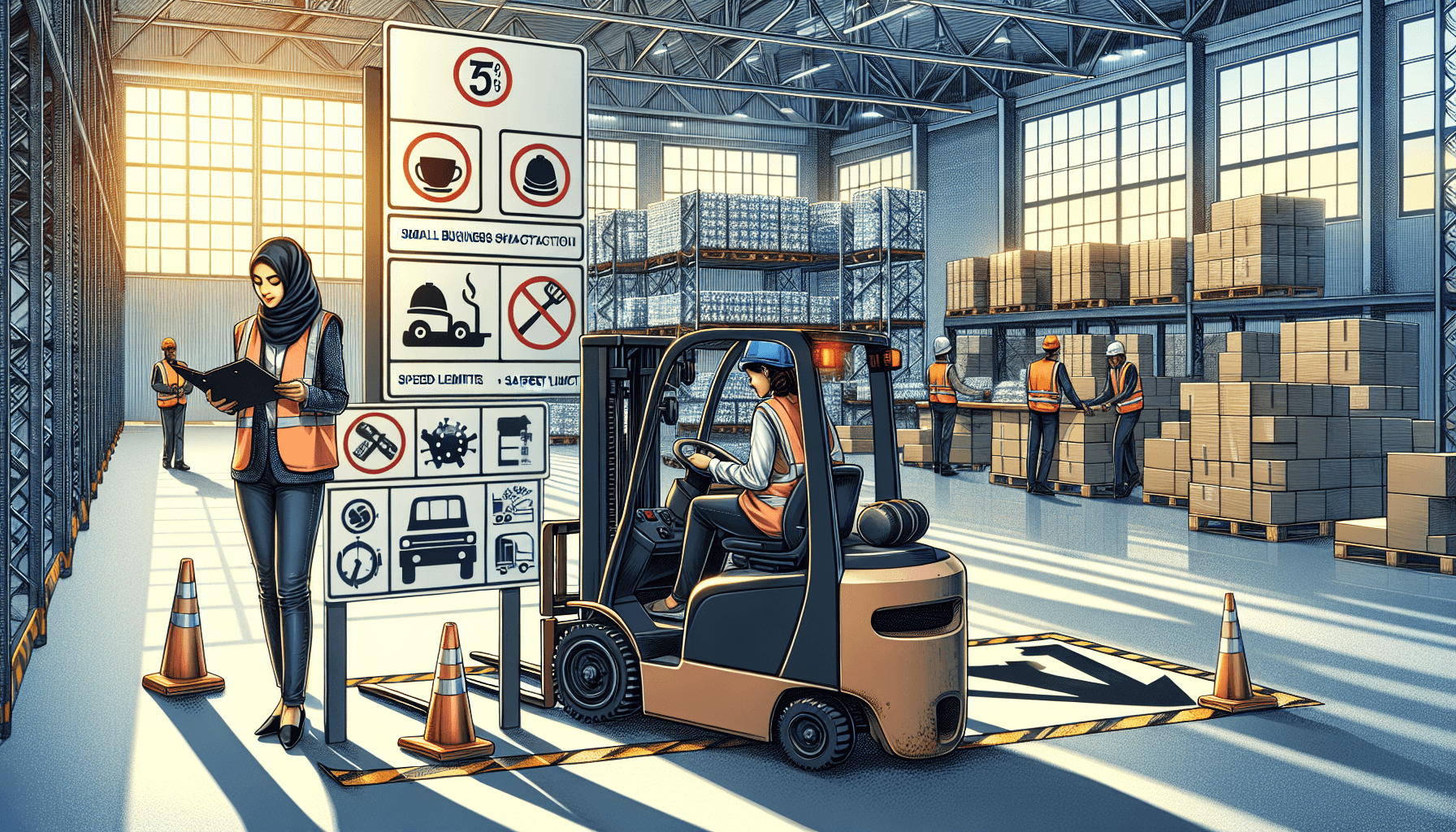

Maintaining a safe working environment is crucial for any business, especially in industries like warehousing and distribution where there are various hazards. Forklifts, in particular, are a common sight in warehouses and play a vital role in material handling. However, without proper safety measures and training, forklift operations can lead to serious accidents and injuries. In this article, we will discuss the importance of forklift safety for small businesses and provide some useful tips to ensure a safe work environment.

The Importance of Forklift Safety

Forklift accidents can result in severe injuries and even fatalities. According to the Occupational Safety and Health Administration (OSHA), approximately 100,000 forklift accidents occur each year in the United States, with about 85 forklift-related fatalities. These statistics highlight the importance of prioritizing forklift safety in your warehouse operations.

Implementing proper forklift safety measures not only helps prevent accidents but also ensures the smooth and efficient functioning of your warehouse. By prioritizing forklift safety, you can minimize equipment damage, reduce downtime for repairs, and ultimately increase productivity and profitability.

