Warehouse safety is of utmost importance in any business or company that deals with the storage and movement of goods. It not only ensures the well-being and safety of employees but also helps maintain the integrity and efficiency of warehouse operations. To achieve and maintain a high level of safety in your warehouse, it is essential to create a comprehensive warehouse safety checklist. This checklist serves as a tool to identify potential hazards, assess safety measures, and implement necessary precautions. In this article, we will guide you on how to create an effective warehouse safety checklist to keep your warehouse safe and secure.

Understanding the Importance of a Warehouse Safety Checklist

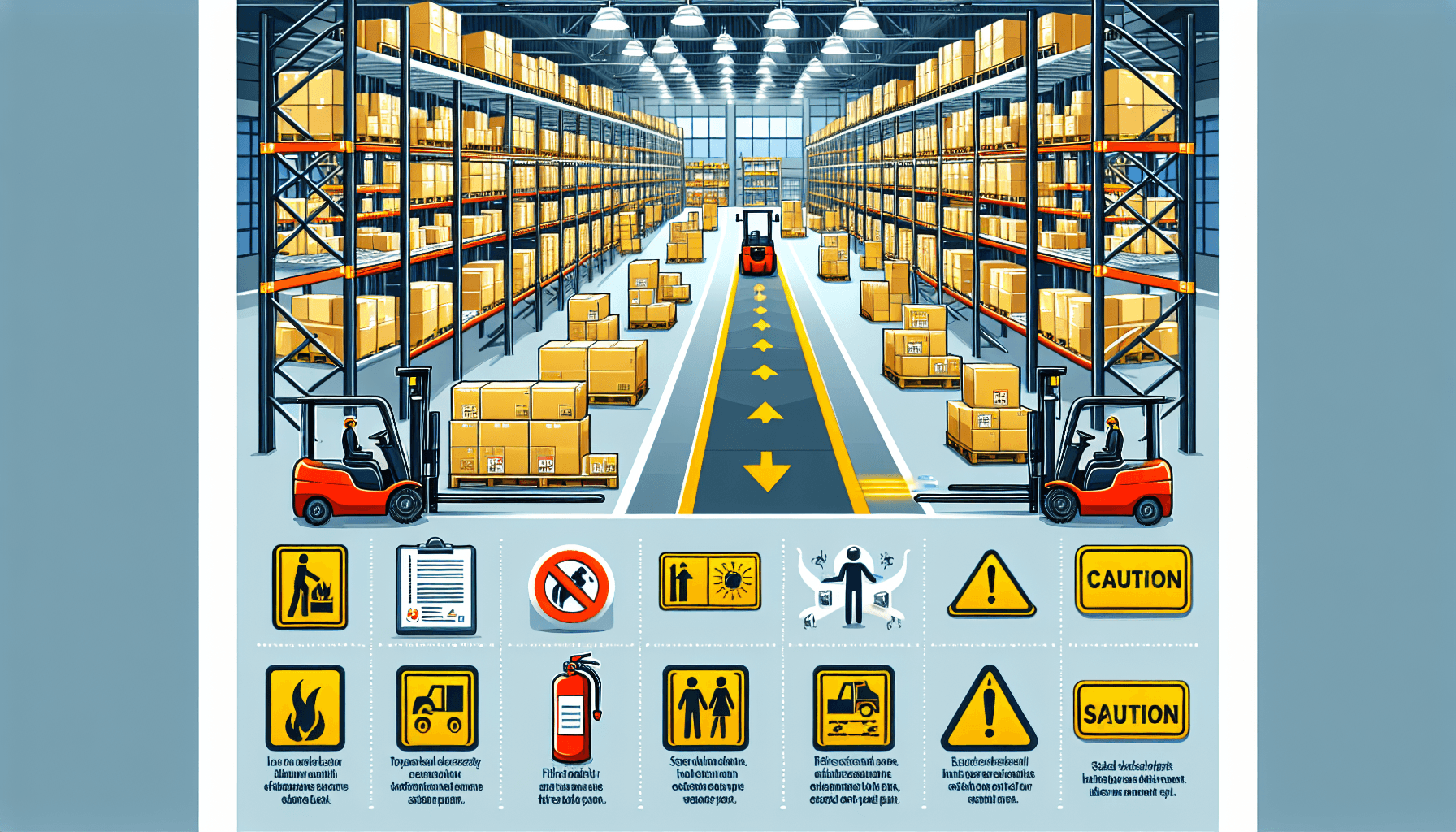

Before we dive into the steps of creating a warehouse safety checklist, let’s first understand why it is important. A warehouse is a dynamic environment with various activities occurring simultaneously, including storage, handling, and movement of goods, operation of machinery and equipment, and interaction among employees. With so many elements involved, the risk of accidents and injuries increases significantly if proper safety measures are not in place. A warehouse safety checklist acts as a proactive tool to identify potential hazards, assess the current safety status, and implement preventive measures to ensure the well-being of employees and the protection of inventory.

By conducting regular safety evaluations using a detailed checklist, you can identify potential risks and rectify them promptly. This proactive approach not only prevents accidents and injuries but also helps create a safety-conscious culture within the warehouse. Additionally, implementing a safety checklist can help your organization comply with legal regulations and standards governing workplace safety, protecting you from potential fines and legal consequences.

The Steps to Create an Effective Warehouse Safety Checklist

Now that we understand the importance of a warehouse safety checklist, let’s move on to the steps involved in creating one. Keep in mind that every warehouse is unique, and your checklist should be tailored to the specific needs and risks of your operation. However, the following steps will generally apply to most warehouses.

1. Identify Potential Hazards

The first step in creating a warehouse safety checklist is to identify potential hazards specific to your warehouse. Walkthrough the entire warehouse and observe all areas, including storage areas, aisles, loading docks, machinery and equipment, electrical systems, and employee workstations. Look for any potential hazards such as poor lighting, slippery floors, improperly stored items, dangerous machinery, electrical hazards, or any other factors that may pose a risk to the safety of employees or the integrity of inventory.

