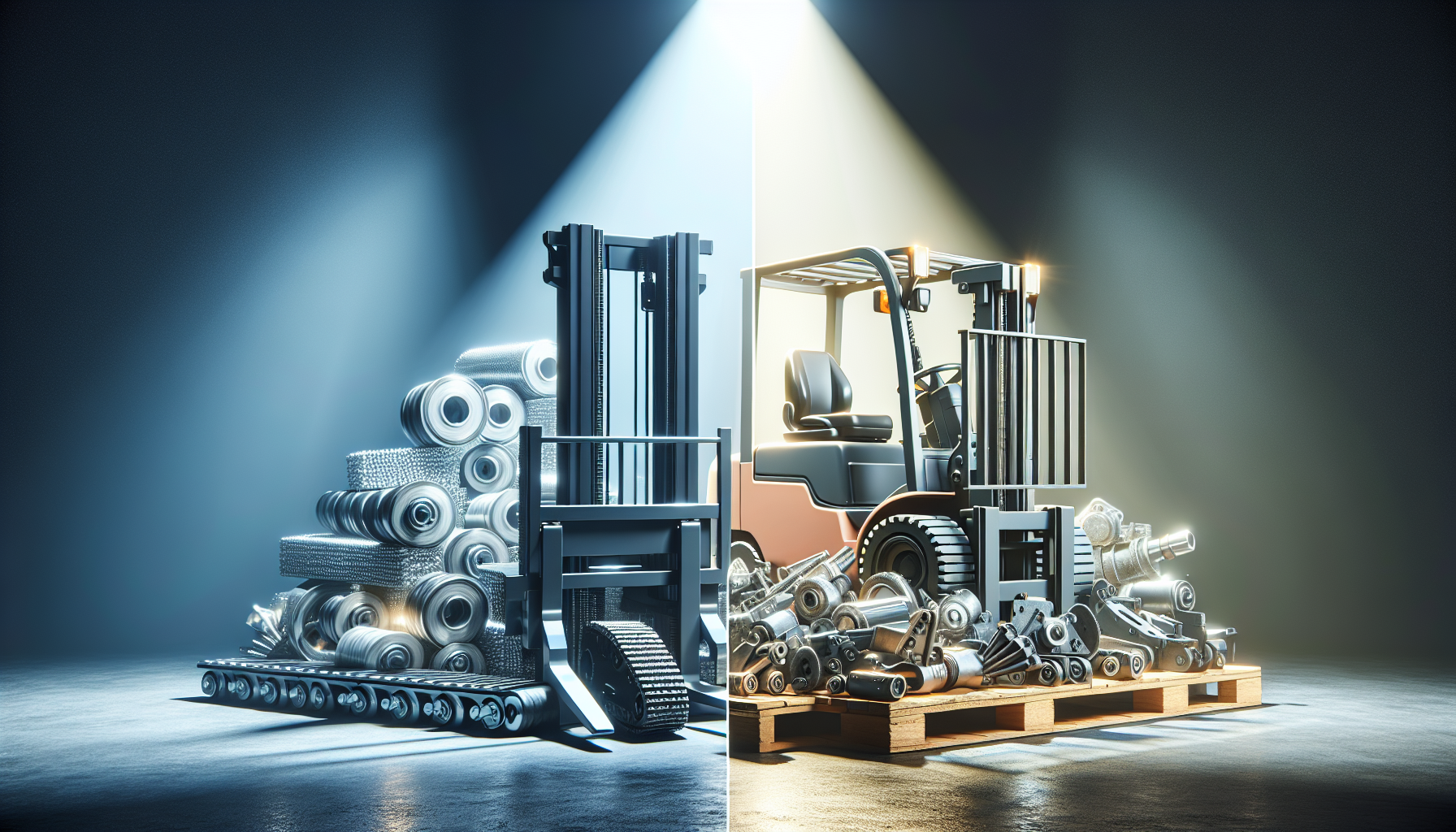

When it comes to optimizing your warehouse operations, one crucial aspect to consider is the choice between new and used material handling equipment. Material handling equipment plays a vital role in ensuring the smooth flow of goods within your warehouse, enhancing productivity and efficiency. However, deciding whether to invest in new or used equipment can be a challenging decision. In this article, we will explore the key factors to consider when choosing between new and used material handling equipment to help you make an informed decision for your warehouse.

Reliability and Performance

Reliability and performance are crucial considerations when it comes to choosing material handling equipment. New equipment offers the advantage of being brand new and unused, typically backed by a manufacturer’s warranty. This assurance of quality and reliability can be beneficial in ensuring smooth operations and minimizing downtime. New equipment is also likely to offer the latest technological advancements, which can enhance performance and efficiency.

