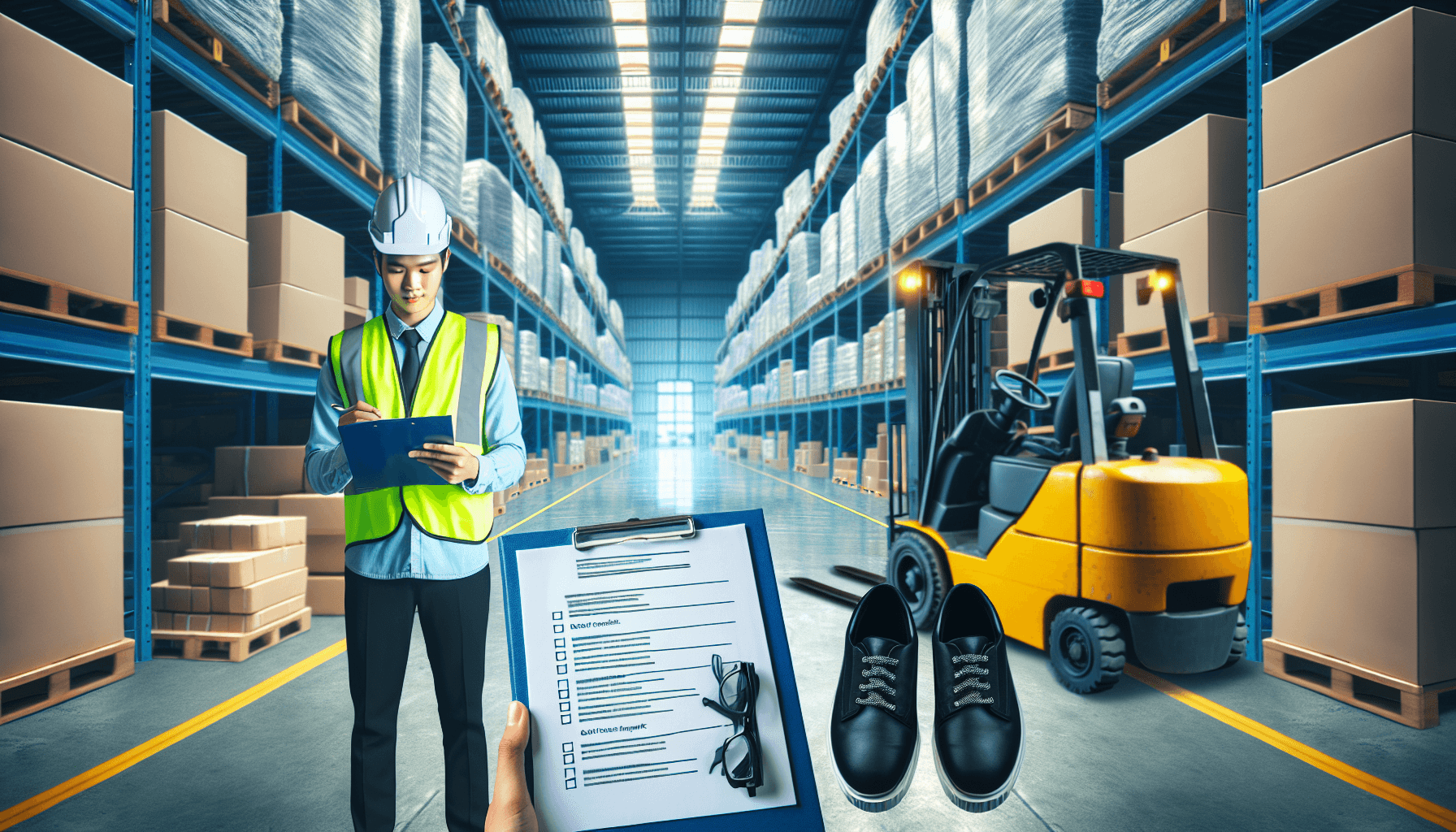

In the world of warehouse operations, safety should always be a top priority. Ensuring a safe working environment not only protects employees but also promotes productivity and efficiency within the warehouse. One effective way to maintain and improve safety standards is by conducting regular warehouse safety audits. These audits involve evaluating the current safety practices, identifying potential hazards, and implementing corrective measures. In this article, we will discuss how to conduct a warehouse safety audit and why it is crucial for the success of your warehouse operations.

