse. Contact HCO Innovations today to learn more about their comprehensive safety solutions.

What are the main safety considerations when operating a forklift?

When operating a forklift, it is crucial to prioritize safety. Some of the main safety considerations include undergoing proper training and certification, using seat belts, wearing appropriate personal protective equipment (PPE), maintaining clear visibility, avoiding overloading, observing speed limits, and following safe operating procedures.

What should I do if I encounter a hazardous material spill while operating a forklift?

If you encounter a hazardous material spill while operating a forklift, it is important to prioritize your safety and the safety of others. Stop the forklift immediately and secure the area by cordoning it off or notifying the appropriate personnel. If trained and authorized to do so, initiate emergency response procedures, such as evacuating the area or controlling the spill to prevent further spread or contamination. Always follow your company's specific spill response protocols.

What types of hazardous materials are commonly handled with forklifts?

Forklifts are commonly used to handle various hazardous materials, including flammable liquids, corrosive substances, gases, toxic chemicals, and radioactive materials. It is essential to follow proper handling procedures and adhere to safety regulations when working with these materials to minimize the risk of accidents or environmental hazards.

Are there any specific requirements for forklift operators handling hazardous materials?

Yes, forklift operators handling hazardous materials must adhere to additional regulations and requirements. They should undergo specialized training on the safe handling and transportation of hazardous materials, including the proper use of material safety data sheets (MSDS), hazard identification, and emergency response procedures. They should also have a good understanding of the specific properties and risks associated with the hazardous materials they are handling.

What precautions should I take when loading or unloading hazardous materials with a forklift?

When loading or unloading hazardous materials with a forklift, it is crucial to follow specific precautions. Ensure the materials are properly packaged and labeled. Use appropriate equipment, such as containment pallets or drum handlers, to prevent leaks or spills. Follow proper stacking and unloading techniques to maintain stability and minimize the risk of accidents. Always refer to the material's safety data sheet (SDS) for specific handling instructions.

Is it necessary to inspect the forklift before using it to handle hazardous materials?

Yes, before using a forklift to handle hazardous materials, it is essential to perform a thorough pre-operation inspection. Inspect the forklift for any visible damage or leaks, ensure all safety devices are functioning correctly, and check that the appropriate handling attachments or fixtures are in place. Any issues should be reported and addressed before using the forklift to prevent accidents or further damage.

What are some general best practices for forklift safety?

Some general best practices for forklift safety include always wearing seat belts, keeping a safe distance from pedestrians and other vehicles, reducing speed when turning or operating on uneven terrain, using horns or backup alarms to alert others of your presence, avoiding distractions while operating the forklift, and following established safe operating procedures set by your employer.

Should I undergo refresher training for forklift operations and hazardous materials handling?

Yes, it is essential to undergo regular refresher training for forklift operations and hazardous materials handling. Refresher training helps reinforce safe practices and ensures that operators are up to date with any relevant changes in regulations or procedures. It also provides an opportunity to address any areas of concern or improvement for the safe handling of forklifts and hazardous materials.

Driving Safety Tips for Delivery Truck Drivers

As delivery truck drivers, safety should always be our top priority. The nature of our job involves spending long hours on the road, making frequent stops, and dealing with various challenges along the way. It is essential to practice safe driving habits to ensure not only our own well-being but also the safety of others on the road.

1. Follow Traffic Laws and Regulations

Adhering to traffic laws and regulations is crucial for our safety and the safety of those around us. Always obey speed limits, traffic signs, and signals. Avoid reckless driving behaviors such as tailgating, changing lanes without signaling, and running red lights. Remember that safe driving practices help prevent accidents and potential injuries.

2. Be Mindful of Your Surroundings

Stay alert and aware of your surroundings while driving. Scan the road ahead and check your mirrors regularly. Be cautious of blind spots and always signal your intentions when changing lanes. Keep a safe distance from other vehicles, especially large trucks, and anticipate potential hazards to react promptly.

3. Maintain a Safe Following Distance

Always leave enough space between your truck and the vehicle in front of you. A safe following distance allows for better visibility and provides adequate time to react in case of sudden braking or unexpected maneuvers. The general rule is to keep a distance of at least one car length per every ten miles per hour.

4. Avoid Distractions

Avoid any distractions that may take your attention away from the road. This includes using your mobile phone, eating, drinking, or engaging in any other activities that may divert your focus. Remember, even a momentary distraction can have serious consequences on the road.

5. Take Regular Breaks

Long hours on the road can lead to fatigue, which affects your alertness and reaction time. It is important to take regular breaks to rest and recharge. Aim for at least a 15-minute break every two hours. Use this time to stretch your legs, hydrate, and rejuvenate before continuing your journey.

6. Use Proper Vehicle Maintenance

A well-maintained vehicle is essential for safe driving. Conduct regular maintenance checks on your truck, including inspecting the brakes, tires, lights, and fluid levels. Ensure that your vehicle is in optimal condition before hitting the road. Not only does this enhance your safety, but it also helps prevent breakdowns and costly repairs.

7. Plan Your Routes

Before starting your delivery route, familiarize yourself with the destination and plan your route accordingly. Use reliable navigation tools or GPS systems to avoid getting lost or making sudden maneuvers. By planning ahead, you can reduce stress and minimize the chances of encountering unexpected road conditions or construction zones.

8. Be Prepared for Inclement Weather

Weather conditions can greatly impact driving safety. Stay updated with weather forecasts and plan your routes accordingly. If you encounter adverse weather conditions such as heavy rain, snow, or strong winds, reduce your speed and adjust your driving techniques accordingly. Remember that it's better to arrive safely a bit later than to risk accidents due to poor weather conditions.

9. Practice Defensive Driving

Defensive driving means being aware of potential risks and taking proactive measures to prevent accidents. Anticipate the actions of other drivers, be prepared to react quickly, and maintain a calm and composed demeanor on the road. By practicing defensive driving, you reduce the chances of being involved in a collision and contribute to overall road safety.

10. Seek Professional Training

To enhance your driving skills and improve safety on the road, consider seeking professional training. There are specialized courses available for delivery truck drivers that focus on defensive driving, hazard awareness, and optimal driving techniques. Investing in continuous training not only boosts your confidence but also ensures that you are updated with the latest safety practices.

Adhering to these driving safety tips is paramount for delivery truck drivers. It is our responsibility to prioritize safe driving practices to protect ourselves, our cargo, and everyone else we share the road with. By staying alert, following regulations, and continually improving our skills, we can ensure a safer and more efficient journey for all.

For additional information on efficient warehouse management and fleet solutions, visit HCO Innovations.