In today’s fast-paced business world, efficiency and productivity are key factors in ensuring the success of any industry. One area where these factors play a crucial role is in material handling. Whether you are in manufacturing, distribution, or any other industry that requires the movement of goods, choosing the right material handling equipment (MHE) is essential. The right equipment can not only improve safety and productivity but also help reduce costs and streamline operations.

Understanding Your Material Handling Needs

The first step in choosing the best MHE for your industry is to understand your specific material handling needs. Take the time to assess your operations and identify the types of materials you handle, the volume of materials, and the specific tasks involved. This will help you determine the most appropriate types of equipment for your needs.

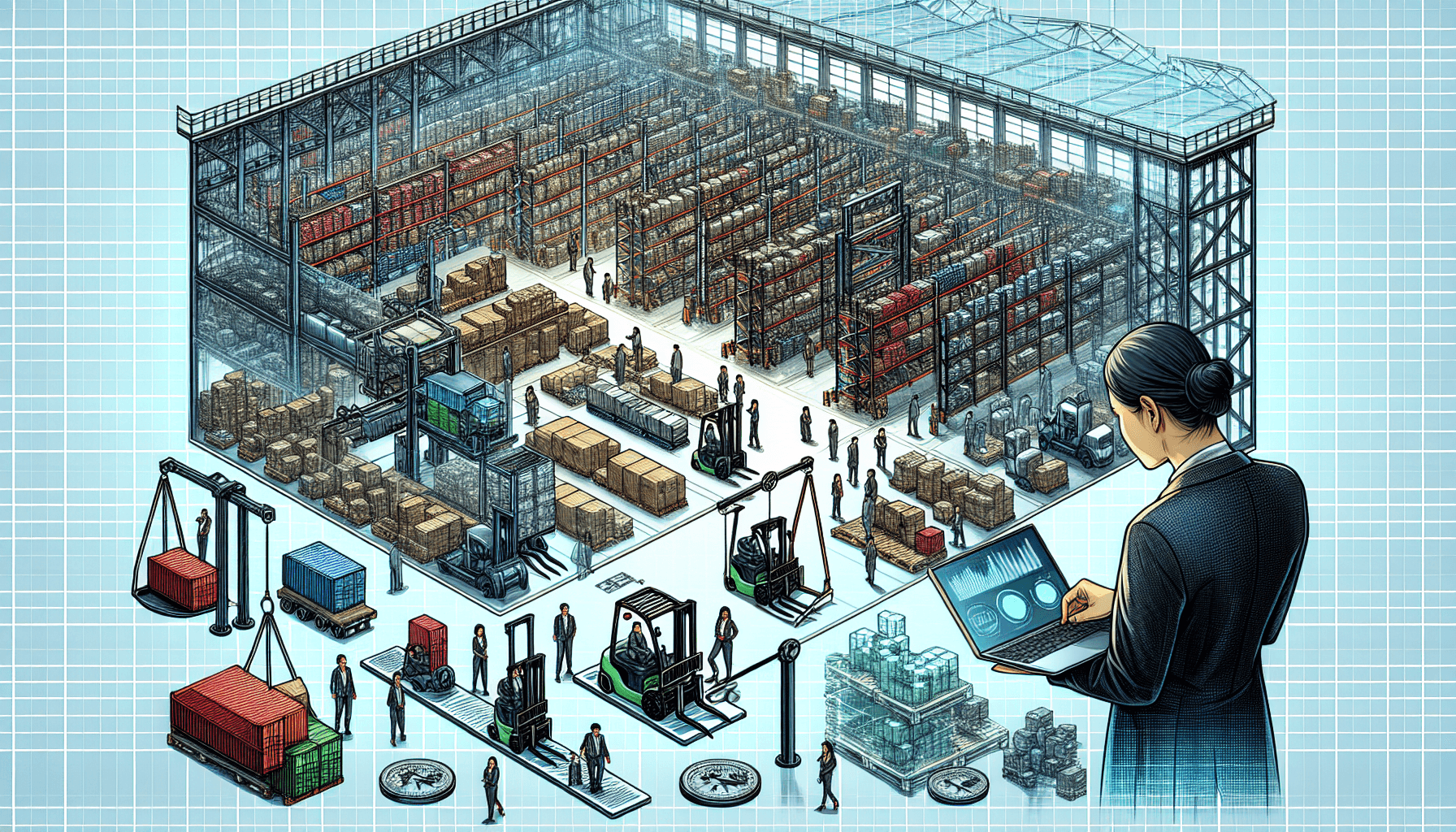

For example, if you are in the manufacturing industry and deal with heavy machinery or large components, you may need specialized equipment such as forklifts or cranes. On the other hand, if you are in the retail industry and deal with smaller items, you may require equipment like conveyor belts or pallet jacks for efficient movement.

Evaluating Different Types of Material Handling Equipment

Once you have a clear understanding of your material handling needs, it’s time to explore the different types of equipment available. Here are some common types of MHE to consider:

- Forklifts: Forklifts are versatile machines that can handle a wide range of materials. They are particularly useful for lifting and transporting heavy objects.

- Conveyor Systems: Conveyor systems are ideal for industries that require the continuous movement of materials. They can be customized to fit your specific needs and can greatly improve efficiency and productivity.

- Pallet Jacks: Pallet jacks are manual or electric tools used to lift and move pallets. They are cost-effective and easy to use for smaller scale operations.

- Cranes: Cranes are heavy-duty machines used for lifting and moving extremely heavy objects. They are commonly used in construction, manufacturing, and shipyards.

- Scissor Lifts: Scissor lifts are used for lifting workers or materials to elevated heights. They are commonly used in warehouses and distribution centers.

These are just a few examples of the wide range of equipment available. It’s important to thoroughly research and evaluate each type to determine which one best meets your specific needs. Consider factors such as cost, versatility, ease of use, and maintenance requirements.

Partnering with a Warehouse Optimization Solutions Provider

Choosing the right MHE for your industry can be a complex process. That’s why it’s often beneficial to partner with a warehouse optimization solutions provider like HCO Innovations. With their expertise and industry knowledge, they can help you navigate through the options and find the best equipment for your specific needs.

HCO Innovations offers a wide range of solutions for warehouse optimization, including MHE management. They have a team of experts who can assess your operations, analyze your needs, and recommend the most suitable equipment. They understand the importance of safety, productivity, efficiency, and cost-effectiveness within warehouse operations and can provide customized solutions tailored to your industry.

By partnering with HCO Innovations, you can gain access to the latest technology and innovations in material handling equipment. They stay up to date with industry trends and advancements, ensuring that you are equipped with the most efficient and reliable equipment available.

In conclusion, choosing the best MHE for your industry is a crucial decision that can greatly impact your operations. By understanding your material handling needs, evaluating different types of equipment, and partnering with a warehouse optimization solutions provider like HCO Innovations, you can optimize your warehouse operations, improve productivity, and ultimately drive the success of your business.

For more information on material handling equipment management and warehouse optimization solutions, please visit HCO Innovations.