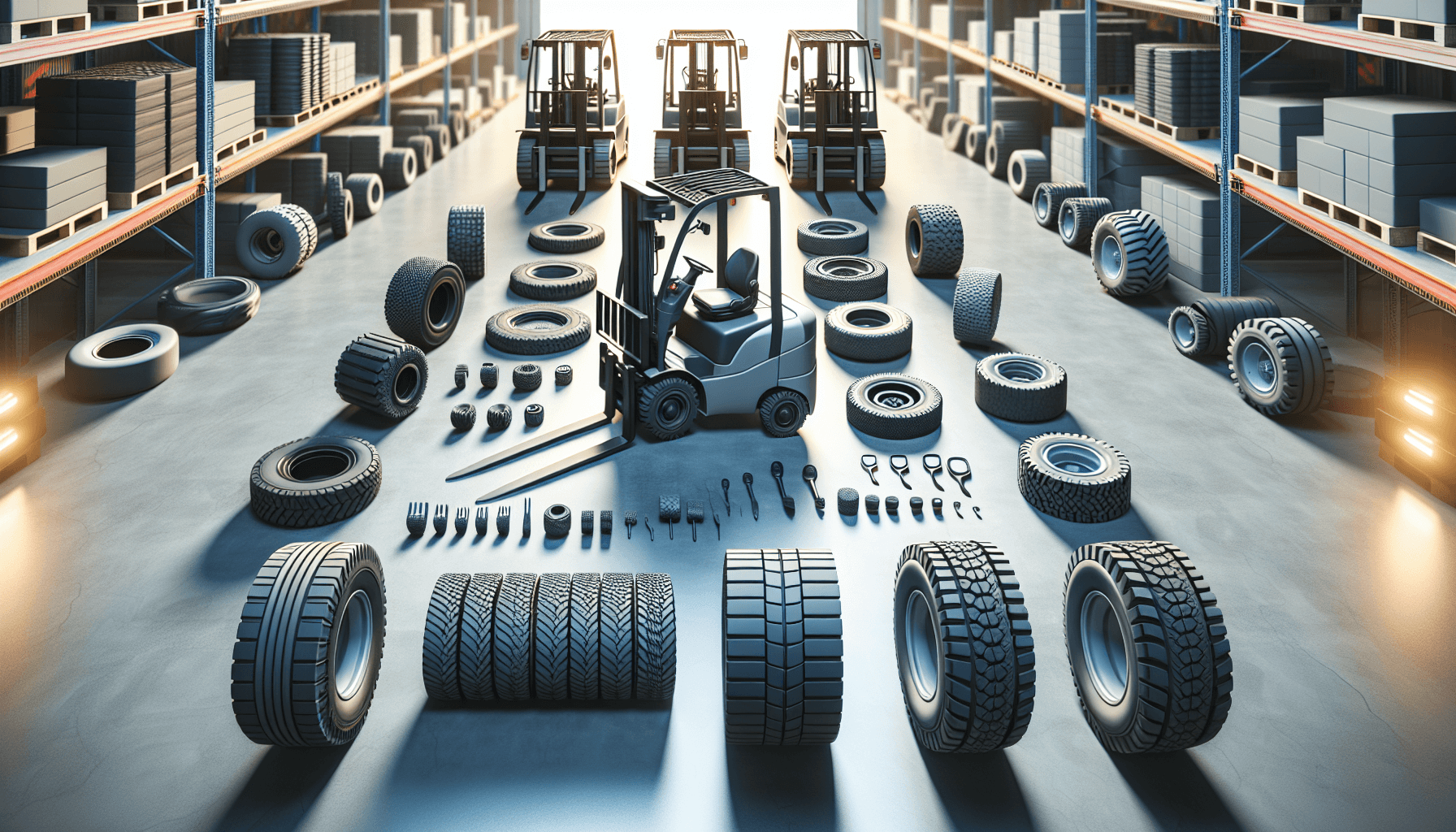

If you own or manage a fleet of forklifts, one of the most important considerations is choosing the right tires for your machines. Forklift tires play a crucial role in the performance, safety, and efficiency of your equipment. The wrong tires can lead to increased downtime, reduced productivity, and unnecessary costs.

