Inefficient warehouse layouts can hinder the smooth operation of your business, leading to delayed shipping and decreased productivity. To ensure that your warehouse operates at its highest potential, it is crucial to have a well-organized and optimized layout. In this article, we will discuss how you can create a warehouse layout that facilitates quick shipping, improving the overall efficiency of your operations.

1. Analyze Your Current Operations

Before making any changes to your warehouse layout, it is essential to assess your current operations and identify areas that need improvement. Evaluate your current storage capacity, workflow processes, and inventory management systems. This analysis will help you pinpoint bottlenecks, areas of congestion, and any redundancies in your operations.

2. Define Your Objectives

Once you have analyzed your current warehouse operations, define your objectives and set specific goals for your new layout. Determine how you want to enhance efficiency and prioritize quick shipping. Consider factors such as reducing travel time, minimizing errors, and eliminating unnecessary steps in the order fulfillment process. Setting clear objectives will guide your decision-making process as you optimize your warehouse layout.

3. Optimize Storage Space

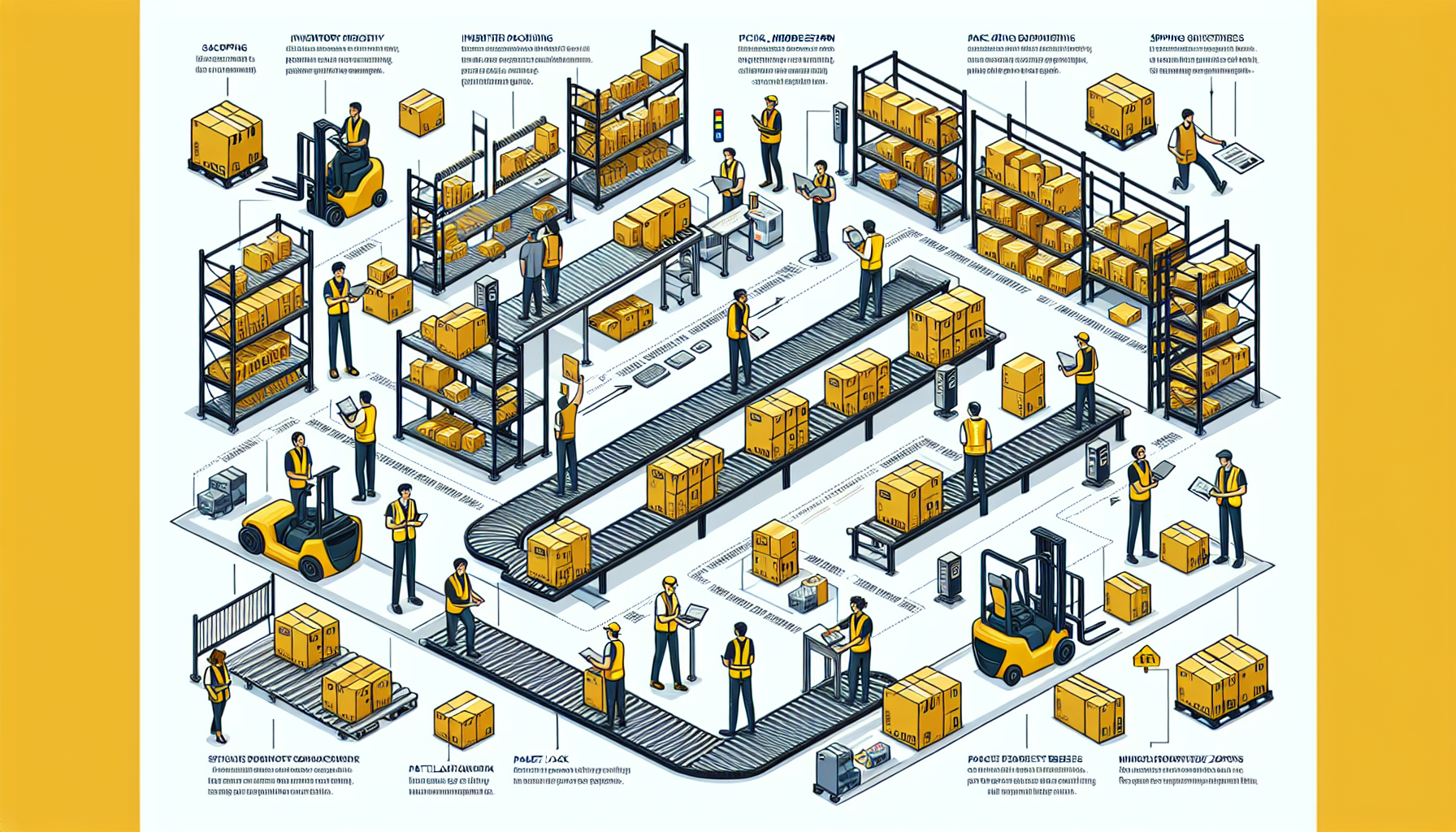

One of the main goals of a warehouse layout is to maximize storage space. Efficient use of your storage area can significantly improve the speed and accuracy of order fulfillment. Consider implementing the following strategies to optimize storage space:

- Utilize vertical space by installing high-density storage systems, such as pallet racking or mezzanine floors. These systems allow you to store goods vertically, making the best use of the available space.

- Implement an organized labeling system to quickly identify product locations. Clear signage and barcoding can help your warehouse personnel locate items faster, reducing picking errors and improving efficiency.

- Arrange your products based on their frequency of use. The items that are frequently picked should be placed closer to the shipping area, while less frequently accessed items can be stored further away.

4. Optimize Workflow

Streamlining your workflow is vital to achieving quick shipping in your warehouse. Consider the following strategies to optimize workflow:

- Create clear and logical paths for the movement of goods within your warehouse. Minimize the distance traveled by incorporating efficient flow patterns, such as a U-shaped or Z-shaped layout.

- Implement a pick-and-pack system to expedite the order fulfillment process. Group orders together based on their shipping destination to minimize travel time and increase efficiency.

- Use automation and technology solutions, such as conveyor systems and warehouse management systems, to streamline processes and reduce manual labor.

Implementing these workflow optimization strategies will help reduce picking and shipping errors, increase order accuracy, and ultimately facilitate quick shipping.

5. Consider Safety Measures

Creating a warehouse layout that prioritizes safety is crucial for both employees and the products being stored. Take the following safety measures into account:

- Ensure that your layout allows for clear aisles and pathways to avoid accidents and facilitate the movement of goods and equipment.

- Implement proper lighting and ventilation to create a safer and more comfortable working environment.

- Train your employees on proper lifting techniques and safe equipment operation to reduce the risk of accidents and injuries.

- Regularly inspect and maintain your equipment and storage systems to identify and address any potential hazards.

6. Continuously Monitor and Improve

Creating an optimized warehouse layout is not a one-time task. It requires constant monitoring and continuous improvement. Regularly evaluate your new layout to identify any areas that need adjustment or fine-tuning.

HCO Innovations provides warehouse optimization solutions that can assist you in creating an efficient and effective warehouse layout. They offer warehouse layout evaluation services to analyze your current operations and recommend improvements based on industry best practices. For more information, please visit HCO Innovations’ Warehouse Layout Evaluation.

By following these steps and considering the services provided by HCO Innovations, you can create a warehouse layout that facilitates quick shipping, leading to improved productivity, efficiency, and cost-effectiveness within your warehouse operations.