Why Conduct a Warehouse Safety Audit?

Before we delve into the details of conducting a warehouse safety audit, let’s understand why it is essential. Safety audits help warehouse managers and operators identify potential risks and vulnerabilities within their operations. By proactively addressing these issues, they can prevent accidents, injuries, or damage to inventory and equipment. Additionally, safety audits enable companies to comply with industry regulations and maintain a positive reputation among employees, customers, and regulatory bodies.

Now, let’s look at the step-by-step process of conducting a warehouse safety audit.

Step 1: Prepare for the Audit

The first step in conducting a warehouse safety audit is to prepare for the process. This involves gathering relevant information, such as safety policies, procedures, and incident reports. Reviewing these documents will help you understand the current state of safety in your warehouse and identify any recurring issues or patterns that need to be addressed.

Step 2: Create an Audit Checklist

An audit checklist is a crucial tool that guides you through the entire auditing process. It helps ensure that you cover all aspects of safety and identify potential hazards. Your checklist should be comprehensive and cover areas such as equipment safety, storage practices, emergency procedures, training records, and more. Be sure to tailor the checklist to your specific warehouse operations and industry requirements.

Step 3: Conduct a Physical Inspection

Once you have prepared your checklist, it’s time to conduct a physical inspection of your warehouse. Walk through all areas of your warehouse, including storage areas, loading docks, aisles, and office spaces. Pay close attention to elements such as lighting, signage, flooring, ventilation, and fire safety measures. Look for any signs of potential hazards, such as blocked exits, loose wires, damaged equipment, or poorly maintained shelving units.

During the inspection, take detailed notes and photographs of any potential hazards or safety violations that you come across. These will serve as evidence and reference points later when determining corrective actions.

Step 4: Review Safety Procedures

As part of the safety audit, it’s crucial to review the effectiveness of your current safety procedures. Examine whether employees are following established safety protocols, such as wearing personal protective equipment (PPE), using proper lifting techniques, and following emergency response plans. Evaluate the training programs in place and assess if they adequately cover all safety-related topics.

Additionally, review incident reports and near-miss reports to identify any trends or common causes of accidents. This information will help you address root causes and develop targeted solutions to prevent similar incidents from recurring.

Step 5: Analyze the Data and Identify Areas for Improvement

Once you have gathered all the necessary information through inspections and reviewing safety procedures, it’s time to analyze the data and identify areas for improvement. Look for recurring issues, patterns, or high-risk areas that need immediate attention. It could be anything from inadequate training to lack of safety signage or outdated equipment.

Use the information collected to prioritize and develop action plans to address each identified issue. Ensure that the solutions are feasible, practical, and aligned with industry best practices. Assign responsibilities to individuals or teams for implementing each corrective action, and set realistic timelines for completion.

Step 6: Implement Corrective Actions

The real value of a safety audit lies in the implementation of corrective actions. Take the necessary steps to address the identified safety issues promptly. This may involve providing additional training to employees, replacing or repairing damaged equipment, improving lighting or ventilation, or updating safety policies and procedures.

To ensure successful implementation, communicate the findings of the safety audit and the corresponding action plans to all employees. Emphasize the importance of safety and encourage a culture of reporting hazards and near-miss incidents. Regularly monitor progress and provide support and resources as needed.

Step 7: Follow-Up and Continual Improvement

A safety audit is not a one-time event; it should be part of an ongoing process of continual improvement. Schedule regular follow-ups to reassess the effectiveness of implemented corrective actions and determine if further adjustments or improvements are needed.