Once you have identified the potential hazards, make a comprehensive list and categorize them based on priority and severity. This prioritization will help you allocate resources and address the most critical issues first.

2. Research Applicable Safety Regulations and Standards

The next step is to research and familiarize yourself with the applicable safety regulations and standards governing warehouse operations. These may vary depending on your location and the nature of your business. Some common regulations include the Occupational Safety and Health Administration (OSHA) standards in the United States and similar regulatory bodies in other countries. Understand the requirements and recommendations outlined in these regulations and use them as a baseline in creating your warehouse safety checklist.

It is important to note that compliance with these regulations is not solely driven by legal obligations but mainly by the desire to ensure the safety and well-being of your employees. In doing so, you create a work environment where employees feel valued and protected, leading to increased productivity and overall job satisfaction.

3. Involve Your Warehouse Staff

Your warehouse staff plays a crucial role in identifying potential safety hazards. They are the ones working in the warehouse day in and day out, and they have first-hand experience and knowledge of the challenges and risks involved. Include your warehouse staff in the process of creating the safety checklist by seeking their input and insights. Conduct brainstorming sessions or anonymous suggestion boxes to gather their ideas and suggestions for improving warehouse safety.

By involving your warehouse staff, you not only tap into their expertise but also create a sense of ownership and responsibility towards maintaining a safe working environment. Encourage open communication and provide channels for reporting safety concerns or incidents. This collaborative approach fosters a culture of continuous improvement and ensures that everyone is invested in maintaining a safe and secure warehouse.

4. Create a Comprehensive Checklist

With all the information gathered from identifying potential hazards, researching applicable safety regulations, and involving your warehouse staff, it’s time to create a comprehensive warehouse safety checklist. The checklist should cover all aspects of warehouse operations and address potential hazards, preventive measures, and emergency procedures.

Consider including the following areas in your checklist:

- Storage and shelving safety

- Material handling equipment safety

- Electrical safety

- Fire safety

- Emergency response procedures

- Personal protective equipment (PPE) requirements

- Training and education programs

For each area, specify the safety measures or protocols that need to be followed and provide clear instructions or guidelines for implementation. Use language that is easy to understand and ensure that the checklist is easily accessible to all employees.