Why Choosing the Right Forklift Tires is Important

Before delving into the process of choosing the right forklift tires, let’s discuss why it is important to make the right selection:

- Safety: The right tires are essential for ensuring safety in your operation. Different types of tires offer varying levels of traction and stability, which are crucial for preventing accidents and minimizing the risk of tip-overs.

- Productivity: Choosing tires that are suitable for your application can significantly impact the productivity of your forklift fleet. The right tires can help improve maneuverability, reduce tire wear, and enhance overall efficiency.

- Cost-efficiency: Opting for the right forklift tires can save you money in the long run. Tires that are well-suited for your application and working conditions will last longer, require less maintenance, and minimize the need for frequent tire replacements.

- Operator Comfort: The right tires can contribute to the comfort of the forklift operator. Certain types of tires offer better shock absorption and noise reduction, providing a smoother ride and reducing operator fatigue.

Now that we understand the importance of choosing the right forklift tires, let’s dive into the factors you need to consider:

Tire Type

The first step in selecting the right forklift tires is determining the appropriate tire type for your specific application. The two main options are:

- Pneumatic Tires: Pneumatic tires are similar to car tires and are filled with air. They provide excellent traction and are suitable for outdoor applications or uneven surfaces. Pneumatic tires can handle rough terrain, debris, and even small obstacles. However, they are not recommended for indoor use on smooth warehouse floors.

- Cushion Tires: Cushion tires are made of smooth rubber and are ideal for indoor use on smooth surfaces such as concrete or asphalt. They offer better stability, maneuverability, and are more cost-effective compared to pneumatic tires. However, cushion tires are not designed for outdoor use or rough terrain.

Your choice between pneumatic and cushion tires will depend on your specific working environment, whether it’s primarily indoor or outdoor, the type of surface, and the nature of the loads you handle.

Tire Tread

Another crucial consideration when choosing forklift tires is the tread pattern. The tread pattern affects traction, stability, and the ability to grip different surfaces. Here are the main tread options:

- Smooth Tires: Smooth tires have no tread pattern and are generally used for indoor applications on clean, flat surfaces. They provide better maneuverability and are ideal for warehouses or manufacturing facilities with smooth concrete floors.

- Traction Tires: Traction tires feature a lug tread pattern that provides excellent grip on loose or uneven surfaces. These tires are suitable for outdoor applications, especially in areas with gravel, dirt, or snow.

- Ribbed Tires: Ribbed tires have a ribbed or semi-smooth tread pattern that offers a balance between smooth tires and traction tires. They provide a moderate level of grip and are often used in light-duty indoor applications or on surfaces where some traction is necessary.

Consider the surfaces your forklifts will operate on and the type of loads they will handle when choosing the tread pattern. This will ensure optimal performance and safety in your particular operating conditions.

Load Capacity and Tire Size

The load capacity of your forklifts and the tire size are interconnected factors that must be considered together. The tires should be capable of supporting the maximum load capacity of the forklifts while ensuring stability and balance. Using undersized or oversized tires can cause instability, premature tire wear, and potential damage to your equipment.

Refer to the forklift manufacturer’s specifications or consult with a professional to determine the correct tire size and load capacity for your specific forklift models.

Consider Your Operating Environment

Lastly, when selecting forklift tires, consider the operating environment and the conditions your forklifts will encounter. Factors to consider include:

- Indoor vs. Outdoor: Determine whether your forklifts will primarily be used indoors or outdoors. This will help you decide between cushion tires (indoor) and pneumatic tires (outdoor).

- Surface Conditions: Assess the condition of the surfaces your forklifts will operate on. Determine if they are smooth, uneven, or require special tires (such as non-marking tires for clean, finished floors).

- Climate: Consider the climate and weather conditions your forklifts will be exposed to. Extreme temperatures, rain, snow, or ice may require specific tire types for optimum performance and safety.

Overall, it is crucial to select forklift tires that are designed to withstand the specific demands of your operating environment while maximizing performance, safety, and efficiency.

