Warehouse Fleet Management That Delivers Results

Streamline warehouse operations, reduce maintenance costs, and maintain full visibility with a powerful, integrated warehouse fleet management platform.Try It Free for 30 Days!

Our Warehouse Fleet Management Portal is your all-in-one solution for centralized fleet data, real-time insights, and cost-efficiency. Reduce manual workload, improve fleet visibility, and make smarter decisions across your warehouse network.

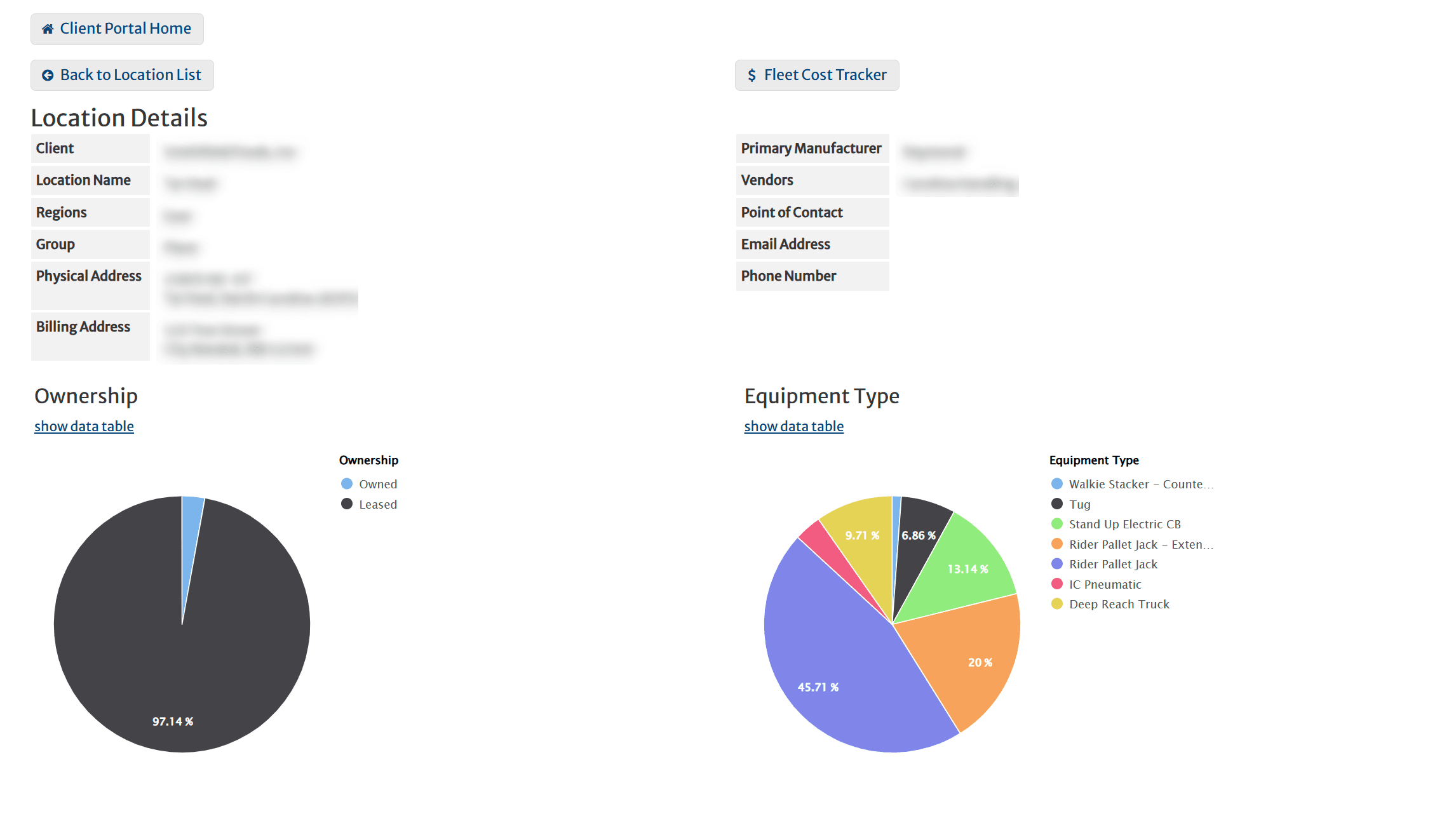

Comprehensive Warehouse Asset Management Portal

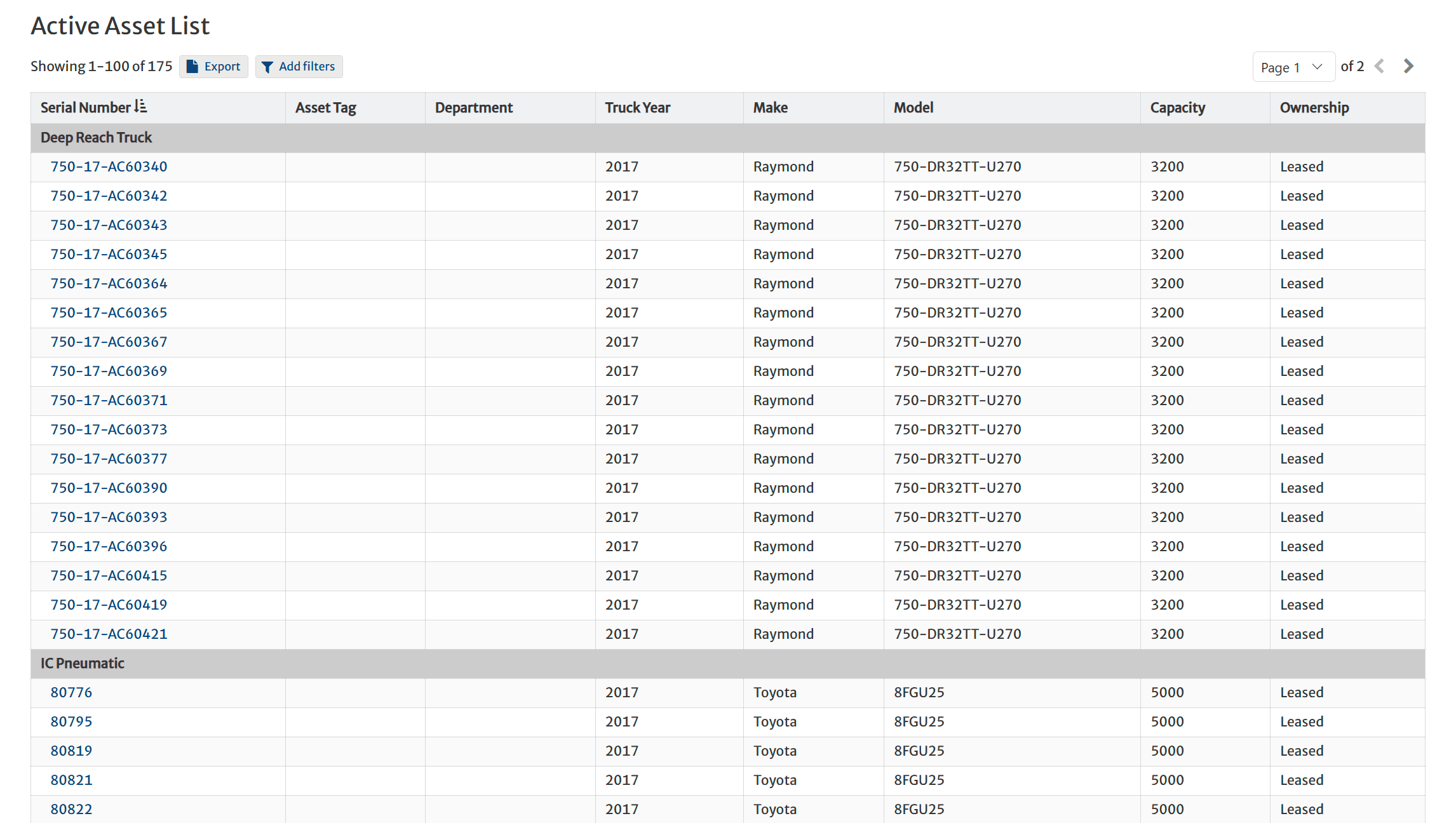

Access and manage your entire fleet from anywhere. Our cloud-based system supports multi-site operations and stores all vehicle data in one place, eliminating spreadsheets and outdated tools.