On the other hand, used equipment may have a lower upfront cost but may come with the risk of potential wear and tear. It is important to thoroughly inspect used equipment and understand its maintenance history before making a purchasing decision. By choosing a reputable provider like HCO Innovations, who specializes in warehouse optimization solutions, you can ensure that any used equipment you purchase has been properly tested and inspected, minimizing the risk of reliability issues.

Cost Considerations

Cost is another major factor to consider when choosing between new and used material handling equipment. New equipment generally comes with a higher upfront cost compared to used equipment. However, it is important to consider the long-term costs and potential return on investment.

New equipment tends to have a longer lifespan and can offer better efficiency, reducing operating costs in the long run. In addition, new equipment may require less frequent maintenance and repairs, saving on ongoing expenses. Used equipment, although offering a more affordable initial cost, may require more frequent maintenance and repairs, which can add up over time.

It is crucial to evaluate your specific needs, budget, and projected usage before making a decision. By analyzing factors such as expected lifespan, maintenance costs, and potential resale value, you can determine whether the upfront cost of new equipment outweighs the potential savings of used equipment.

Availability and Customizability

Another consideration when choosing material handling equipment is availability and customizability. New equipment is generally readily available from manufacturers and suppliers, offering a wide range of models, sizes, and features to choose from. This allows you to select equipment that specifically meets your warehouse needs and requirements. Additionally, new equipment can often be customized or tailored to fit your unique warehouse layout and operations.

Used equipment, on the other hand, may have more limited availability and customization options. The selection of used equipment can vary depending on the market and availability of pre-owned equipment. However, with a reputable provider like HCO Innovations, you can still access a wide range of high-quality used equipment that has been refurbished and fully tested.

It is important to assess your specific warehouse requirements and weigh the availability and customizability options before making a decision. Consider factors such as the size of your warehouse, the type of goods being handled, and any specific features or functionalities that are essential for your operations.

Environmental Considerations

In recent years, sustainability and environmental considerations have become increasingly important for businesses. Choosing used material handling equipment can contribute to sustainability efforts by reducing the demand for new manufacturing and limiting waste. By investing in refurbished and properly maintained equipment, you are extending its lifespan and minimizing environmental impact.

However, it is important to note that new equipment may incorporate the latest energy-efficient technologies, reducing energy consumption and carbon footprint. It is essential to balance your environmental goals with other factors such as reliability, performance, and long-term costs to make the best decision for your warehouse operations.

In conclusion, choosing between new and used material handling equipment requires careful consideration of various factors. While new equipment offers the benefits of reliability, performance, and customizability, used equipment can be a cost-effective option with potential sustainability advantages. By assessing your specific needs, budget, and long-term goals, you can make an informed decision that aligns with your warehouse optimization objectives. For a wide range of material handling equipment options and expert advice, visit HCO Innovations, where they specialize in enhancing safety, productivity, efficiency, and cost-effectiveness within warehouse operations.

1. Is it better to buy new or used material handling equipment?

Choosing between new and used material handling equipment ultimately depends on your specific needs and budget. New equipment generally comes with the latest technology and warranty coverage, but it can be more expensive. Used equipment, on the other hand, may be more affordable, but it may have limited warranty coverage and potential wear and tear. Assess your requirements and budget to make the best decision.

2. What factors should I consider when deciding between new and used equipment?

Several factors should be taken into account, including budget, the specific needs of your business, the expected equipment usage, and the availability of maintenance and support services. New equipment may offer better productivity and longer lifespan, while used equipment may be a suitable option if you have a limited budget or temporary need.

3. Are there any risks associated with buying used material handling equipment?

Buying used equipment comes with a few risks. It is crucial to thoroughly inspect the equipment, inquire about its maintenance history, and run tests if possible. There is a possibility of hidden defects or future maintenance issues. Research reputable sellers and consider purchasing from a certified reseller to minimize these risks.

4. Can I save money by buying used material handling equipment?

Yes, purchasing used material handling equipment can often lead to cost savings. Pre-owned equipment is typically priced lower than new ones. However, it is important to consider factors such as maintenance costs, potential repairs, and the overall lifespan of the equipment before making a decision.

5. Do used equipment sellers offer any warranties?

Some used equipment sellers may offer limited warranties or guarantees on the equipment they sell. It's essential to inquire about warranty options and read the fine print carefully. Understanding the warranty coverage will provide insights into the level of support you can expect and the duration of the coverage.

6. Should I consider leasing material handling equipment instead of buying?

Leasing material handling equipment can be a viable option for businesses with fluctuating demands or tight budgets. Leasing allows for greater flexibility, access to the latest equipment models, and potential tax benefits. Consider the specific needs of your business, financial situation, and the length of equipment usage to determine if leasing is the right choice.