Training and Certification

One of the most critical aspects of forklift safety is providing proper training to your forklift operators. Operating a forklift requires specific skills and knowledge, and employees should undergo thorough training before they are allowed to operate the machinery.

Small businesses should invest in forklift operator training programs that cover essential topics such as forklift operation techniques, load handling, safety procedures, and emergency protocols. By providing comprehensive training, you empower your employees to operate forklifts safely and responsibly.

Additionally, it is important to ensure that your forklift operators are certified. Certification programs assess an operator’s skills and knowledge through written exams and practical evaluations. Certified operators are more likely to adhere to safety protocols and demonstrate competence in operating forklifts.

To further enhance forklift safety, ongoing training and refresher courses should be provided to ensure that your operators are updated on the latest safety standards and practices.

Warehouse Layout and Design

The layout and design of your warehouse can greatly impact forklift safety. A well-designed warehouse layout takes into account factors such as traffic flow, aisle width, signage, and designated pedestrian walkways.

Clear markings and signage should be used to indicate forklift zones, pedestrian-only areas, and restricted areas. Proper lighting is also essential to ensure visibility, especially in areas where forklifts operate.

In addition, maintaining clear and unobstructed aisles is crucial for safe forklift operation. Avoid cluttering aisles with excess inventory or obstacles that can impede the movement of forklifts.

Maintenance and Inspections

Regular maintenance and inspections of forklifts are essential to ensure their safe operation. Small businesses should establish a routine maintenance schedule and conduct thorough inspections to identify and address any potential issues before they become major safety hazards.

Documented pre-shift inspections should be conducted by forklift operators to check for any visible damages, faulty parts, or malfunctioning systems. Any identified issues should be reported immediately and addressed by trained maintenance personnel.

Regular maintenance tasks may include checking fluid levels, inspecting brakes, hydraulics, and tires, and ensuring that all safety features like seat belts and horns are functioning properly. By keeping forklifts in good working condition, you reduce the risk of accidents caused by mechanical failures.

Implement Safety Policies and Procedures

Establishing and enforcing safety policies and procedures is an essential part of ensuring forklift safety. Clear guidelines should be in place for operating forklifts, including speed limits, safe maneuvering, and proper use of forks and attachments.

These policies should also outline procedures for reporting accidents, near misses, and safety concerns. Encouraging a culture of reporting and feedback is crucial to continually improve safety in your warehouse operations.

Regular safety meetings and toolbox talks can help reinforce safety practices and provide an opportunity for employees to share their experiences and suggestions for improving forklift safety.

Invest in Warehouse Safety Solutions

To enhance forklift safety, small businesses can benefit from investing in warehouse safety solutions offered by companies like HCO Innovations. These solutions include advanced technologies and systems that help optimize warehouse operations while ensuring safety and efficiency.

HCO Innovations provides warehouse optimization solutions that are designed to enhance safety, productivity, efficiency, and cost-effectiveness within warehouse operations. Their comprehensive services include warehouse safety evaluations, training programs, and advanced safety solutions tailored to the needs of small businesses. To learn more about their warehouse safety evaluation services, you can visit their website here.

By implementing the tips mentioned above and investing in warehouse safety solutions, small businesses can create a safe working environment and protect their employees from forklift accidents. Prioritizing forklift safety not only reduces the risk of injuries and fatalities but also drives productivity and ensures the smooth functioning of warehouse operations.

Remember, forklift safety is a shared responsibility, and everyone in your organization should be committed to following safety protocols and best practices. By working together, you can create a culture of safety and minimize the risk of forklift accidents in your small business.

What is the importance of forklift safety for small businesses?

Forklift safety is crucial for small businesses to prevent accidents, injuries, and property damage. Implementing proper forklift safety measures ensures the protection of employees, promotes a safe work environment, reduces liabilities, and improves overall productivity.

What are the primary causes of forklift accidents?

Common causes of forklift accidents include inadequate training, speeding, improper loading, unstable loads, improper turning, lack of visibility, and hazardous working conditions. By addressing these factors and implementing proper safety procedures, businesses can significantly reduce the risk of accidents.

What are the essential forklift safety tips?

Some key forklift safety tips include conducting thorough training for operators, performing regular equipment inspections, maintaining clear visibility by removing obstacles, using seat belts, obeying speed limits, keeping a safe distance from pedestrians and other vehicles, and following proper loading and unloading procedures.

How can employers ensure proper forklift operator training?

Employers should provide comprehensive training programs for forklift operators. The training should cover topics such as equipment operation, load handling, maneuvering, safety procedures, and emergency protocols. Employers should also offer refresher training sessions periodically to reinforce safe practices.

What are some best practices for forklift maintenance?