Encourage open communication with employees and create mechanisms for reporting safety concerns or suggestions. Regularly review incident reports and near-miss records to identify any emerging trends or new areas of concern. Stay updated on industry best practices and changes in safety regulations, and incorporate them into your warehouse operations as needed.

In conclusion, conducting regular warehouse safety audits is crucial for maintaining a safe and productive working environment. By following the steps outlined in this article, you can identify potential hazards, implement corrective measures, and promote a culture of safety in your warehouse. Remember, safety should never be compromised, and a proactive approach to warehouse safety can lead to improved productivity, efficiency, and employee satisfaction.

For more information on how to conduct a warehouse safety audit, contact HCO Innovations, a leading provider of warehouse optimization solutions. Their expertise in enhancing safety, productivity, efficiency, and cost-effectiveness within warehouse operations can help you create a safer work environment and achieve optimal warehouse performance. Take the first step towards a safer warehouse by scheduling a warehouse safety evaluation with HCO Innovations here.

What is a warehouse safety audit?

A warehouse safety audit is a systematic process of evaluating and assessing the safety protocols and practices in a warehouse facility. It involves identifying potential hazards, evaluating compliance with safety regulations, and developing strategies to mitigate risks.

Why is conducting a warehouse safety audit important?

Conducting a warehouse safety audit is crucial because it helps to ensure the safety and well-being of employees, prevent accidents and injuries, comply with legal requirements, and maintain a productive work environment. Regular audits also help to identify areas for improvement and implement corrective measures.

Who should conduct a warehouse safety audit?

A warehouse safety audit should ideally be conducted by a qualified safety professional or a designated safety committee within the organization. These individuals should have a comprehensive understanding of warehouse operations, safety regulations, and auditing procedures.

How often should a warehouse safety audit be conducted?

The frequency of warehouse safety audits may vary depending on the size of the warehouse, the nature of the operations, and legal requirements. However, it is generally recommended to conduct annual audits as a minimum. Additional audits may be required after significant changes in operations, equipment, or safety regulations.

What are some common areas to focus on during a warehouse safety audit?

During a warehouse safety audit, it is important to focus on various areas such as fire safety measures, storage arrangements, material handling equipment, emergency response plans, employee training, hazard communication, and compliance with safety regulations. Additionally, specific areas prone to accidents or particular hazards should be given special attention.

How should I prepare for a warehouse safety audit?

Prior to the warehouse safety audit, it is important to review existing safety policies and procedures, evaluate previous audit reports, and ensure that all required documentation is up-to-date. It is also crucial to communicate the audit plans to warehouse staff, provide necessary training, and address any potential concerns or questions they may have.

What happens after a warehouse safety audit?

After a warehouse safety audit, the findings and recommendations should be documented and shared with the relevant stakeholders. It is essential to develop an action plan to address any identified issues, assign responsibilities, and set deadlines for implementation. Regular follow-ups should be conducted to monitor progress and ensure the effectiveness of corrective measures.

Can I conduct a warehouse safety audit on my own or should I hire an external professional?

While you can conduct a warehouse safety audit internally, it is often beneficial to seek the expertise of an external professional or consultant. They can provide an unbiased assessment, offer fresh perspectives, and bring in-depth knowledge of safety regulations and best practices. However, if you have qualified personnel with experience in safety auditing, you can conduct the audit internally.

Are there any legal implications of not conducting a warehouse safety audit?

Yes, there can be legal implications of not conducting a warehouse safety audit. Failure to comply with safety regulations and neglecting to address hazards can result in fines, penalties, legal liabilities, and potential lawsuits in case of accidents or injuries. It is essential to prioritize safety and ensure regular audits are conducted to avoid such legal complications.

When it comes to warehouse operations, there are many factors that contribute to efficiency and productivity. One often overlooked aspect is the importance of proper ergonomics. In a fast-paced environment where workers are constantly moving and handling heavy loads, it's crucial to prioritize the well-being and safety of employees. HCO Innovations, a leading management consulting firm specializing in warehouse optimization and forklift fleet management, understands the significance of incorporating ergonomic principles into warehouse operations.