Real-Time Warehouse Fleet Tracking System

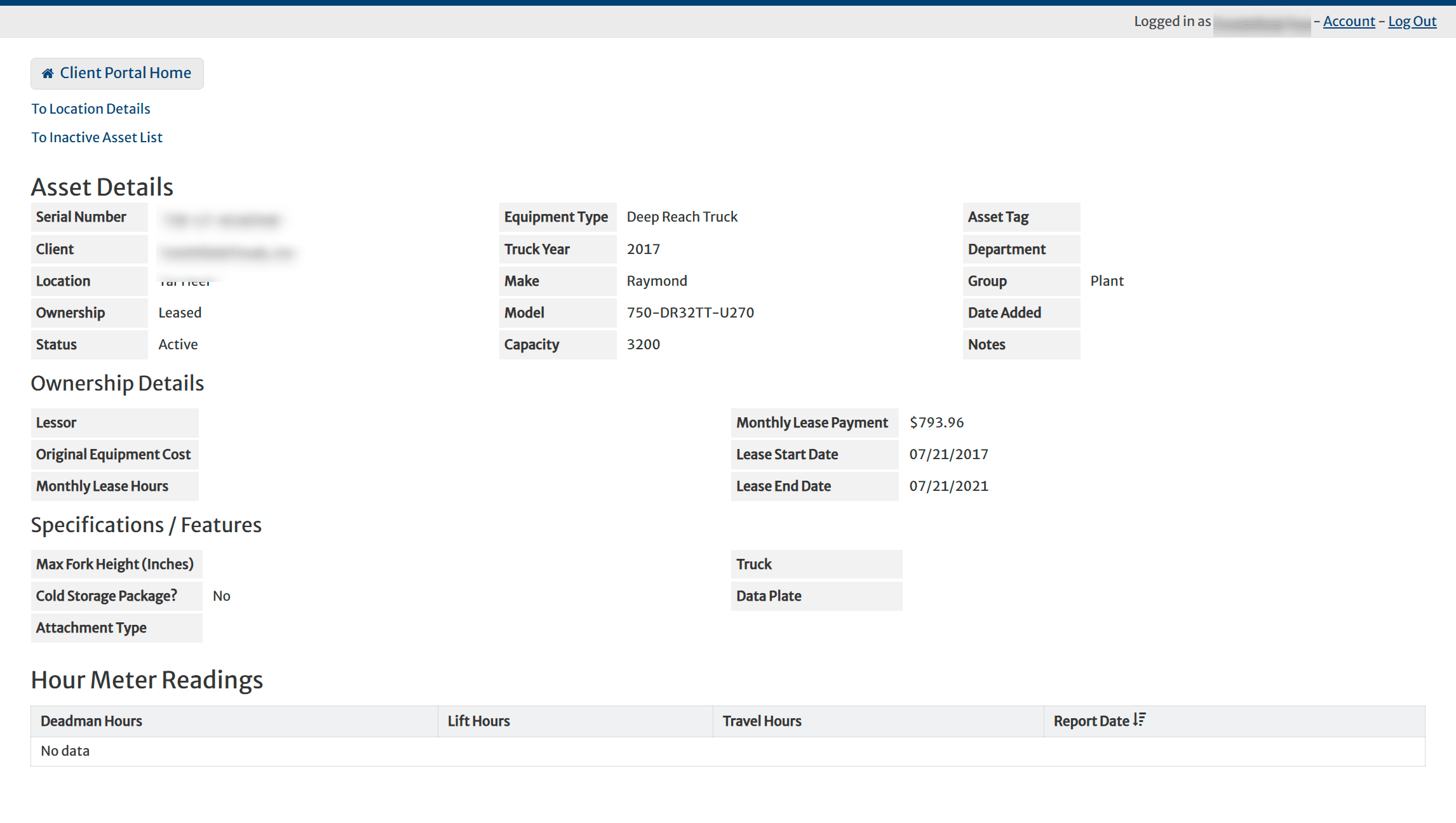

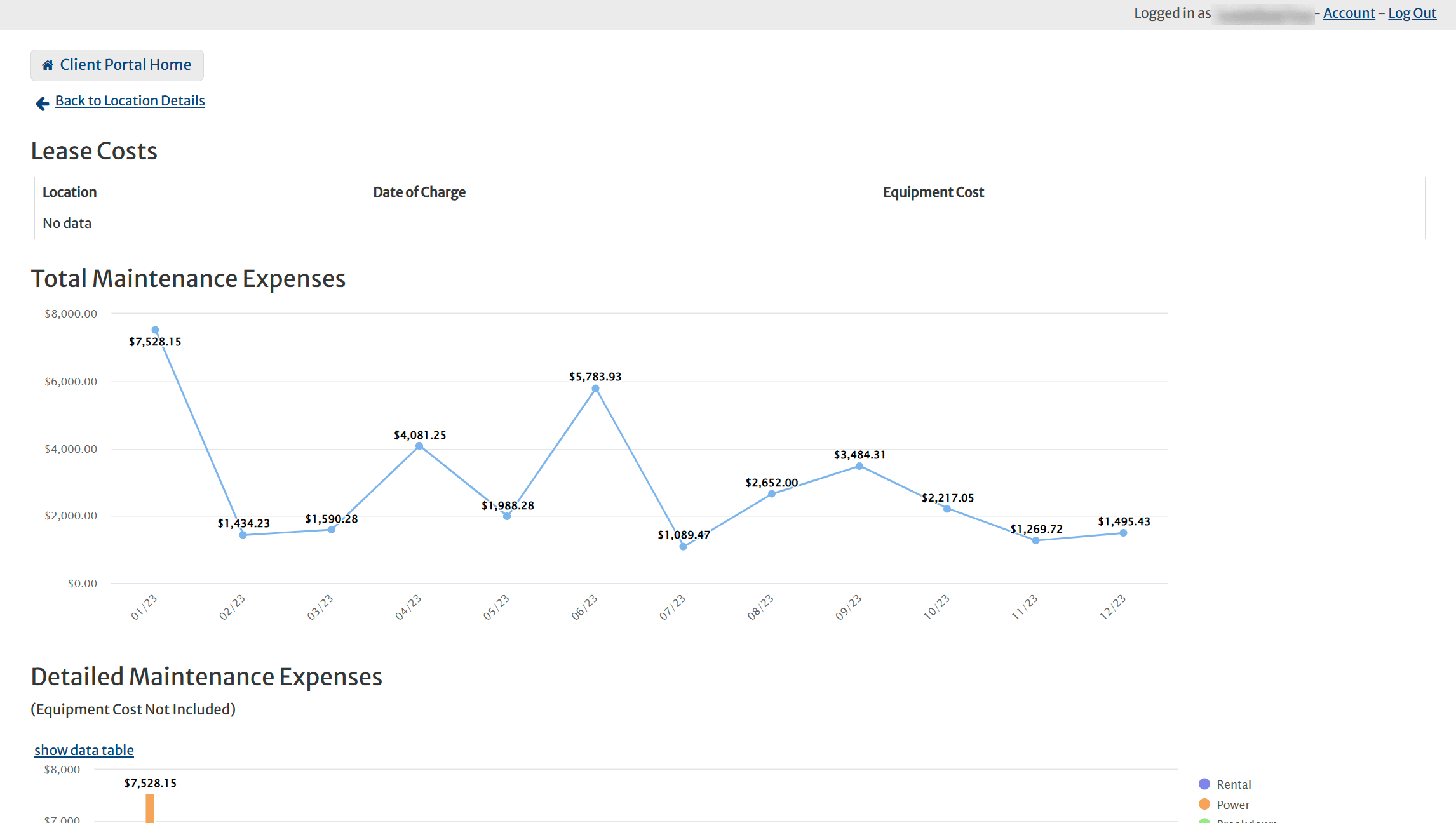

Gain live visibility into your warehouse vehicles. Instantly view performance, maintenance schedules, high-cost units, and lease expirations across all facilities.

Warehouse Vehicle Maintenance Scheduling Platform

Stay on top of service needs with proactive alerts and automated scheduling. Reduce downtime and extend equipment life.

Lease Management

Track upcoming lease expirations and manage terms across your fleet to avoid surprises and improve contract outcomes.

Optimize Warehouse Vehicle Operations

Right-size your fleet using real-time data and usage trends. Identify underutilized assets and optimize equipment types for productivity and cost savings.