Best practices for forklift maintenance include regularly inspecting the equipment for any signs of wear or damage, promptly addressing any issues or malfunctions, keeping up with routine maintenance tasks such as oil changes and tire checks, and following the manufacturer's recommended maintenance schedule.

What safety measures can be implemented to prevent forklift tip-overs?

To prevent forklift tip-overs, businesses should ensure that operators are trained on proper load handling techniques, avoid overloading the forklift beyond its rated capacity, maintain proper balance by keeping the load centered and as low as possible, and avoid making sharp turns or sudden movements that could destabilize the equipment.

Are there any specific safety guidelines for forklift pedestrians?

Yes, pedestrians should always be aware of their surroundings in areas where forklifts are in operation. They should use designated walkways, be cautious when approaching blind corners or intersections, make eye contact with forklift operators before crossing paths, and report any unsafe or hazardous conditions to the appropriate supervisor.

What should be done in case of a forklift accident or injury?

In case of a forklift accident or injury, the immediate priority is to ensure the safety and well-being of all individuals involved. First, contact emergency services if necessary. Then, report the incident to a supervisor or safety officer, gather any necessary information or evidence, and cooperate fully with any investigations or inquiries that follow.

How can small businesses promote a culture of forklift safety?

Small businesses can promote a culture of forklift safety by prioritizing regular training and refresher courses, enforcing safety protocols and procedures consistently, incentivizing and rewarding safe practices, conducting regular safety audits, and fostering open communication between management, supervisors, and employees regarding safety concerns.

Where can I find additional resources on forklift safety for small businesses?

There are many reputable resources available online and through government agencies that provide valuable information on forklift safety. Some recommended sources include Occupational Safety and Health Administration (OSHA), Forklift Safety Training Services, and the National Safety Council.

Small businesses face unique challenges when it comes to warehouse operations. Limited space, budget constraints, and a need for optimal efficiency all come into play. That's why effective warehouse layout design is crucial for small businesses looking to maximize their operations and streamline their processes.

The Importance of Warehouse Layout Design

The layout of a warehouse has a direct impact on its overall productivity and efficiency. A well-designed layout ensures that goods can be stored, accessed, and moved with ease, minimizing the time and effort required for various tasks. This translates to better inventory management, faster order fulfillment, and reduced operational costs.

For small businesses, these benefits are especially critical. With limited resources, small warehouses must make the most out of every square foot of space and optimize their workflows to stay competitive. This is where HCO Innovations comes in - a leading management consulting firm that specializes in warehouse optimization for small businesses.

HCO Innovations understands the unique challenges faced by small businesses and offers tailored solutions to help them optimize their warehouse layouts and improve their overall operations.

Key Considerations for Warehouse Layout Design

When designing a warehouse layout, small businesses need to take several factors into account. Here are some key considerations:

- 1. Space Utilization: Small businesses need to make the most of their available space. This involves efficient use of vertical space through racking systems, as well as well-organized storage areas and clear aisles for ease of movement.

- 2. Process Flow: Analyzing the flow of materials and products is crucial for designing an effective layout. It's important to consider the sequence of operations, the location of receiving and shipping areas, and the placement of different workstations.

- 3. Accessibility: Easy access to inventory is essential for timely order fulfillment. Warehouse layout design should prioritize the accessibility of goods, with frequently picked items located closest to shipping areas.

- 4. Safety: Ensuring a safe working environment is a top priority in warehouse operations. Layout design should include safety measures such as designated walkways, proper lighting, and clear signage.

- 5. Scalability: Small businesses need a layout that allows for growth and expansion. Flexibility should be built into the design to accommodate changing storage needs and business expansion.

The HCO Innovations Advantage

When it comes to designing warehouse layouts for small businesses, HCO Innovations offers a unique advantage. With years of experience and a deep understanding of the challenges faced by small warehouses, they provide comprehensive solutions that are tailored to the specific needs of each client.

HCO Innovations leverages advanced cost-tracking software and takes a collaborative "boots on the ground" approach to ensure the best results. They work closely with clients to evaluate their current operations, identify areas for improvement, and design customized layouts that optimize space utilization, process flow, and safety.

By partnering with HCO Innovations, small businesses can expect the following benefits:

- Significant cost reductions through optimized warehouse layouts and streamlined workflows.

- Improved operational efficiency, leading to faster order fulfillment and increased customer satisfaction.

- Better inventory management, minimizing stockouts and reducing carrying costs.

- Enhanced safety measures, reducing the risk of workplace accidents and injuries.

- Scalable solutions that can adapt to future growth and changing business needs.

By investing in professional warehouse layout design services, small businesses can overcome the challenges they face and position themselves for success. With HCO Innovations as their trusted partner, they can achieve significant cost reductions, operational efficiency, and ultimately, a competitive edge in their industry.

>

For more information on how HCO Innovations can help your small business optimize its warehouse layout, visit their website or contact their team of experts.