The Impact of Ergonomics on Warehouse Operations

Ergonomics refers to the design and arrangement of workspaces, equipment, and systems that fit the individuals who use them. In the context of a warehouse, this means creating an environment that minimizes the risk of injuries, reduces physical strain, and enhances worker comfort. Implementing proper ergonomics can have a significant impact on various aspects of warehouse operations, including:

- Employee Safety: By ensuring that workstations, equipment, and tools are ergonomically designed, the risk of common workplace injuries such as musculoskeletal disorders, repetitive strain injuries, and back problems can be greatly reduced. By prioritizing employee safety, warehouse operations can maintain a healthy workforce and minimize downtime due to injuries.

- Productivity: Ergonomic improvements can lead to increased productivity in the warehouse. When employees are working in a comfortable and efficient manner, they can perform tasks more quickly and with less fatigue. Properly designed workstations and equipment can reduce the amount of time spent on each task, improving overall operational efficiency.

- Accuracy: When workers are physically comfortable and not experiencing discomfort or pain, they are more likely to maintain focus and pay attention to detail. This can result in a higher level of accuracy in handling inventory, picking orders, and navigating the warehouse. In turn, this reduces the likelihood of errors, such as mislabeled or misplaced products.

- Employee Morale: Taking care of employee well-being and providing ergonomic workstations sends a message that the company values its workforce. When employees feel supported and comfortable in their working environment, their overall job satisfaction and morale increase. This positive work environment fosters a stronger sense of teamwork and commitment to achieving the company's goals.

Implementing Ergonomics in the Warehouse

Now that we understand the importance of ergonomics in warehouse operations, let's explore some practical strategies for implementing ergonomic principles:

- Evaluate Workstations: Assess the design and layout of workstations to ensure they are ergonomic. This includes considering factors such as work surface height, chair ergonomics, and proper lighting. Make adjustments to accommodate the specific needs of different tasks and employees.

- Invest in Ergonomic Equipment: Upgrade to ergonomic equipment that promotes proper body mechanics. This includes tools such as adjustable height workbenches, ergonomic pallet jacks, and lifting aids. These investments can improve employee comfort and reduce the risk of injuries.

- Provide Training: Educate employees on proper lifting techniques, body mechanics, and the importance of taking breaks to avoid physical strain. Regular training sessions can reinforce safe practices and ensure that employees are aware of the potential risks associated with improper ergonomics.

- Promote Movement: Encourage employees to take regular breaks and stretch throughout their shifts. Incorporate rotation of tasks and offer opportunities for seated or standing work options. This helps reduce the strain on specific muscle groups and improves blood circulation.

- Utilize Technology: Leverage advanced technology solutions, such as warehouse management systems and automation, to streamline processes and reduce the physical strain on workers. These technologies can help optimize workflows, reduce manual handling, and enhance overall efficiency.

Partner with HCO Innovations for Ergonomic Warehouse Optimization

HCO Innovations is a trusted partner in warehouse optimization, and they understand the significance of incorporating ergonomic principles into the design and management of warehouse operations. With their expertise in warehouse layout evaluation, safety assessments, and turnkey maintenance solutions, HCO Innovations can help your business achieve significant cost reductions, operational efficiency, and a safer work environment.

By leveraging advanced cost-tracking software and adopting a collaborative "boots on the ground" approach, HCO Innovations tailors solutions to meet the unique needs of their clients in industries like distribution, manufacturing, and food processing. Their comprehensive services, combined with a focus on ergonomic practices, consistently deliver exceptional return on investment.

When it comes to warehouse optimization and reducing material handling costs, prioritizing proper ergonomics is a game-changer. It not only improves the well-being and safety of employees but also enhances overall operational efficiency and productivity. Partnering with HCO Innovations can help your business achieve these goals and stay ahead in the competitive market.

Visit HCO Innovations to learn more about their warehouse optimization solutions and how they can help you implement proper ergonomics in your warehouse operations.