Are you struggling with maintaining high order accuracy in your warehouse operations? Inefficient picking processes and human errors can often lead to mistakes and increased costs. Luckily, HCO Innovations has a solution for you – Automated Guided Vehicles (AGVs).

The Role of AGVs in Improving Order Accuracy

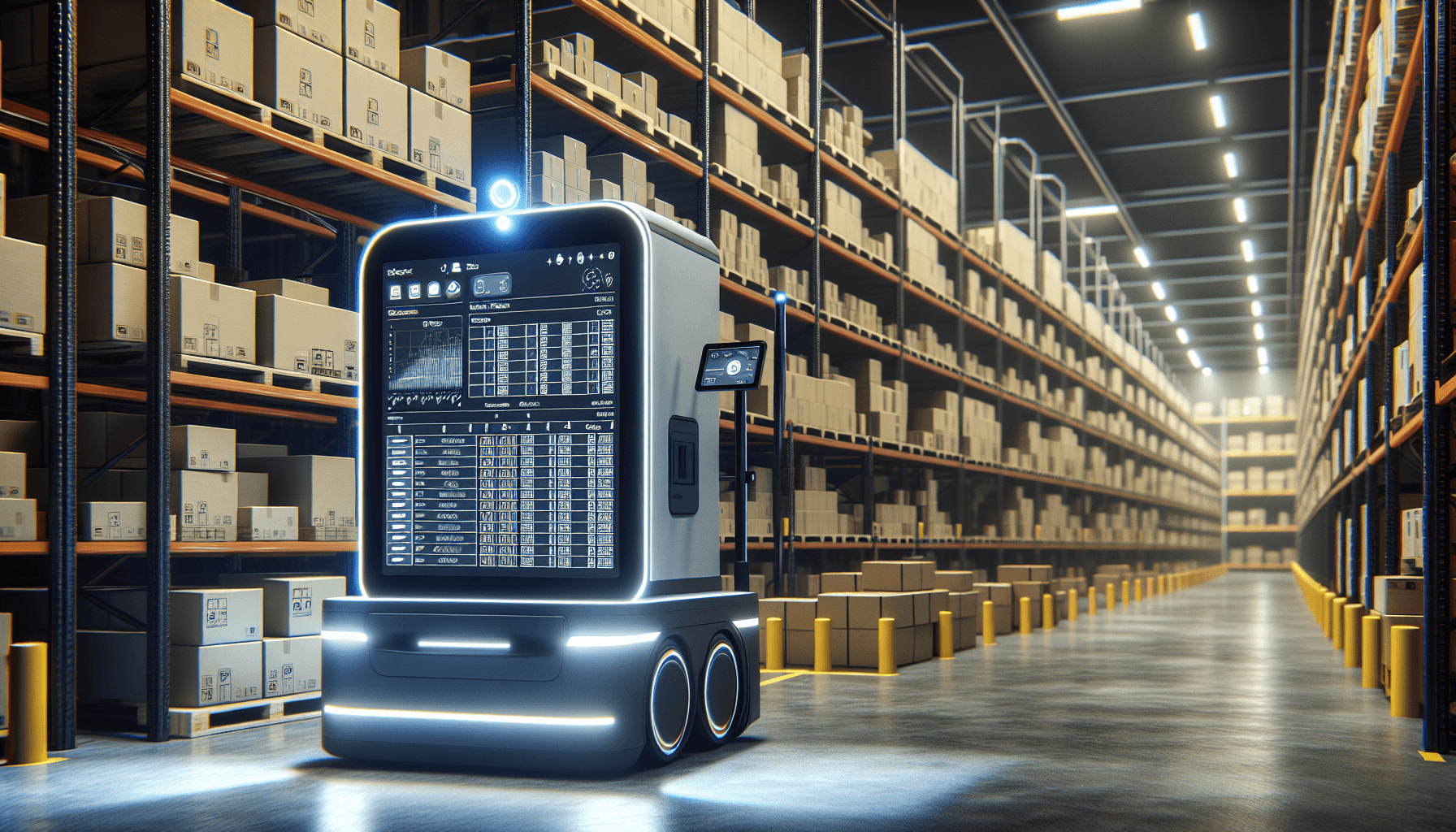

AGVs are robotic vehicles that are designed to autonomously navigate and perform tasks within a warehouse. They can move materials, manage inventory, and transport goods, all while improving efficiency and reducing errors. Here’s how AGVs can help improve order accuracy:

- Precision in Picking

- Real-Time Inventory Monitoring

- Optimized Routing

- Error Prevention

- Data-Driven Decision Making

AGVs are equipped with advanced sensors and cameras that allow them to accurately identify and pick the right items from the shelves. This eliminates the possibility of selecting the wrong products and reduces the chances of misplacing or damaging items during the picking process.

AGVs are connected to a central warehouse management system, enabling them to have real-time access to inventory data. This means they always know the exact location of each item and can update the system when items are picked or put away. This real-time monitoring helps prevent discrepancies between physical inventory and system records, leading to improved order accuracy.

AGVs use advanced algorithms to determine the most efficient routes for picking and transporting goods. By optimizing the routes, they can minimize travel time and ensure that items are delivered accurately and on time. This reduces the chances of mix-ups or delays in fulfilling orders.

AGVs are programmed to follow strict operating procedures, minimizing the possibility of errors. They are designed to perform tasks precisely and consistently, reducing the likelihood of mistakes caused by human factors such as fatigue or distraction. This leads to increased order accuracy and customer satisfaction.

AGVs collect valuable data throughout their operations, such as order fulfillment time, pick accuracy, and inventory levels. This data can be analyzed to identify areas for improvement and make data-driven decisions to optimize processes further. By continuously fine-tuning operations based on insights from AGV data, warehouse managers can achieve higher order accuracy rates.

When you deploy AGVs in your warehouse operations, you can significantly enhance your order accuracy and reduce costly errors. HCO Innovations specializes in warehouse optimization and offers state-of-the-art AGV solutions tailored to meet your specific needs.

Visit the HCO Innovations website to learn more about how AGVs can revolutionize your warehouse operations here.

Don’t let order accuracy be a challenge in your warehouse. Embrace the power of AGVs and take your operations to the next level!