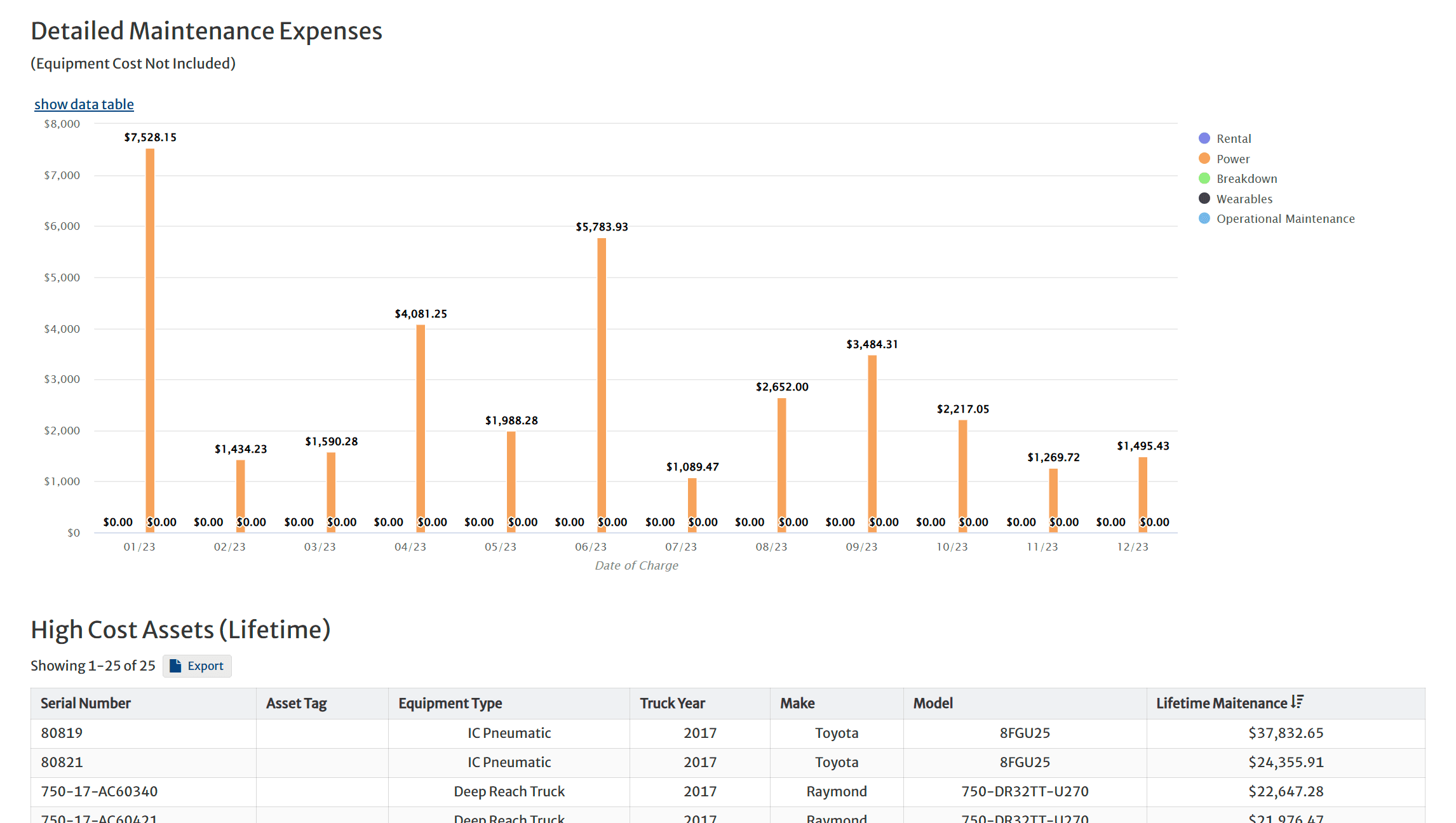

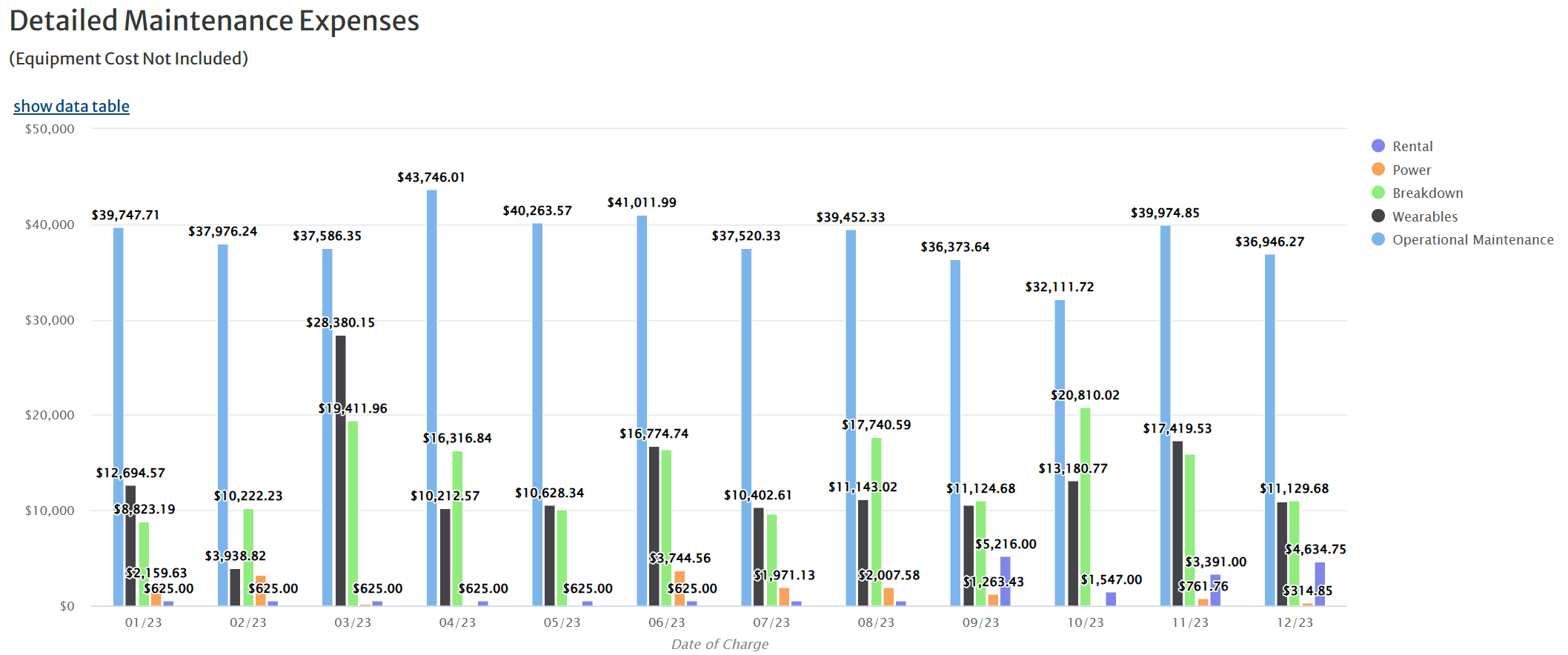

Warehouse Fleet Performance Analytics Software

Drill into detailed analytics for insights into cost drivers, operator behavior, and asset utilization. Generate reports to support smarter operational decisions.

How It Works

Simple Setup, Real-Time Insights, and Tangible Results in Just a Few Steps

Step 1. Sign Up

Register for your 30-day free trial with basic information—no payment required. Get instant access to explore our warehouse fleet management software solutions.

Step 2. Upload Fleet Data

Input details about your warehouse equipment: make, model, year, maintenance history, lease terms. Our team provides templates and support to simplify the process.

Step 3. Get Real-Time Insights

Start tracking your fleet with real-time dashboards. Monitor costs, spot inefficiencies, and receive alerts. Use customizable views to stay informed and take action fast.

Step 4. Optimize and Grow

Use performance data to reduce fleet size, extend equipment life, and lower operational costs. Build custom reports that align with your business goals.

Why Choose Our Warehouse Forklift Fleet Management Solutions?