If you need assistance selecting the right forklift tires or managing your forklift fleet efficiently, consider reaching out to a reliable forklift fleet management provider like HCO Innovations. They offer expert guidance and solutions to optimize your fleet’s performance, including tire selection, maintenance, and overall fleet management. Click here to learn more about their services.

In conclusion, choosing the right forklift tires is crucial for the safety, productivity, and cost-efficiency of your fleet. Consider factors such as tire type, tread pattern, load capacity, tire size, and operating environment to make an informed decision. Taking the time to assess these factors and consult with experts will ensure that your forklifts are equipped with the most suitable tires for your specific needs.

What are the different types of forklift tires available?

There are three main types of forklift tires: pneumatic, solid, and cushion. Pneumatic tires are similar to car tires and are ideal for outdoor use. Solid tires are made from solid rubber and are best suited for indoor applications. Cushion tires are made of solid rubber and are designed for use on smooth, indoor surfaces.

How do I determine the right tire size for my forklift?

To determine the right tire size for your forklift, you need to consider the forklift's load capacity and the surface it will be operating on. It's important to check the forklift's manufacturer specifications and consult with a tire specialist to ensure you select the correct tire size.

When should I replace my forklift tires?

You should consider replacing your forklift tires when they are worn down to the wear line indicator or if you notice uneven wear, cracks, or other signs of damage. Regularly inspecting your tires and following the manufacturer's recommendations is crucial for maintaining a safe and efficient fleet.

What is the difference between regular tires and forklift tires?

Regular tires are designed for use on vehicles that travel on roads and highways, while forklift tires are specifically designed to support heavy loads and withstand the unique operating conditions of forklifts. Forklift tires are usually made of durable rubber compounds to provide better stability, traction, and load-bearing capabilities.

Should I choose pneumatic or solid tires for my forklift?

The choice between pneumatic and solid tires depends on your specific application and working environment. If your forklift primarily operates outdoors or on rough terrain, pneumatic tires offer better shock absorption and traction. If your forklift operates exclusively indoors on smooth surfaces, solid tires are a more cost-effective and maintenance-free option.

Can I switch between different tire types on my forklift?

In most cases, it is possible to switch between different tire types on a forklift. However, it is important to consult with a tire specialist or the forklift manufacturer to ensure compatibility and to understand any implications or adjustments that may be required.

How often should I inspect my forklift tires for wear and tear?

Regular inspections of your forklift tires are crucial for maintaining a safe working environment. It is recommended to inspect your tires at least once a month, looking for signs of wear, cuts, punctures, and other damage. Additionally, perform thorough inspections before any intensive usage or after any significant impacts.

What are the advantages of cushion tires?

Cushion tires provide several advantages, especially for indoor operations. They offer a smaller turning radius, making them ideal for maneuvering in tight spaces. Cushion tires also have a lower profile, allowing for better visibility and enhanced stability. They provide a comfortable ride and are generally more cost-effective than pneumatic tires.

How do I ensure I'm choosing the right tires for my forklift fleet?

To ensure you choose the right tires for your forklift fleet, consider factors such as the working environment, load capacity requirements, surface conditions, and budget. Consulting with a tire specialist or contacting the forklift manufacturer can provide valuable guidance and help you make an informed decision.

What maintenance steps should I take to extend the lifespan of my forklift tires?

To extend the lifespan of your forklift tires, regularly inspect them for signs of damage or wear, maintain proper tire pressure, avoid overloading your forklifts, and ensure your operators use the appropriate driving techniques. Implementing a preventive maintenance program, which includes regular tire rotations and replacements when necessary, is also essential to prolong their lifespan.

The effects of different forklift tire types on productivity and safety.

When it comes to warehouse optimization and forklift fleet management, there are several factors that can significantly impact productivity and safety. One critical factor that often goes overlooked is the type of tires used on forklifts. Forklift tires play a vital role in ensuring smooth operations and minimizing the risk of accidents in a warehouse environment.