Additionally, consider incorporating best practices and recommendations from industry experts or consultants who specialize in warehouse safety. They can provide valuable insights and suggestions to enhance the effectiveness of your checklist.

5. Implement and Evaluate

Once your warehouse safety checklist is created, it’s time to implement it in your operations. Train your employees on the checklist and ensure they understand its purpose and importance. Conduct regular safety inspections and assessments to ensure compliance with the checklist and identify any gaps or areas for improvement.

Continuous evaluation and improvement are key to maintaining a safe warehouse environment. Regularly review and update the checklist based on changes in regulations, industry best practices, or feedback from employees. Use incidents or near-misses as learning opportunities to revise and strengthen your safety protocols. Additionally, encourage open communication and feedback from your warehouse staff to address any emerging safety concerns promptly.

Remember, creating a warehouse safety checklist is not a one-time task but an ongoing process that requires constant attention and dedication. By prioritizing safety and implementing a comprehensive checklist, you are taking proactive steps to protect your employees, inventory, and business reputation.

To further enhance your warehouse safety practices, consider partnering with a professional consultant or safety organization, like HCO Innovations, who can conduct a thorough evaluation of your warehouse operations and provide guidance on implementing best practices. They offer warehouse safety evaluations and comprehensive solutions to improve safety and compliance. Check out their website for more information: HCO Innovations.

Conclusion

Creating a warehouse safety checklist is a vital step in ensuring the well-being of your employees and maintaining the efficiency of your operations. By following the steps outlined in this article, you can develop a comprehensive checklist that covers all potential hazards, complies with safety regulations, and engages your warehouse staff. Remember, safety is an ongoing process, so regularly evaluate and update your checklist to address changing circumstances and emerging risks. Prioritize warehouse safety, and you’ll create a secure and productive environment that benefits everyone involved.

What is a warehouse safety checklist?

A warehouse safety checklist is a comprehensive list of safety measures and protocols that should be followed to ensure a safe working environment in a warehouse facility. It typically includes items such as equipment maintenance, proper use of personal protective equipment (PPE), housekeeping, emergency procedures, and more.

Why is it important to have a warehouse safety checklist?

Having a warehouse safety checklist is crucial to promote a safe working environment and minimize the risk of accidents, injuries, and property damage. It helps to identify potential hazards, ensure compliance with safety regulations, and establish a culture of safety awareness among employees.

How can I create a warehouse safety checklist?

To create a warehouse safety checklist, you should start by conducting a thorough assessment of the warehouse and identifying potential hazards. Next, research applicable safety regulations and industry best practices to ensure your checklist covers all relevant areas. Consider involving employees and safety experts to gather input and expertise. Finally, organize the checklist into categories or sections, and regularly review and update it as needed.

What should be included in a warehouse safety checklist?

A warehouse safety checklist should include items such as equipment inspections, proper storage protocols, fire safety measures, housekeeping procedures, electrical safety checks, material handling guidelines, personal protective equipment requirements, emergency procedures, and employee training programs.

How often should I review and update the warehouse safety checklist?

It is recommended to review and update the warehouse safety checklist on a regular basis. This could be annually, semi-annually, or whenever there are major operational changes or incidents. Keeping the checklist up-to-date ensures that it remains relevant to the evolving needs and changing regulations of your warehouse facility.

Where can I find templates or examples of a warehouse safety checklist?

There are various resources available online where you can find templates or examples of warehouse safety checklists. You can search for industry-specific templates, safety organization websites, or consult with safety professionals who specialize in the warehousing industry. These resources can provide you with a starting point and help you customize the checklist to suit your specific warehouse needs.

How can I ensure employees follow the warehouse safety checklist?

To ensure employees follow the warehouse safety checklist, it is important to provide proper training and education. Conduct regular safety meetings and sessions to emphasize the importance of safety protocols and explain the potential risks of non-compliance. Encourage employee involvement and engagement by seeking their feedback and suggestions for improving safety practices. Implement a system of rewards and consequences to incentivize compliance and hold employees accountable for adhering to the checklist.

Are there any legal requirements for a warehouse safety checklist?

Legal requirements for a warehouse safety checklist can vary depending on your location and industry. It is important to research and understand the local, state, and federal regulations that apply to your warehouse facility. Consulting with legal professionals or safety organizations specializing in your industry can help ensure your checklist meets all necessary legal requirements.