Our portal is built for warehouse operations. From fleet tracking to cost control, our integrated warehouse fleet operations management system improves efficiency and saves you time and money.

"This portal has saved us hours each week. We've streamlined maintenance tracking and improved our lease management. We’ve already reduced our costs by 15% in just six months."

– Warehouse Operations Manager

Pick a Plan that Works for Your Business Model

Free Trial

- Centralized Fleet Data Management

- Real-time Visibility

- Maintenance Cost Tracking

- Lease Management

- Site to Site Comparison

- Online Reviews with HCO Fleet Expert

- Fleet Optimization

- MHE Quote Comparison Tool

- Discounted Workplace Safety Assessment

- Annual Workplace Safety Assessments

Premium

- Centralized Fleet Data Management

- Real-time Visibility

- Maintenance Cost Tracking

- Lease Management

- Site to Site Comparison

- Online Reviews with HCO Fleet Expert

- Fleet Optimization

- MHE Quote Comparison Tool

- Discounted Workplace Safety Assessment

- Annual Workplace Safety Assessments

Enterprise

- Centralized Fleet Data Management

- Real-time Visibility

- Maintenance Cost Tracking

- Lease Management

- Site to Site Comparison

- Online Reviews with HCO Fleet Expert

- Fleet Optimization

- MHE Quote Comparison Tool

- Discounted Workplace Safety Assessment

- Annual Workplace Safety Assessments

Frequently Asked Questions

Get Answers to Common Questions and Maximize the Value of Your Free Trial

What do I need to start the free trial?

Just your contact details and estimated fleet size. We’ll help you gather the fleet and maintenance data to get started.

Is the system compatible with all types of equipment?

Yes. The system supports all major types of forklifts and material handling equipment.

How secure is my data?

Your data is secured with state-of-the-art encryption technology. We prioritize your privacy and follow best practices for data protection.

Can I manage multiple locations through the portal?

Absolutely. The portal is designed for centralized management of multi-site warehouse fleets.

What happens after the trial period ends?

After your free trial, you’ll have the option to continue using the service with our flexible subscription model. We’ll notify you before your trial ends, and you can decide whether to proceed.

Ready To Get Started?

Take Control of Your Fleet Today – Start Your Free 30-Day Trial!

Sign up now and see how our warehouse fleet management software solutions can transform your operations.