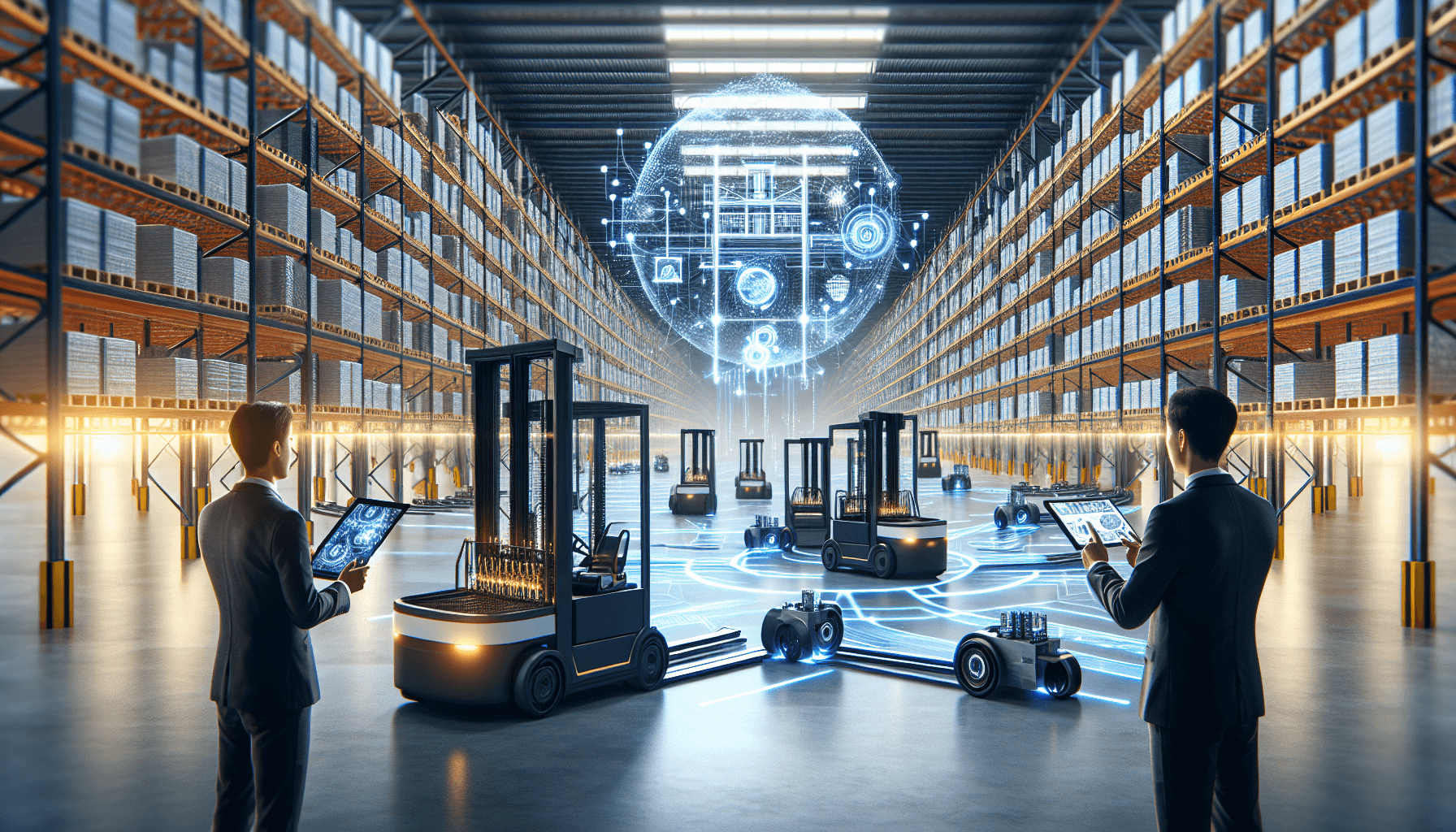

Implementing automated guided vehicles (AGVs) in your warehouse can significantly enhance efficiency and productivity, leading to improved customer satisfaction and increased profits. However, a successful AGV implementation project requires careful planning and execution. In this article, we will guide you through the key steps to conduct a successful AGV implementation project in your warehouse.

Step 1: Define Your Objectives and Requirements

Before embarking on an AGV implementation project, it is crucial to clearly define your objectives and requirements. Ask yourself what specific goals you want to achieve with AGVs in your warehouse. Are you aiming to improve operational efficiency, reduce labor costs, increase inventory accuracy, or enhance safety? Once you have identified your objectives, determine the specific requirements your AGVs need to fulfill. Consider factors such as load capacity, speed, navigation capabilities, and integration with existing systems.

Step 2: Conduct a Thorough Site Assessment

Next, conduct a thorough site assessment to evaluate your warehouse’s suitability for AGV implementation. Consider factors such as floor space, layout, obstacles, and infrastructure. Assess whether any modifications or upgrades are necessary to accommodate AGVs. Additionally, analyze your existing workflow and identify areas that would benefit the most from AGV integration. Understanding your warehouse’s current state will help you design an effective AGV system.

Step 3: Select the Right AGV Supplier

Choosing the right AGV supplier is crucial for the success of your implementation project. Look for a reputable supplier with a proven track record in warehouse optimization and AGV deployments. Evaluate their experience, industry expertise, and customer reviews. A reliable supplier will guide you through the entire implementation process, from system design to installation and training. HCO Innovations, a prominent provider of warehouse optimization solutions, offers comprehensive AGV deployment services. Visit their website for more information on warehouse AGV deployment.

Step 4: Develop a Detailed Implementation Plan

Create a detailed implementation plan that outlines the specific tasks, timelines, and responsibilities involved in the project. Break down the project into manageable phases to ensure smooth execution. Define milestones and set realistic deadlines. Don’t forget to involve key stakeholders, including warehouse managers, IT personnel, and maintenance staff, in the planning process. Regular communication and coordination are essential for a successful implementation.

Step 5: Prepare Your Warehouse for AGV Integration

Before deploying AGVs, prepare your warehouse for integration. This may involve installing necessary infrastructure, such as AGV charging stations and RFID readers. Train your staff on AGV operations, including safety procedures and maintenance requirements. Ensure that your warehouse personnel are fully familiar with the new system to minimize disruptions and maximize efficiency during the implementation phase.

Step 6: Test and Optimize

Prior to full-scale deployment, conduct rigorous testing to ensure the smooth operation of your AGV system. Test the AGVs’ navigation capabilities, load handling capabilities, and integration with other systems. Identify and address any issues or inefficiencies that arise during the testing phase. Continuously optimize the system to achieve maximum warehouse productivity and efficiency.

Step 7: Monitor and Maintain

Once your AGV system is up and running, monitor its performance regularly. Track key performance indicators, such as productivity levels, error rates, and equipment utilization. Analyze the data to identify areas for further improvement. Perform regular maintenance to keep your AGVs in optimal condition. This includes battery maintenance, software updates, and preventive repairs. Regular monitoring and maintenance will ensure the long-term success of your AGV implementation.

In conclusion, implementing AGVs in your warehouse can revolutionize your operations and lead to significant improvements in safety, productivity, efficiency, and cost-effectiveness. By following the steps outlined in this article, you can conduct a successful AGV implementation project in your warehouse. Remember to define your objectives, assess your site, select the right supplier, develop a detailed plan, prepare your warehouse, test and optimize, and monitor and maintain your AGV system. With careful planning and execution, you can harness the power of AGVs to drive your warehouse towards greater success.