7. How can I ensure the used equipment I purchase is reliable and in good condition?

Prioritize inspections and due diligence when purchasing used material handling equipment. Physically examine the equipment, run tests if possible, and review maintenance records. If feasible, consult with a professional or equipment technician to ensure the equipment is in good working condition. Research reputable sellers and read customer reviews to gain further insights.

8. Can I negotiate the price when buying used material handling equipment?

Yes, you can often negotiate the price when purchasing used material handling equipment. Depending on the seller, the condition of the equipment, and market factors, there may be room for negotiation. It's always worth attempting to negotiate to potentially secure a better deal or additional value-added services.

9. Are there any specific types of material handling equipment that are more suitable to buy new?

The suitability of buying new or used equipment depends on various factors, including the type of equipment. Certain equipment, such as complex automated systems or equipment with advanced technology, may be more suitable to buy new for improved reliability and compatibility. Evaluate the specific features and requirements of the equipment in question to determine if new is the better option.

10. Are there any advantages to buying new material handling equipment?

Purchasing new material handling equipment offers several advantages. It often comes with the latest features, technology advancements, and improved efficiency. New equipment generally includes warranties and after-sales support, providing peace of mind. Additionally, you have the opportunity to customize the equipment to meet your specific requirements.

Remember, when choosing between new and used material handling equipment, consider factors such as budget, specific needs, equipment reliability, and long-term costs. It's recommended to assess each option on a case-by-case basis to make an informed decision.

Benefits of Renting Material Handling Equipment for Short-Term Projects

When it comes to short-term projects that require material handling, renting equipment is often the most practical and cost-effective solution. Whether you are in the construction, manufacturing, or logistics industry, having access to the right material handling equipment is crucial for smooth operations. In this article, we will discuss the benefits of renting material handling equipment for short-term projects and why HCO Innovations is the ideal partner for your equipment rental needs.

Flexibility and Cost-Effectiveness

One of the key advantages of renting material handling equipment for short-term projects is the flexibility it offers. Every project is unique, and the equipment requirements can vary significantly. Renting allows you to tailor your equipment needs to the specific project requirements. Instead of investing in expensive equipment that may only be used for a short duration, you can choose to rent the equipment for the exact duration of the project. This helps in optimizing costs and avoiding unnecessary expenses.

By renting from HCO Innovations, you can also save on maintenance and storage costs. When you own equipment, you are responsible for its maintenance, repairs, and storage when not in use. By renting, you eliminate these additional expenses and can focus on the project at hand. HCO Innovations ensures that all rental equipment is well-maintained and in excellent working condition, so you can be confident in its reliability.

Access to a Wide Range of Equipment

HCO Innovations offers a comprehensive fleet of material handling equipment for rental purposes. From forklifts and pallet jacks to conveyors and scissor lifts, they have a wide range of equipment to meet your specific project needs. With access to a diverse fleet, you can choose the right equipment for the job, ensuring efficiency and productivity. Additionally, HCO Innovations regularly updates their rental inventory to offer the latest and most advanced equipment, allowing you to benefit from the latest technological advancements in material handling.

Whether you need equipment for lifting heavy loads, transporting materials, or optimizing warehouse operations, HCO Innovations has the right solution for you. Their experts can guide you in selecting the most suitable equipment for your project, taking into consideration factors such as load capacity, maneuverability, and safety features.

Expert Guidance and Support

When you choose HCO Innovations as your material handling equipment rental partner, you can expect expert guidance and support throughout the duration of your project. Their team of experienced professionals has in-depth knowledge of different industries and can provide valuable insights and recommendations for optimizing your material handling processes.

Furthermore, HCO Innovations offers on-site support and training to ensure that you and your team are proficient in using the rented equipment safely and effectively. This comprehensive support ensures that your project runs smoothly and minimizes the risk of accidents or delays caused by improper equipment usage.

By renting from HCO Innovations, you can benefit from their commitment to customer satisfaction. They prioritize understanding your unique project requirements and strive to provide tailored solutions that meet your specific needs. Their personalized approach sets them apart from other equipment rental providers and ensures that you receive the highest level of service and support.

Conclusion

Opting to rent material handling equipment for short-term projects offers numerous benefits, including flexibility, cost-effectiveness, and access to a wide range of equipment. HCO Innovations, with their extensive fleet of well-maintained equipment and expert support, is the perfect partner for your equipment rental needs. By renting from HCO Innovations, you can focus on your project while ensuring efficient material handling processes and significant cost savings. To learn more about HCO Innovations and their services, visit their website now.