In the fast-paced world of warehouse operations, it's essential to have a solid daily inspection routine in place. A well-designed routine helps ensure that your warehouse is running smoothly, maximizes efficiency, and reduces the risk of accidents or equipment failures. In this article, we will discuss the importance of developing a daily warehouse inspection routine and provide some best practices to help you implement one effectively.

Why is a Daily Warehouse Inspection Routine Important?

A daily inspection routine is crucial for maintaining the safety and efficiency of your warehouse operations. It allows you to identify and address potential issues before they escalate into larger problems that can disrupt productivity and lead to costly downtime. By conducting regular inspections, you can:

- Ensure Safety: A daily inspection routine helps you identify any hazards or safety risks in your warehouse, such as damaged racking, blocked emergency exits, or malfunctioning forklifts. Addressing these issues promptly can prevent accidents and create a safer work environment for your employees.

- Maintain Equipment: Regular inspections allow you to check the condition of your warehouse equipment, including forklifts, conveyors, pallet jacks, and other machinery. By identifying any signs of wear and tear or potential defects, you can schedule timely maintenance or repairs, extending the lifespan of your equipment and reducing the risk of breakdowns.

- Optimize Efficiency: A well-maintained warehouse is a more efficient warehouse. A daily inspection routine helps you identify any inefficiencies in your operations, such as poor layout design, congested aisles, or storage capacity issues. By addressing these issues, you can streamline your processes and maximize productivity.

- Ensure Compliance: Regular inspections help you ensure that your warehouse is compliant with industry regulations and safety standards. By identifying any non-compliant areas or practices, you can take the necessary steps to rectify them and avoid potential penalties.

Implementing a Daily Warehouse Inspection Routine

Developing and implementing a daily warehouse inspection routine requires careful planning and attention to detail. Here are some best practices to help you get started:

- Create a Checklist: Develop a comprehensive checklist that covers all the critical areas of your warehouse. This checklist should include items such as checking for damaged racking, inspecting fire extinguishers, examining emergency exit routes, and assessing equipment conditions. Having a checklist will ensure that you don't overlook any important areas during your inspections.

- Assign Responsibilities: Designate specific individuals or teams responsible for conducting daily inspections. This ensures accountability and makes it easier to track progress and address any issues that arise during the inspections.

- Establish a Schedule: Determine the frequency of your daily inspections based on the size and complexity of your warehouse operations. Smaller warehouses may require inspections once a day, while larger facilities may need inspections multiple times a day. Establish a clear schedule and communicate it with all relevant personnel.

- Train and Educate: Provide thorough training to your inspection teams on what to look for and how to document their findings. It's essential that they understand the importance of their role in maintaining warehouse safety and efficiency. Regularly update their training to keep them informed about any new developments or best practices.

- Document and Report: Ensure that all inspection findings are documented and reported accurately. Utilize technology, such as digital inspection forms or software, to streamline the process and centralize information. This allows you to track trends, prioritize maintenance or repairs, and demonstrate compliance if required.

- Take Action: Once an issue is identified during the inspection, it's essential to take prompt action to address it. Whether it's scheduling maintenance, ordering replacement parts, or reorganizing warehouse layout, make sure the necessary steps are taken to rectify the problem efficiently.

By following these best practices, you can develop a robust daily warehouse inspection routine that keeps your operations running smoothly and minimizes any disruptions or potential risks.

At HCO Innovations, we understand the importance of maintaining a well-structured warehouse inspection routine. Our comprehensive services, including warehouse layout evaluation, safety assessments, and turnkey maintenance solutions, can help optimize your warehouse operations and reduce material handling costs. With our advanced cost-tracking software and collaborative approach, we provide tailored solutions that deliver exceptional return on investment. Trust us to be your partner in achieving cost reductions and operational efficiency in your warehouse.

In conclusion, developing a daily warehouse inspection routine is paramount for the safety, efficiency, and compliance of your warehouse operations. By implementing a structured routine, assigning responsibilities, and documenting findings, you can identify and address potential issues proactively. Remember, a well-maintained warehouse is a productive warehouse.