The Importance of Choosing the Right Forklift Tire

Choosing the right type of forklift tire is crucial for both productivity and safety. The type of tire used can affect various aspects of forklift performance, including traction, stability, maneuverability, and load capacity. Here are some key factors to consider when selecting the appropriate forklift tire:

- Tire Type: There are three common types of forklift tires: pneumatic, cushion, and solid. Pneumatic tires are similar to those used on cars and trucks, offering excellent shock absorption and traction. Cushion tires are made of solid rubber and are ideal for indoor use on smooth surfaces. Solid tires are puncture-proof and are suitable for heavy-duty outdoor applications.

- Surface Conditions: The type of tire you choose should depend on the surface conditions in your warehouse. If your facility has uneven or rough surfaces, pneumatic tires provide better traction and shock absorption. On the other hand, cushion or solid tires are more suitable for smooth and even surfaces.

- Load Capacity: The load capacity of the forklift and the expected weight of the loads being lifted are essential considerations when selecting tires. Pneumatic tires have higher load capacities compared to cushion tires, making them suitable for heavy-duty applications.

- Indoor vs. Outdoor Use: If your forklift operates both indoors and outdoors, you may need to consider a tire that performs well in different environments. Pneumatic or cushion tires are often the preferred choice as they provide a balance between indoor and outdoor performance.

Once you have identified the appropriate tire type for your forklifts, it is important to ensure they are properly maintained. Regular tire inspections and maintenance help prolong the lifespan of the tires and prevent unexpected issues that can disrupt operations.

The Effects of Forklift Tire Types on Productivity

The choice of forklift tire can have a significant impact on productivity in a warehouse setting. Here are some ways in which different tire types can affect productivity:

- Traction: Pneumatic tires offer excellent traction, especially on rough or uneven surfaces. This means forklift operators can navigate through the warehouse more efficiently, reducing the time required to transport goods from one location to another.

- Stability: The stability of the forklift is crucial for safe and efficient operation. Pneumatic tires provide better stability due to their ability to absorb shocks and vibrations, making them ideal for handling heavy loads or operating in outdoor environments.

- Maneuverability: Forklifts with the right tires can easily maneuver in narrow aisles or tight spaces, allowing operators to maximize the available storage capacity and optimize the layout of the warehouse. This improves overall efficiency and reduces the risk of accidents.

- Noise: Forklifts with cushion or solid tires tend to produce less noise compared to those with pneumatic tires. This can be beneficial in indoor environments where excessive noise can be a distraction or cause discomfort to employees.

By selecting the most suitable tire type for your forklift fleet, you can improve productivity by enhancing traction, stability, maneuverability, and reducing noise levels in your warehouse operations.

The Effects of Forklift Tire Types on Safety

Warehouse safety is of paramount importance, and the choice of forklift tire can significantly impact the safety of operations. Here's how different tire types can affect safety:

- Grip and Traction: Pneumatic tires are known for their excellent grip and traction, enabling forklifts to maintain stability while carrying loads. This reduces the risk of accidents caused by slipping or skidding.

- Load Stability: Forklift tires that provide good stability and shock absorption help keep the loads steady during transportation. This reduces the likelihood of load shifts or tip-overs, enhancing overall safety.

- Control: The right set of tires can improve the control and handling of the forklift. This allows operators to respond quickly to any unexpected obstacles or hazards, reducing the risk of collisions or damage to goods and equipment.

- Operator Comfort: Forklift operators spend long hours on their equipment, and the comfort of their working environment is crucial. Pneumatic tires, with their shock-absorbing properties, provide a smoother ride, reducing operator fatigue and improving alertness.

By prioritizing safety and selecting the appropriate forklift tire type, you can minimize the risk of accidents, injuries, and equipment damage in your warehouse.

At HCO Innovations, we understand the importance of optimizing every aspect of your warehouse operations, including forklift tire selection. Our team of experts can help assess your warehouse needs and recommend the most suitable tire type for your forklift fleet, considering factors such as surface conditions, load capacity, and indoor/outdoor usage. We offer comprehensive warehouse optimization solutions that deliver exceptional ROI, helping you reduce material handling costs and improve operational efficiency.

If you're looking to enhance productivity and safety in your warehouse, contact HCO Innovations today. Our tailored solutions and cutting-edge technology will help you achieve significant cost reductions and optimize your warehouse operations for long-term success.